Hydraulic spring automatic hydraulic load-variable device

A hydraulic spring and variable loading technology, applied in fluid pressure actuators, grain processing, servo motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention adopts the system analysis and design concept that one unit is equipped with a set of hydraulic oil station, the transformation cost is low, the equipment maintenance amount is small, the structure is simple and reliable, and some devices with constant loading are reserved, which can better adapt to the change of unit load , to meet a wider range of load changes.

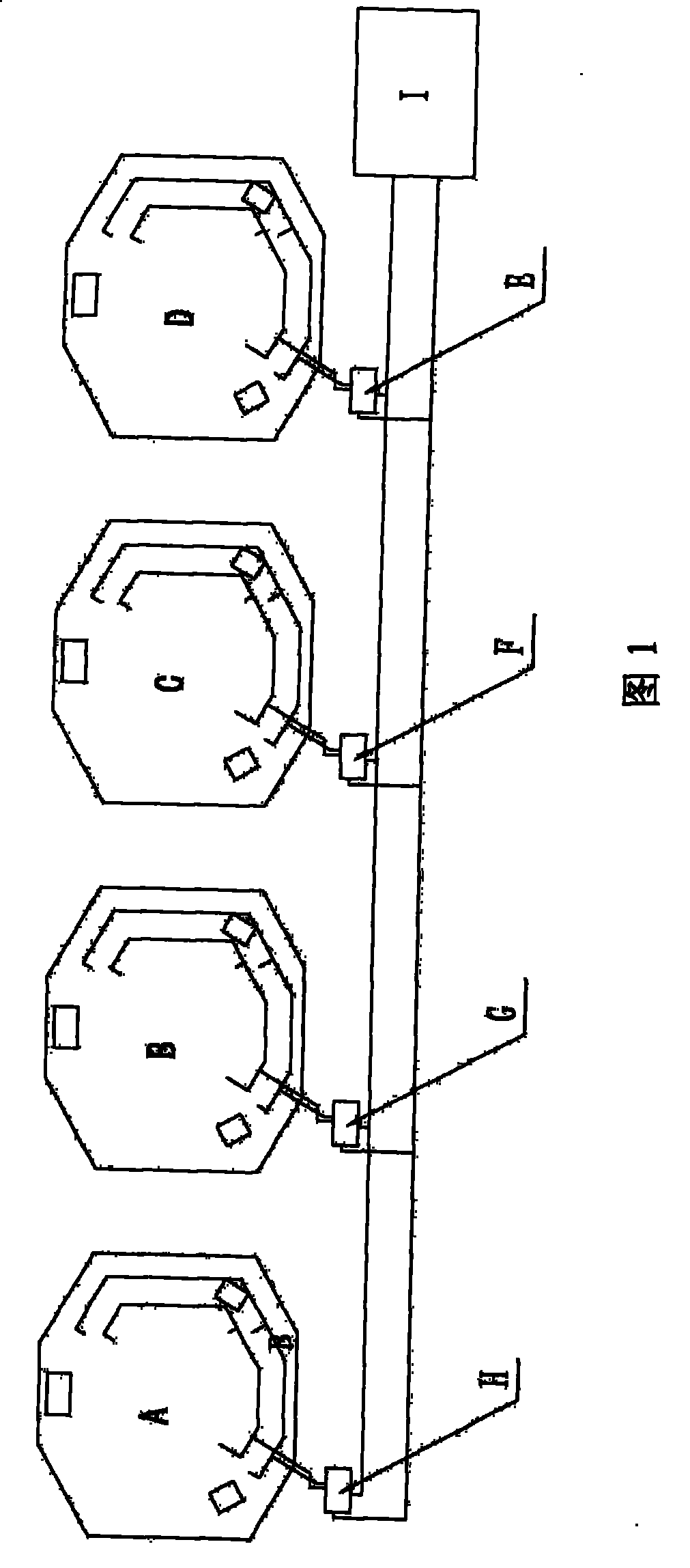

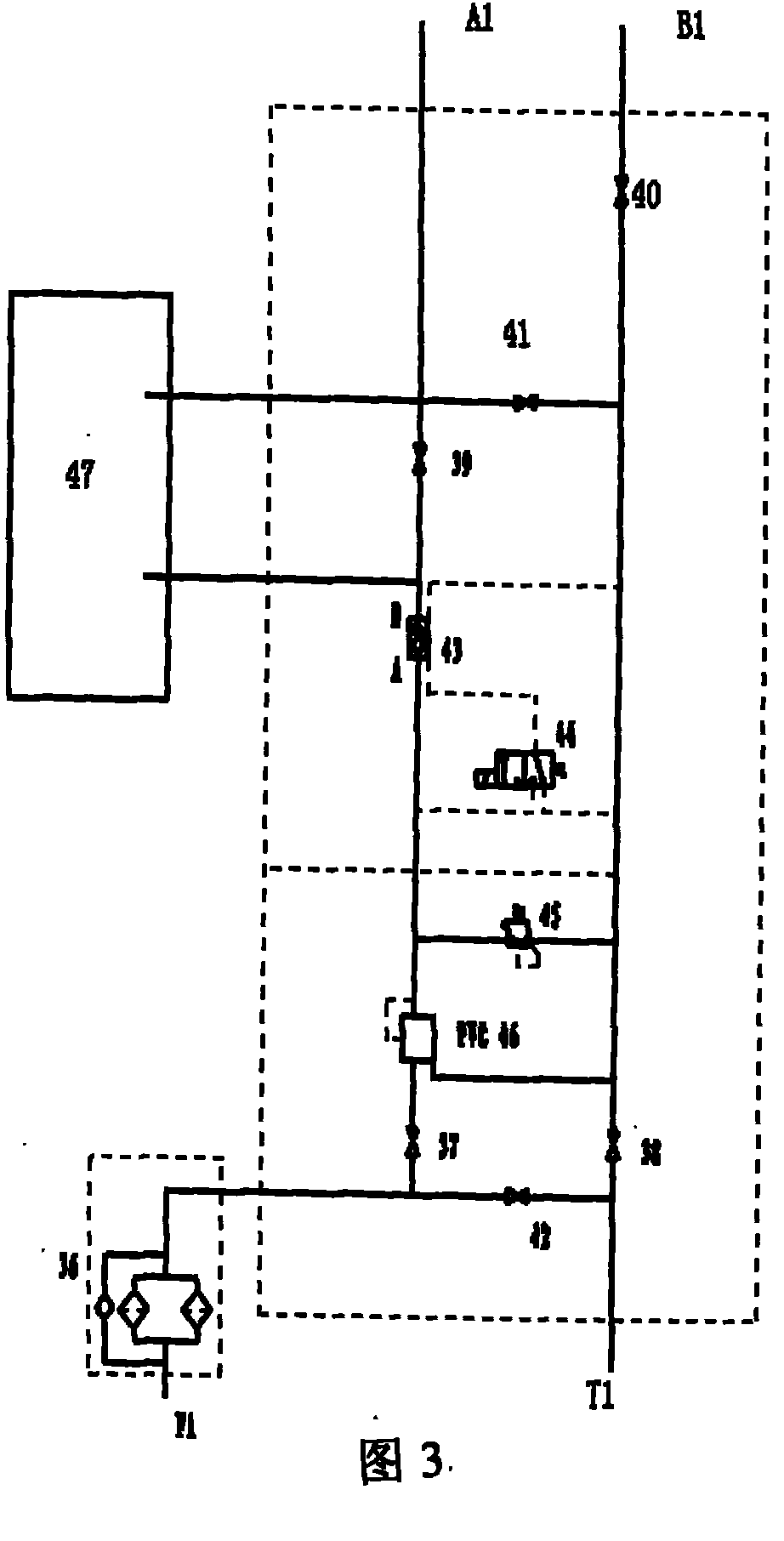

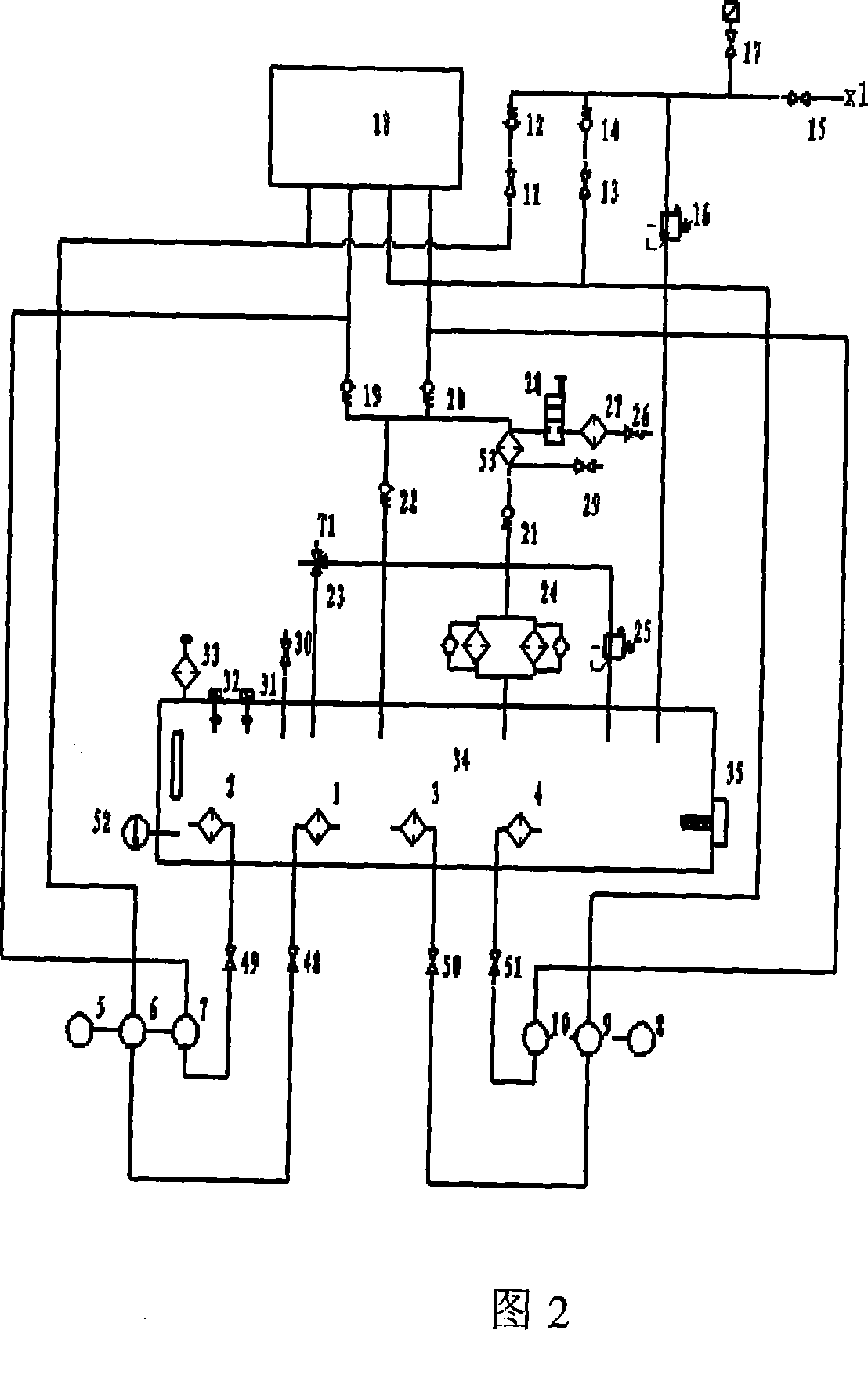

[0016] This set of hydraulic spring automatic variable loading device adopts a central power unit with double pumps, and is connected with a separate valve station corresponding to each coal mill. Stainless steel pipes connect the valve station to the three hydraulic cylinders at the bottom of the coal mill. , the hydraulic cylinder is connected to the spring frame of the coal mill through the loading rod next to the coal mill. When the hydraulic pressure from the central power unit is applied to the upper part of the hydraulic cylinder through the valve station, the loading rod moves do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com