Spin coating production method of love wave sensor PMMA wave-guide membrane

A sensor and waveguide technology, which is applied in the field of preparation of PMMA waveguide films for Love wave sensors, can solve the problems of poor internal uniformity, many defects, and difficulty in obtaining, and achieves good flatness and uniformity, good flatness and uniformity, Moderately volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The spin-coating preparation method of a kind of Love wave sensor polymethyl methacrylate (PMMA) waveguide film provided by the present invention is as follows (example):

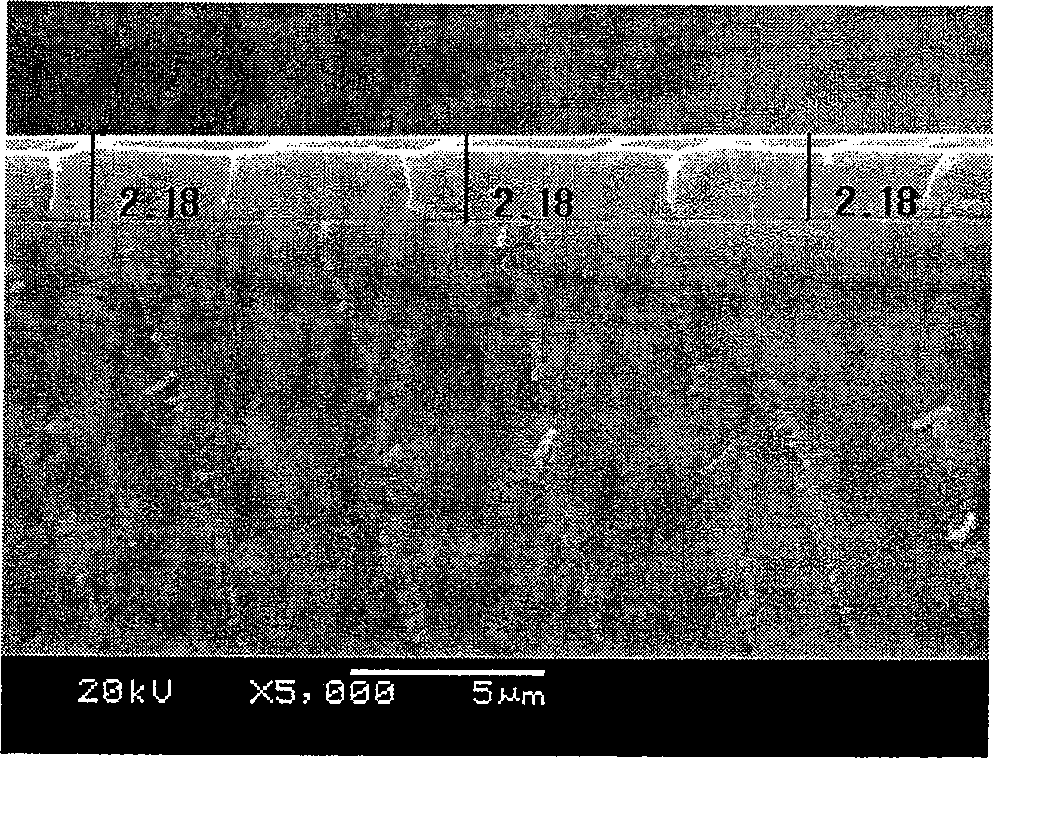

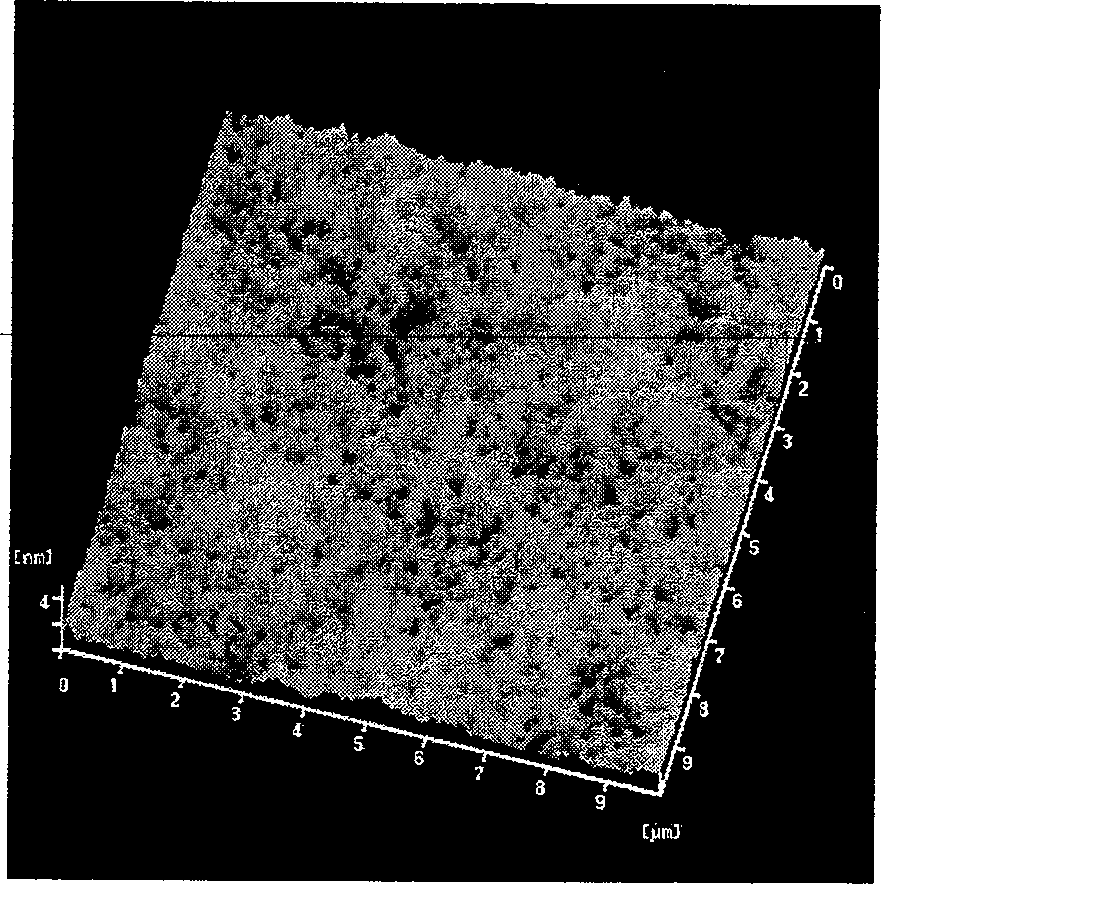

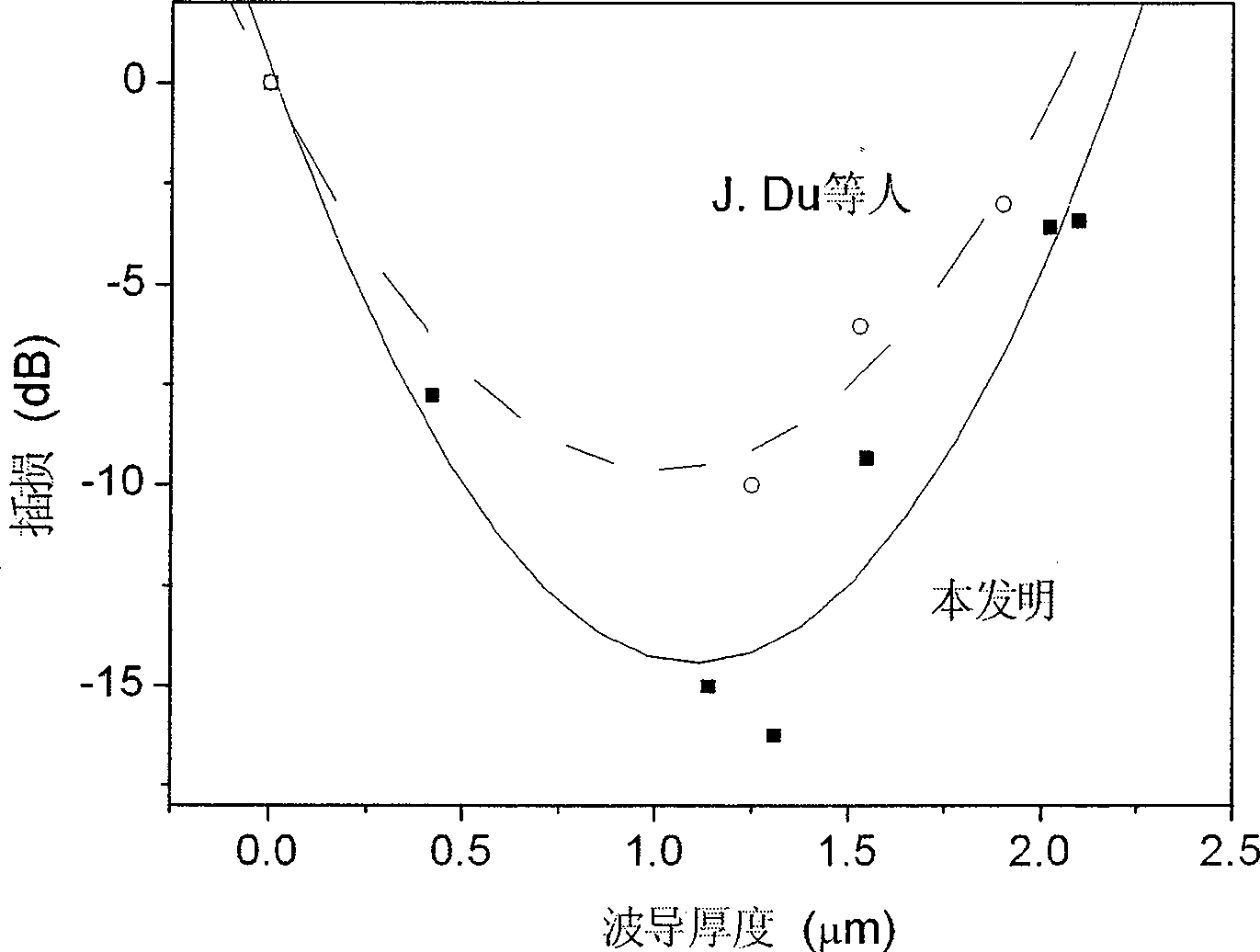

[0017] The surface shallow body wave (SSBW) device is self-made in the laboratory, the piezoelectric chip is made of ST quartz, the interdigitated electrode (IDT) is made of an aluminum electrode with a double-terminal resonant structure, and then the PMMA waveguide is spin-coated on it to complete the Love wave device. preparation. The molecular weight of the PMMA raw material is 35,000, and 1,2-dichloroethane is used as a solvent to prepare a solution with a concentration of 4 wt%, and then spin-coat it on the SSBW device at a speed of 2,000 rpm for 180 s. According to the required thickness, repeat the spin coating several times, and then cure at 180°C for 120 minutes to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com