Cleaning liquid for plasma etching residue

A technology of etching residue and cleaning solution, applied in the field of cleaning solution, can solve the problems of small cleaning window, large corrosion rate, insufficient cleaning ability, etc., and achieve the effect of large operating window and strong cleaning ability

Inactive Publication Date: 2009-04-22

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The technical problem to be solved by the present invention is to overcome defects such as high corrosion rate, inability to simultaneously control metal and non-metal corrosion, small cleaning window, insufficient cleaning ability and unstable cleaning effect in the existing plasma etching residue cleaning solution. , and provide a plasma etching residue cleaning solution with strong cleaning ability, low corrosion rate, simultaneous control of metal and non-metal corrosion, large cleaning window, and stable cleaning effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

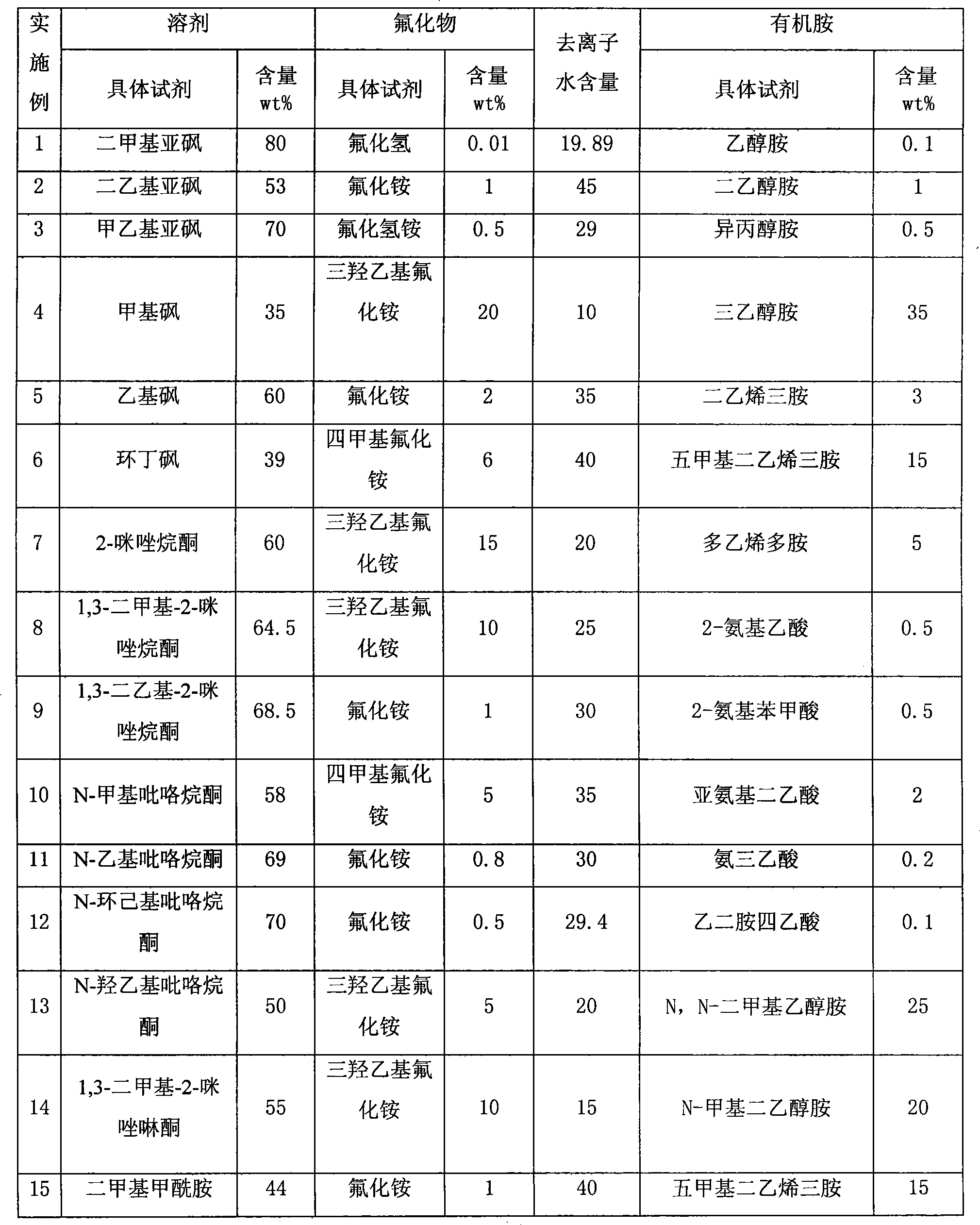

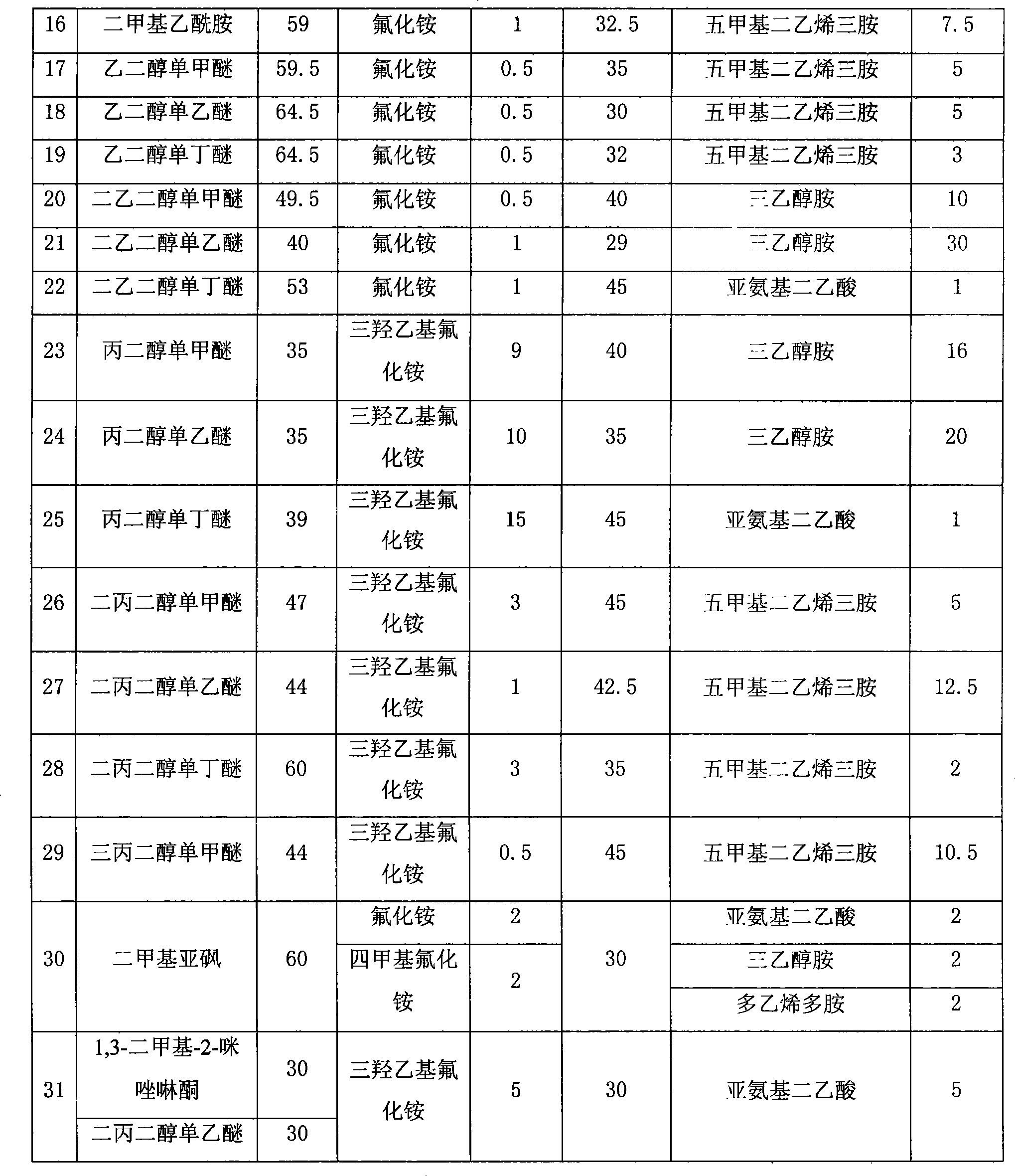

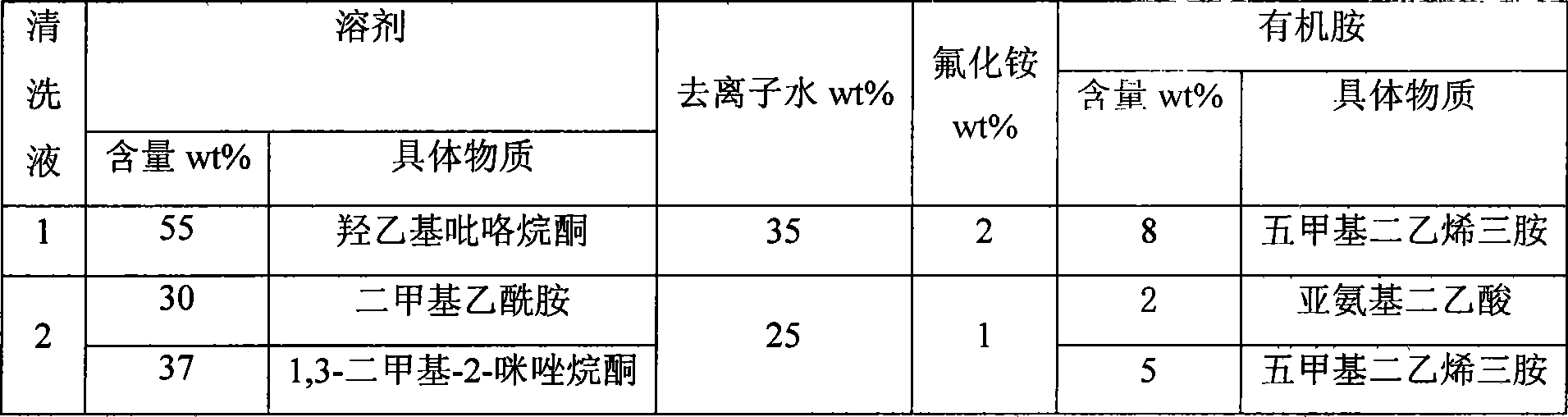

Embodiment 1~31

[0017] Table 1 shows Examples 1-31 of the plasma etching residue cleaning solution of the present invention. According to the formula in the table, the components are uniformly mixed to prepare the cleaning solution of each embodiment.

[0018] Table 1 Plasma etching residue cleaning solution 1-31 of the present invention

[0019]

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a plasma etching remainder detergent, which contains fluoride, organic amine, a solvent and water. The detergent has strong washing capability, can effectively remove plasma etching remainder on a metal wire (Metal), a channel (Via) and a metal pad (Pad) wafer, has smaller etching speed to non-metal materials (such as SiO2, ion enhanced tetraethoxy silane silicon dioxide (PETEOS), silicon, low dielectric material and the like), partial metal materials (such as Ti, Al and Cu) and so on, can be used for batch immersion type cleaning mode, batch rotation spray type cleaning mode and uniwafer rotation type cleaning mode, has larger operation window, and has excellent application prospect in semiconductor wafer cleaning and other micro-electronic fields.

Description

technical field [0001] The invention relates to a cleaning solution in a semiconductor manufacturing process, in particular to a plasma etching residue cleaning solution. Background technique [0002] In the manufacturing process of semiconductor components, the coating, exposure and imaging of photoresist layers are necessary process steps for the pattern manufacturing of components. Residues of photoresist material need to be completely removed at the end of patterning (ie, after photoresist coating, imaging, ion implantation, and etching) before proceeding to the next process step. Ion bombardment during the doping step hardens the photoresist polymer, thus making the photoresist less soluble and thus more difficult to remove. To date, a two-step process (dry ashing and wet etching) has generally been used in the semiconductor manufacturing industry to remove this photoresist film. The first step removes most of the photoresist layer (PR) by dry ashing. The second step...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D7/32G03F7/42C11D3/02

CPCC11D7/28G03F7/425C11D7/3209C11D7/5004C11D11/0047G03F7/423C11D2111/22

Inventor 刘兵彭洪修于昊

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com