Vacuum decomposing apparatus for separating gallium arsenide as metal gallium and metal arsenic

A technology of metal gallium and gallium arsenide, which is applied in the field of vacuum decomposition devices, can solve the problems of increasing the difficulty of the operator's work, the low decomposition rate of gallium arsenide, and the lack of collection of arsenic, so as to facilitate subsequent utilization, improve the decomposition rate, The effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

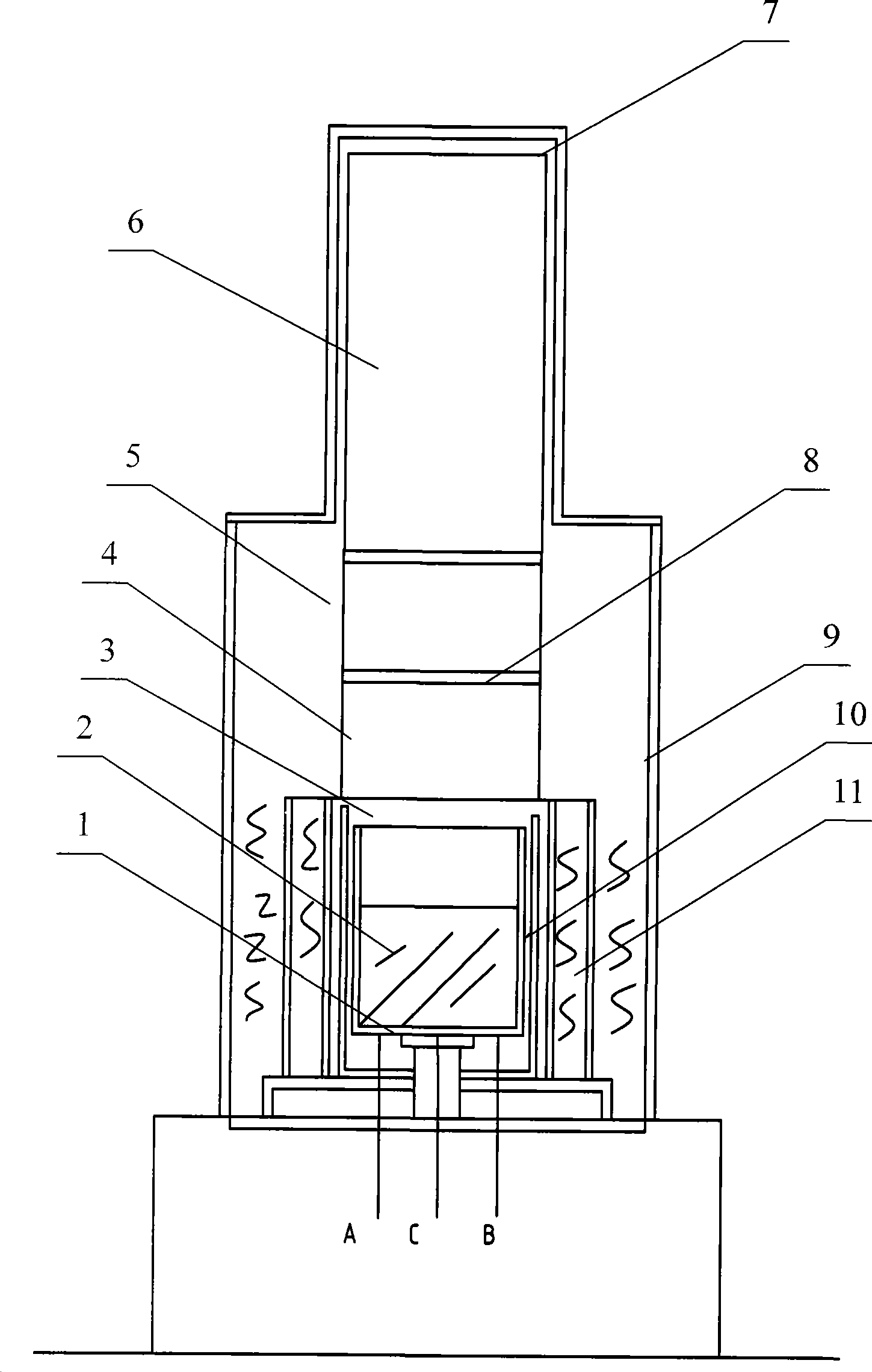

[0015] Embodiment 1: as figure 1 As shown, a vacuum decomposition device for separating gallium arsenide into metal gallium and metal arsenic includes a vacuum furnace body 9 provided with a cooling device, and the inside of the vacuum furnace body 9 is divided into a heating zone 3, a buffer Zone 5, cooling zone 7, the buffer zone 5 is provided with an arsenic vapor conduit 4 placed on the top of the heating zone 3 for providing an ascending passage for the arsenic vapor; Connected arsenic collection blind pipe 6, a buffer baffle 8 with holes is provided in the arsenic vapor conduit 4 to slow down the rising speed of arsenic vapor evaporation and increase the number of buffer baffles 8 as needed; the heating Zone 3 is composed of a crucible 10, a heater 1, and an insulating layer 11. The crucible 10 is made of graphite and is used to place gallium arsenide 2 to be separated. The heater 1 is a three-phase alternating current heater, and the partially decomposed gallium metal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com