Double-layer low-position vacuum preload consolidation device and soft soil foundation reinforcing method

A technology of soft soil foundation and reinforcement device, which can be used in soil protection, infrastructure engineering, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

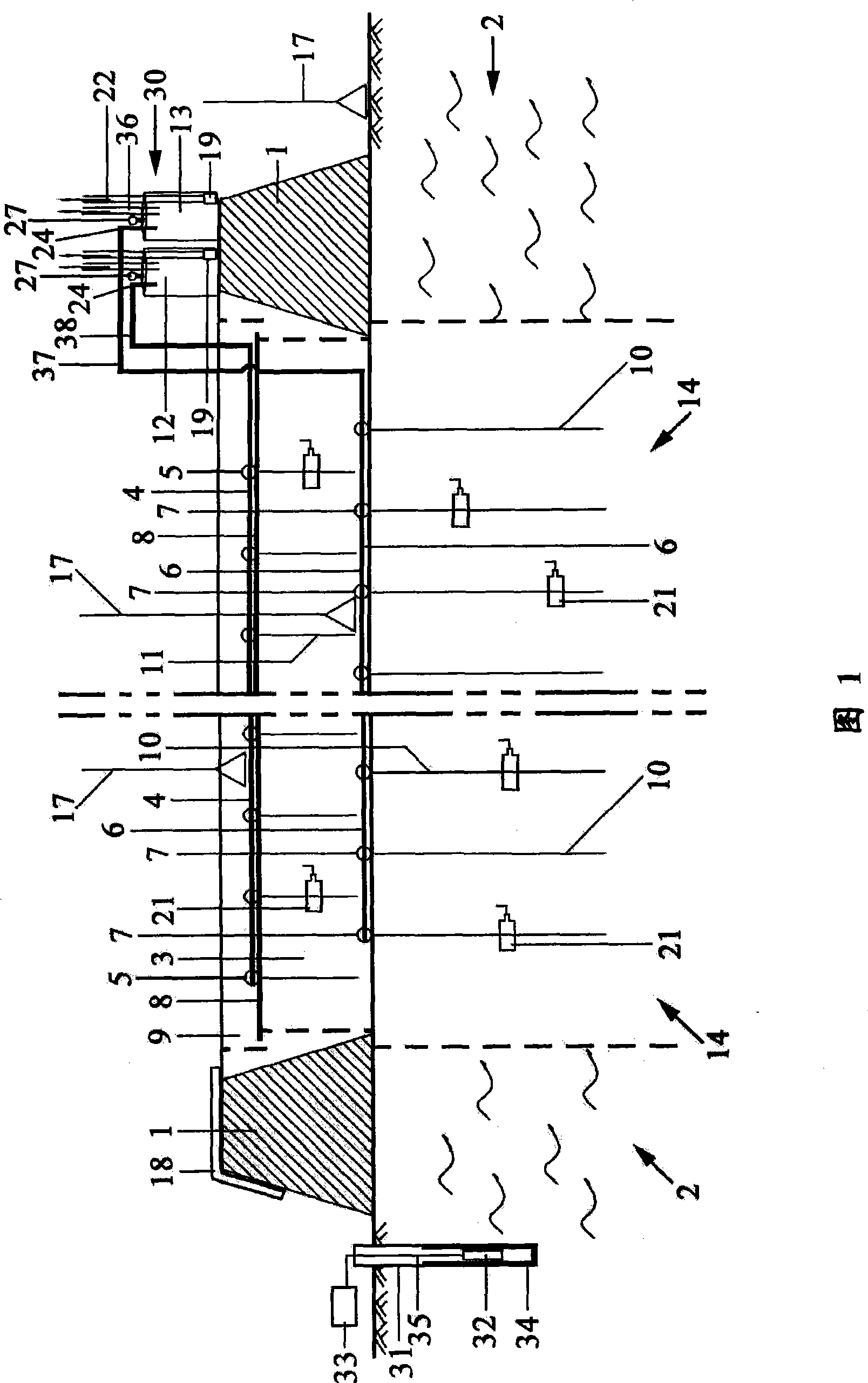

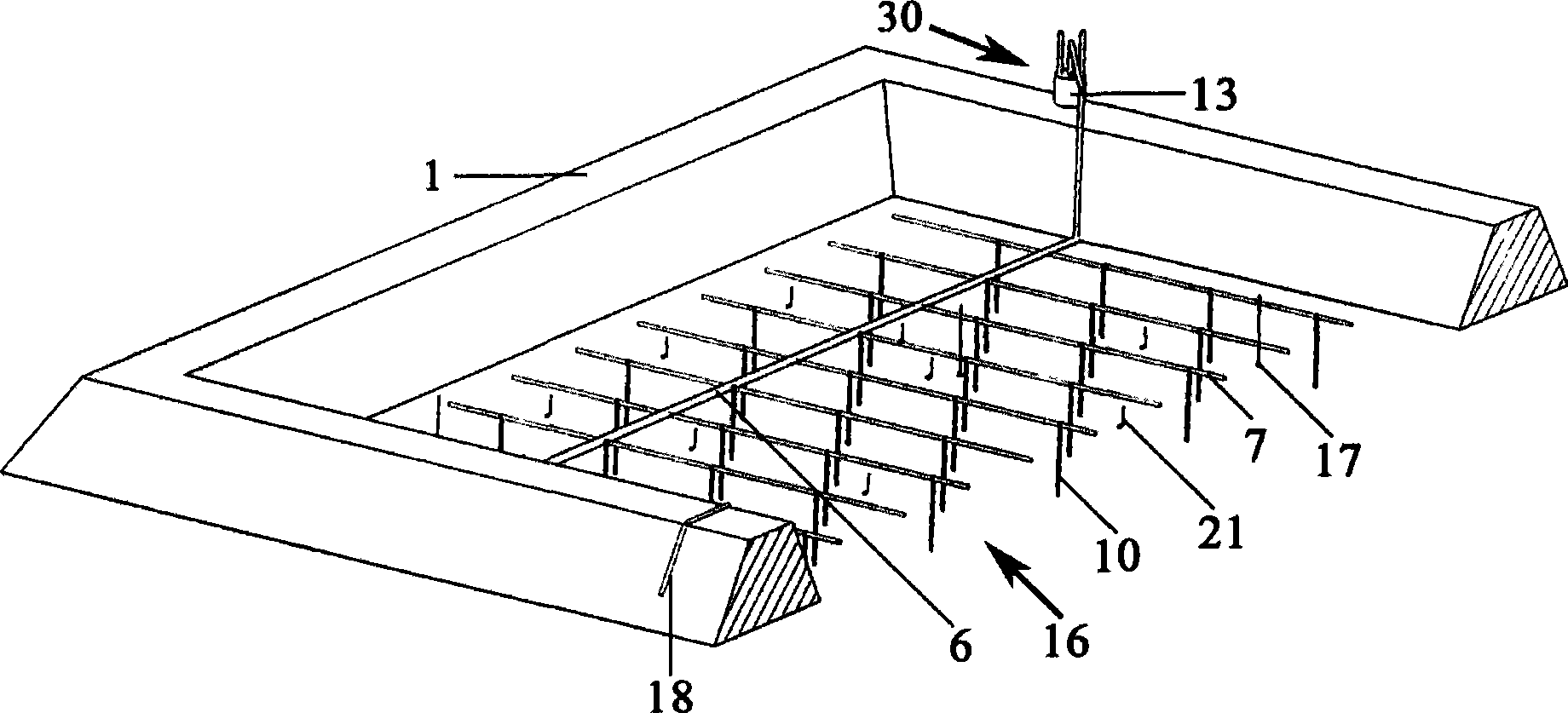

[0130] It consists of a main controller, a power distribution controller, a vacuum pump (20), a submersible pump (19), a buffer separation tank (30), a control valve (26), a vacuum gauge (27), a vacuum degree probe (21), blowing and filling Reinforcement layer vacuum pipe network (15), soft soil reinforcement layer vacuum pipe network (16), settlement mark (17), open water overflow (18), pipeline and meter (29), on the soft soil foundation (2) Set the boundary of the reinforcement area, fill the cofferdam (1) along the boundary of the reinforcement area, form a soft soil reinforcement layer (14) in the cofferdam (1), and place a settlement mark (17) on the soft soil foundation (2), at least 5 or more.

[0131] The soft soil reinforcement layer vacuum pipe network (16) is set on the soft soil reinforcement layer (14), the soft soil reinforcement layer vacuum pipe network (16) is in the form of a network as a whole, and the blow-fill reinforcement layer (3) is arranged on the so...

Embodiment 2

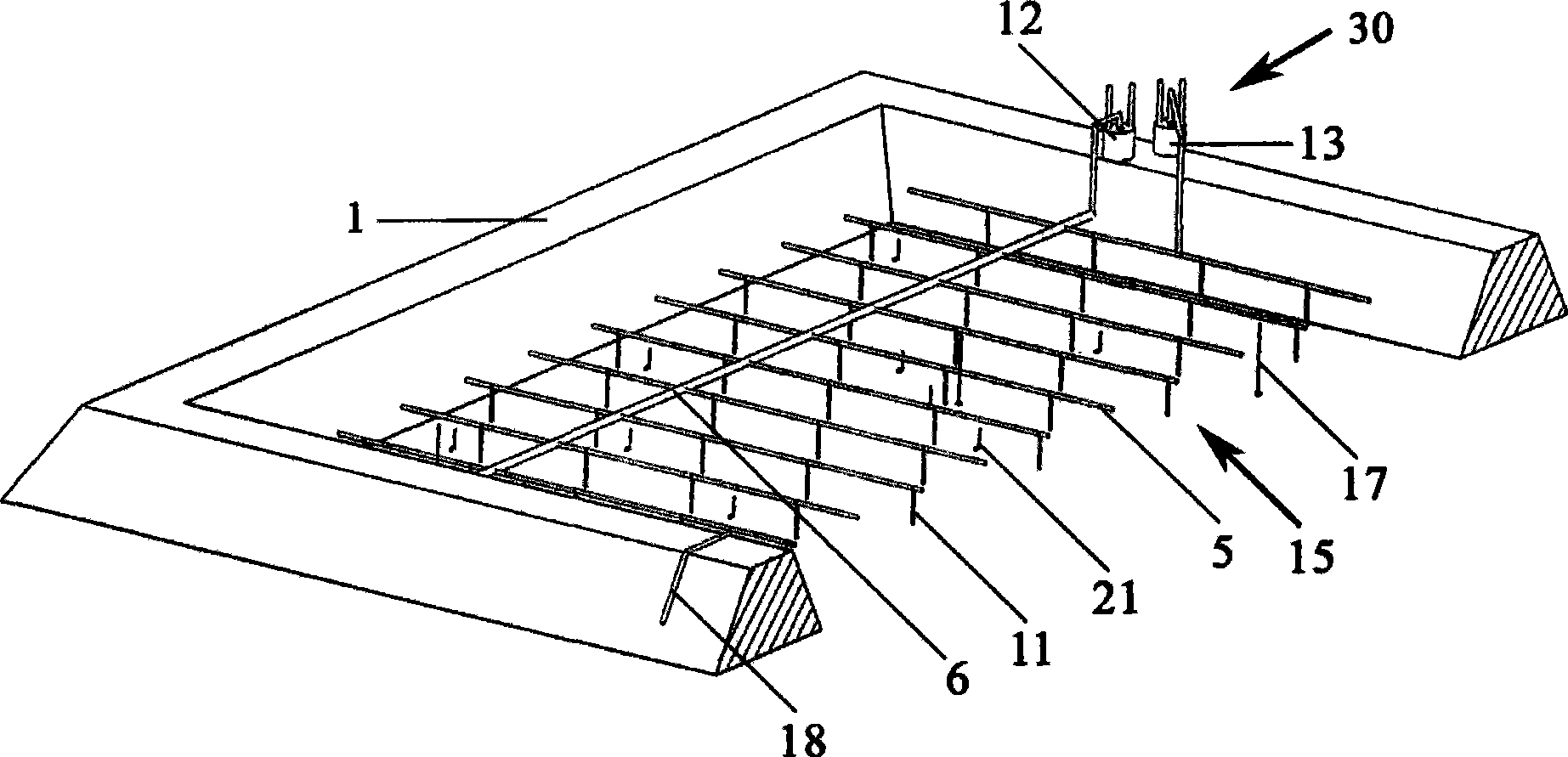

[0140] On the soft soil reinforcement layer (14) in the cofferdam (1), the dredging-fill reinforcement layer (3) is formed by dredging-filling of silt soil, and open water overflow outlets (18) are arranged around the top of the cofferdam (1), and at least 1 A clear water overflow port (18), the clear water that the dredging and filling silt soil separates out is discharged outside the cofferdam (1) through the clear water overflow port (18).

[0141] On the mud surface of the blow-fill reinforcement layer (3), lay geotextiles, bamboo and brambles repeatedly layer by layer to form a load-bearing isolation layer (8), at least 2 layers, geotextiles, bamboo and brambles to prevent mud from muddying and strengthen the load , enhance workability.

[0142] On the load-bearing isolation layer (8), the blow-fill reinforcement layer vacuum dry pipe (4) is horizontally arranged, at least one, and one end of the blow-fill reinforcement layer vacuum dry pipe (4) is connected with the blow...

Embodiment 3

[0155] The boundary of the reinforcement area is set on the soft soil foundation (2) according to the design drawing, and a cofferdam (1) is filled outside the boundary of the reinforcement area, and the area inside the cofferdam (1) is a soft soil reinforcement layer (14). Make the position of the drainage board (10) of the soft soil reinforcement layer and the position of the vacuum pipe network (16) of the soft soil reinforcement layer, and set up marks. Settlement markers (17) are placed on the soft soil foundation (2), at least 5 or more to monitor the settlement degree of the soft soil foundation (2).

[0156] In the soft soil reinforcement layer (14), insert the soft soil reinforcement layer drainage board (10) at equal distances and equal lengths, the lower end of the soft soil reinforcement layer drainage board (10) is closed, and penetrates longitudinally into the soft soil reinforcement layer (14) .

[0157] On the soft soil reinforcement layer (14), the vacuum bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com