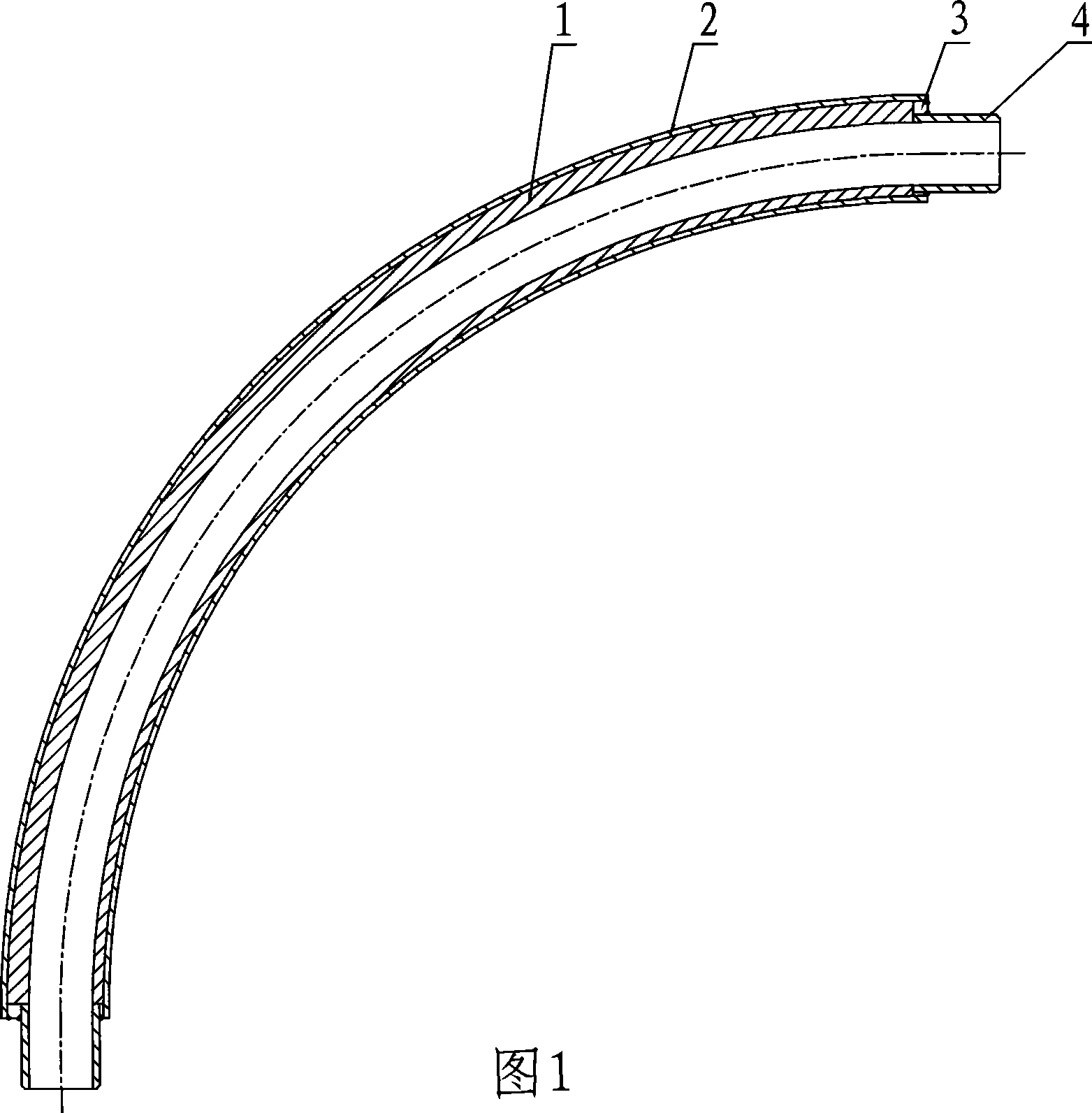

Duplex-metal abrasion-proof bent tube and producing method thereof

A production method and bimetal technology, applied in the direction of pipes, elbows, rigid pipes, etc., can solve the problems of inability to repair, increase the maintenance amount, labor intensity and production cost of workers, inconvenient installation, disassembly and maintenance, etc., and reduce labor. Strength and production cost, novel and unique production technology, high efficiency, energy saving and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Manufacture of metal elbows:

[0017] (1) According to the specific working conditions and fluid media of metal elbows, appropriate amount of nickel, molybdenum, vanadium, titanium, copper, rare earth and other alloys is added to control the chemical composition (content percentage) of the working surface at C2.0-3.0% , Si≤1.4%, Mn≤1.6%, Cr12.0~20.0%, Mo≤4.0%, Ni≤3.0%, Cu≤1.5%, P≤0.10%, S≤0.16%, V≤1.0%, Ti≤ 1.2% range; and use alloying and inoculation treatment process to pour into eccentric casting core tube through casting mold, that is, metal elbow.

[0018] (2) In order to ensure the hardness and wear resistance of the working surface of the metal elbow, the casting is quenched (the maximum temperature is controlled at 980-1050°C), and then tempered at 250-350°C, HRC≥60.

[0019] (3) Clean and polish the casting risers, flashes, burrs, sticky sand, and succulents.

[0020] 2. Manufacture outsourced steel pipes:

[0021] The first step is to use the metal bent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com