Method for rapidly detecting biochemical oxygen demand by using on site culture organism

A technology of biochemical oxygen demand and on-site cultivation, which is applied in the field of on-site cultivation of microorganisms to detect biochemical oxygen demand, can solve the problems of limitation, preservation, short service life, and difficulty in activation, so as to prolong the service life, improve practicability, and practicality Apply promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

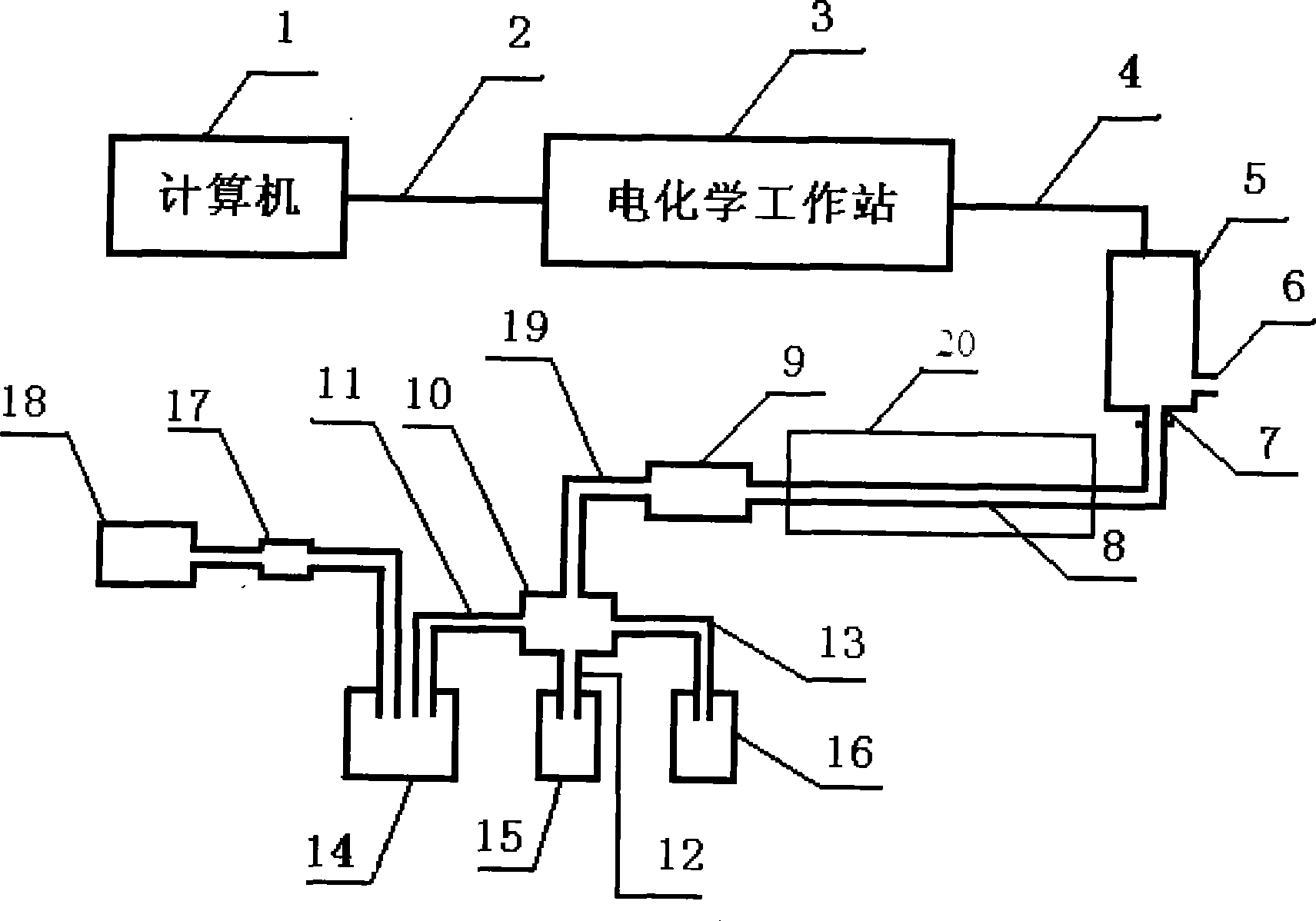

[0026] Example 1 Detection of milk factory water samples

[0027] The sample cup 14 is pre-filled with 300ml milk factory water sample, and it is air-saturated at a rate of 3L / min. The current-carrying tube 8 is a plastic tube with a length of 180 cm and a material of ethylene-vinyl acetate copolymer (EVA), with an inner diameter of 1.2 mm. The current-carrying tube 8 is placed in a constant temperature water bath with a temperature of 30°C. After the cultivation started, the peristaltic pump 9 delivered the water sample from the water sample cup 14 to the surface of the oxygen electrode 5 through the current-carrying tube 8 at a flow rate of 1.0ml / min. The flow rate of min is supplied to the water sample cup 14. After culturing for 48h, the BOD 5The 20.0mg / L GGA standard solution was injected into the standard solution cup 16, the 5mM phosphate buffer solution was injected into the buffer solution cup 15, and both were saturated with air at 3L / min. Change the flow directi...

Embodiment 2

[0029] Example 2 Detection of settled biochemical aeration tank water samples in urban sewage treatment plants

[0030] The water sample cup 14 is pre-filled with 300ml of settled biochemical aeration tank water samples from urban sewage treatment plants, and is saturated with air at a rate of 3L / min. The current-carrying tube 8 is a glass tube with a length of 120 cm and an inner diameter of 1.6 mm. First, the inner wall of the carrier tube 8 is covered with HF / NH 4 The F solution (1.7%:2.3%, w:w) corrodes and roughens it. The current-carrying tube 8 is placed in a constant temperature water bath with a temperature of 37°C. After the cultivation started, the peristaltic pump 9 delivered the water sample from the water sample cup 14 to the surface of the oxygen electrode 5 through the current-carrying tube 8 at a flow rate of 0.5ml / min. The flow rate of min is supplied to the water sample cup 14. 24 hours after the on-site culture was established, the BOD 5 The 5.0mg / L GG...

Embodiment 3

[0032] Embodiment 3 detects the water sample of the sewage treatment plant through primary sedimentation and coarse filtration

[0033] The water sample cup 14 is pre-filled with 300ml of water samples from the sewage treatment plant that have undergone primary sedimentation and coarse filtration, and are saturated with air at a rate of 3L / min. The current-carrying tube 8 is a glass tube with a length of 120 cm and an inner diameter of 1.6 mm. First, the inner wall of the carrier tube 8 is covered with HF / NH 4 The F solution (1.7%:2.3%, w:w) corrodes and roughens it. Inject 1M NaOH into the cleaned glass tube and continuously sonicate for 30 min, then fully wash with deionized water. 2 mg of carboxylated multi-walled carbon nanotubes (MWNTs) were dissolved in 10 ml of 1.0 mg / mL polydiallyldimethylammonium chloride (PDDA) and 0.5 M NaCl aqueous solution and sonicated for 3 hours. After centrifugation at 15000rpm for 10min, the MWNTs-PDDA complex was collected and fully washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com