Double-inclined transducer

A transducer and chip technology, applied in the field of ultrasonic probes, can solve the problems of poor signal-to-noise ratio, poor contact reliability, low sensitivity, etc., and achieve the effects of small change in K value, improved reliability, and strong signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

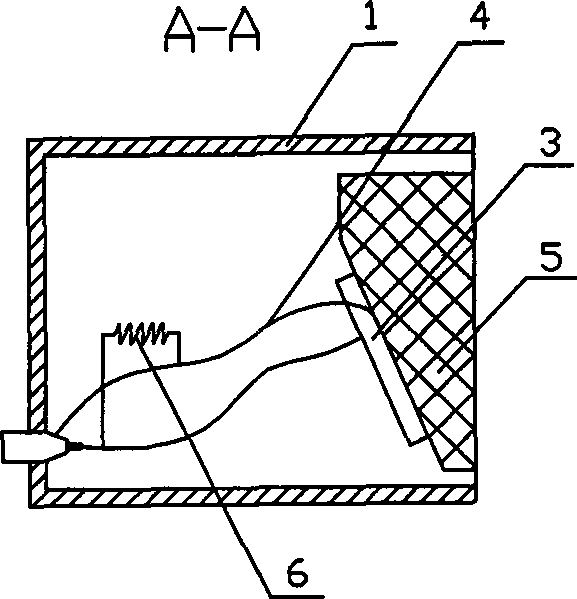

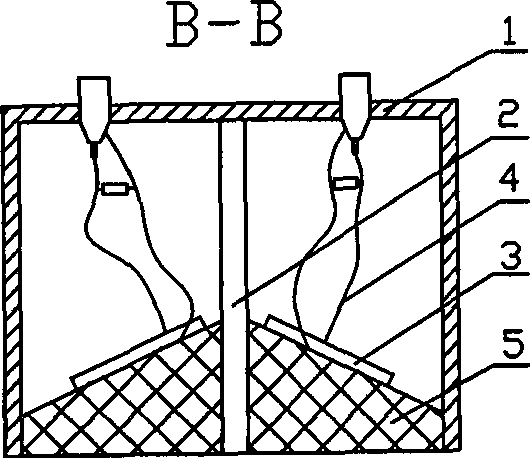

[0016] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

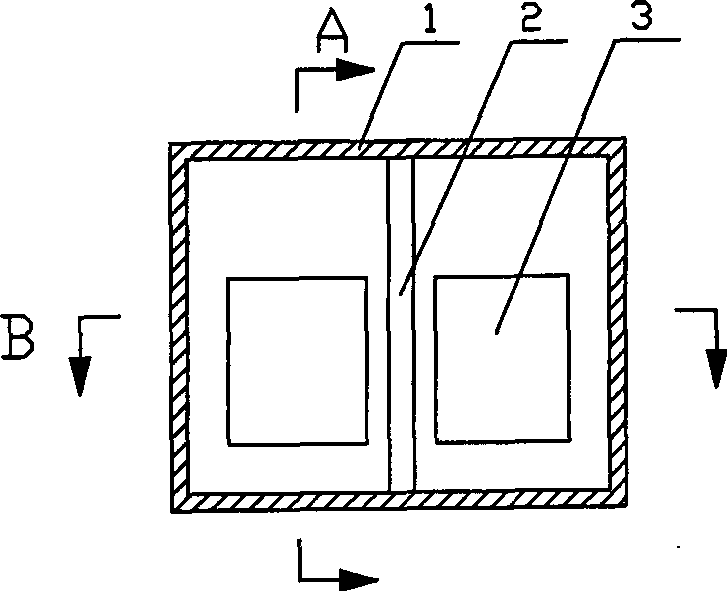

[0017] Such as figure 1 , figure 2 , image 3 The bislant transducer shown has a hollow shell 1 with one end open, a wedge 5 is arranged at the open end of the shell 1, and at least two wafers 3 are arranged in the shell 1, and the front and back of the wafer 3 are connected with wires 4 and wires respectively. 4 connected to the socket, the two chips 3 are composed of a transmitting chip and a receiving chip, the transmitting chip, the receiving chip and the opening end face of the shell 1 form an incident angle, the transmitting chip and the receiving chip have a deflection angle, and there is a gap between the transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com