Low melting point nylon 6 and preparation method thereof

A low melting point, nylon technology, applied in the field of low melting point nylon 6 and its melt extrusion modification, can solve the problems of complex process, difficult industrialization, high production cost, and achieve simple method, low production cost and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

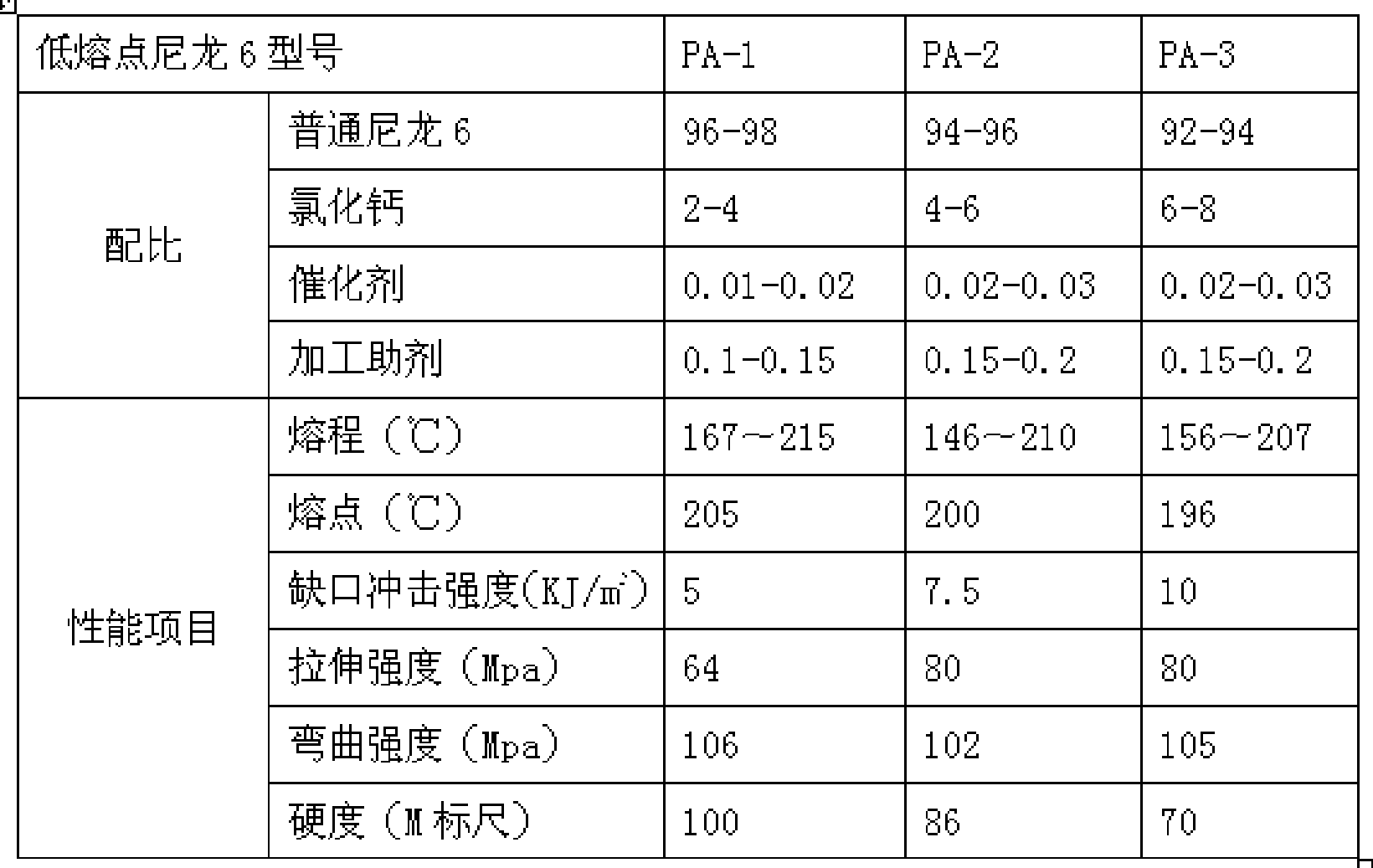

[0013] The preferred embodiment of the present invention: calcium chloride is dried in a vacuum dryer at 120 ° C for 10 hours, then pulverized and refined with a high-speed mixer, and weighed according to the weight ratio of ordinary nylon 695Kg, calcium chloride 5Kg, catalyst ferric chloride 0.03Kg and processing aid glycerol 0.15Kg, mix ordinary nylon 6 particles, calcium chloride, ferric chloride and glycerol uniformly, and extrude them in a twin-screw extruder according to the method of polymer processing and molding And granulation to obtain low-melting nylon 6, wherein the screw temperature of the twin-screw extruder is 200-270 DEG C, and the screw speed is 160-240 rpm. Within the scope of the above formula and process, the optimization process of different ratio systems is different. Table 1 shows the performance index of the typical low melting point nylon 6 obtained by the optimization process experiment.

[0014] Table 1 Performance index of typical low melting point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com