Micro-crack on site concrete strength detecting method and implementing device thereof

A concrete strength and detection method technology, which is applied in the construction industry, water conservancy engineering, and civil engineering fields, can solve the problems that cannot meet the requirements of aging concrete strength detection, the execution process is complicated, and the detection data is highly discrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0058] The invention discloses a concrete strength detection technology on the spot with minimal damage, and relates to an instrument for testing using the method.

[0059] The specific operation is as follows:

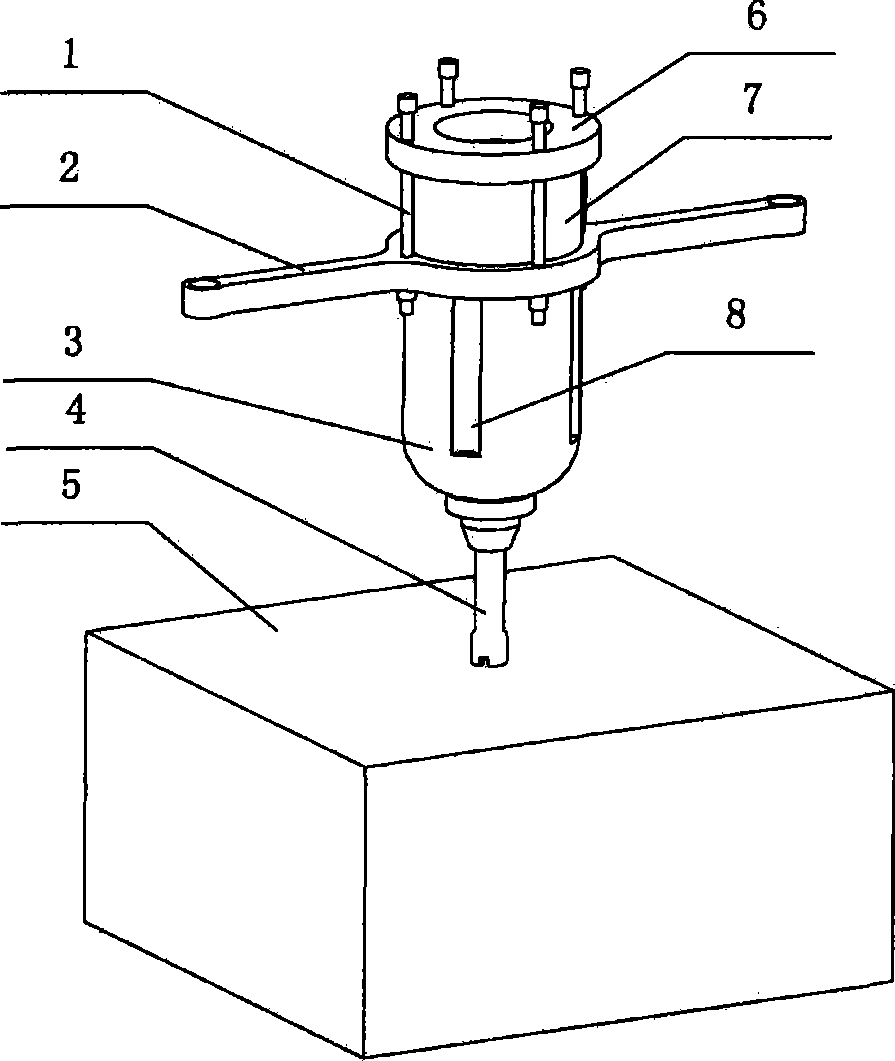

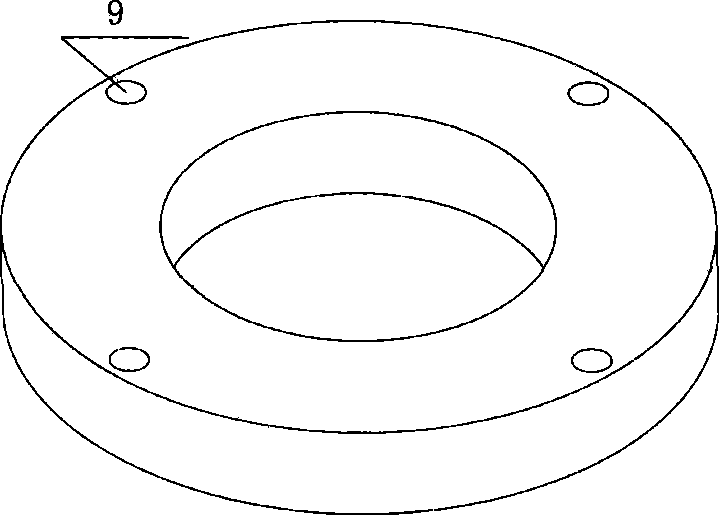

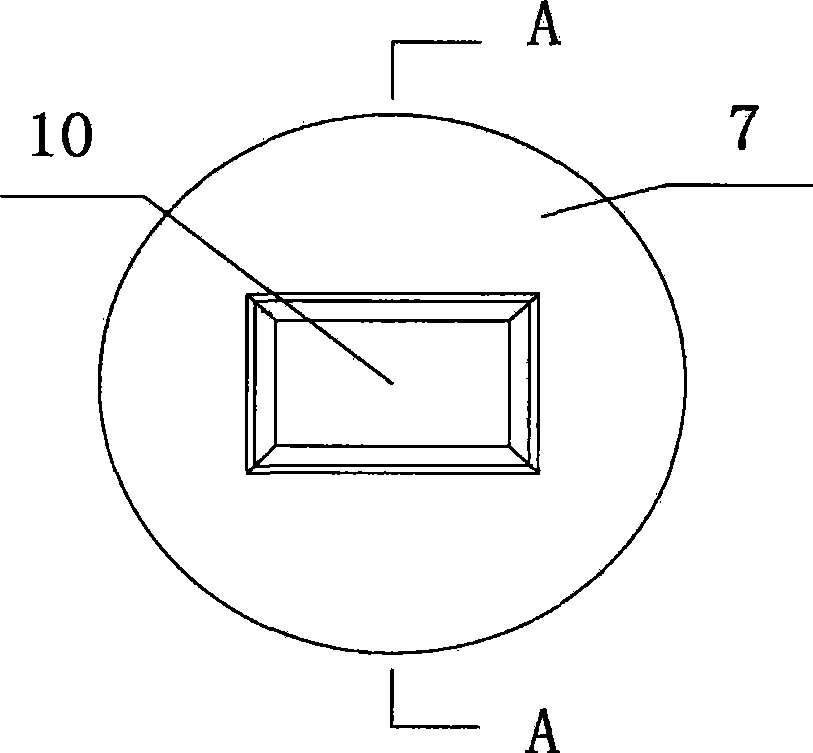

[0060] 1. Assemble the detection device. like Figure 1-Figure 4 As shown, the instrument mainly includes: a drilling rig 3 , a drill bit 4 , a force applying frame and an external force monitor 7 . The external force monitor 7 can be used as a fixed component, or temporarily assembled according to needs, and it is composed of four components: a pressure sensor 11 , a data collector 13 , a liquid crystal display 10 and an external protection device 12 . The pressure sensor 11 is used to monitor the external force acting on the drilling rig; the data collector 13 collects the pressure sensor signal, converts it into pressure, display...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com