Resource treatment method of clear-water basin

A treatment method and technology of purifying pool, applied in the direction of sludge treatment through temperature control, etc., can solve the problems of pollution, silt deposition environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

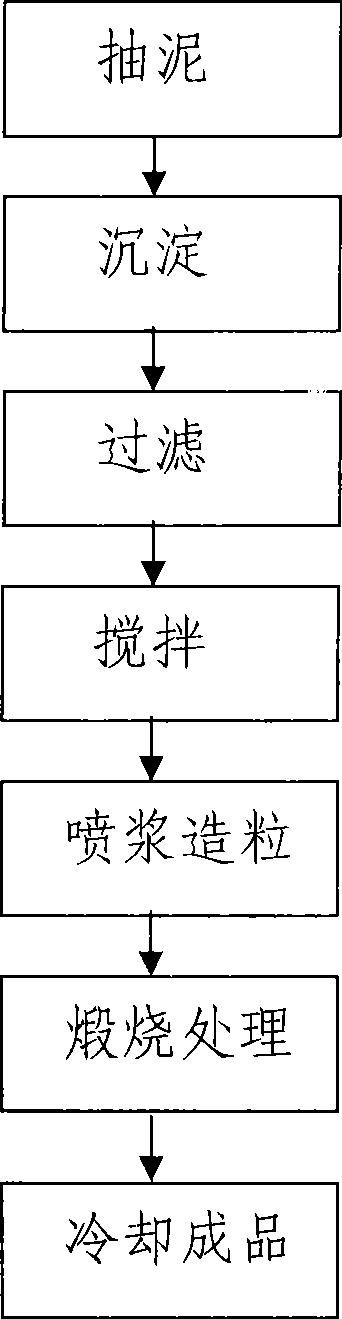

[0008] see figure 1 The flow chart of the implementation steps of the present invention, by figure 1 It can be seen that the method for resourceful treatment of water purification tank sludge of the present invention comprises the steps of:

[0009] Sludge pumping: the bottom sludge is extracted from the clean water tank and pumped to the sludge sedimentation tank;

[0010] Sedimentation: The clarified water is drained in a multi-tank alternate manner, and then the sludge is introduced until the sedimentation tank is full of thick sludge;

[0011] Filtration: filter the sludge to remove impurities;

[0012] Stirring: Stir the sludge after filtering out impurities with a strong stirring pump and cause reflux, so that the sludge no longer settles;

[0013] Shotcrete granulation: The mud is pressurized by a high-pressure pump, sent to the granulation nozzle, and sprayed into the high-temperature sterilization drying tower. The hot air with high-speed heat flow in the tower is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com