Gypsum insulation plate and connection method thereof with major structure of construction

A connection method and technology of building main body, applied in the direction of building structure, construction, covering/lining, etc., can solve problems such as low degree of standardization, large temperature difference and absolute humidity difference, complicated installation process, etc., and achieve high degree of componentization, Fast installation speed and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

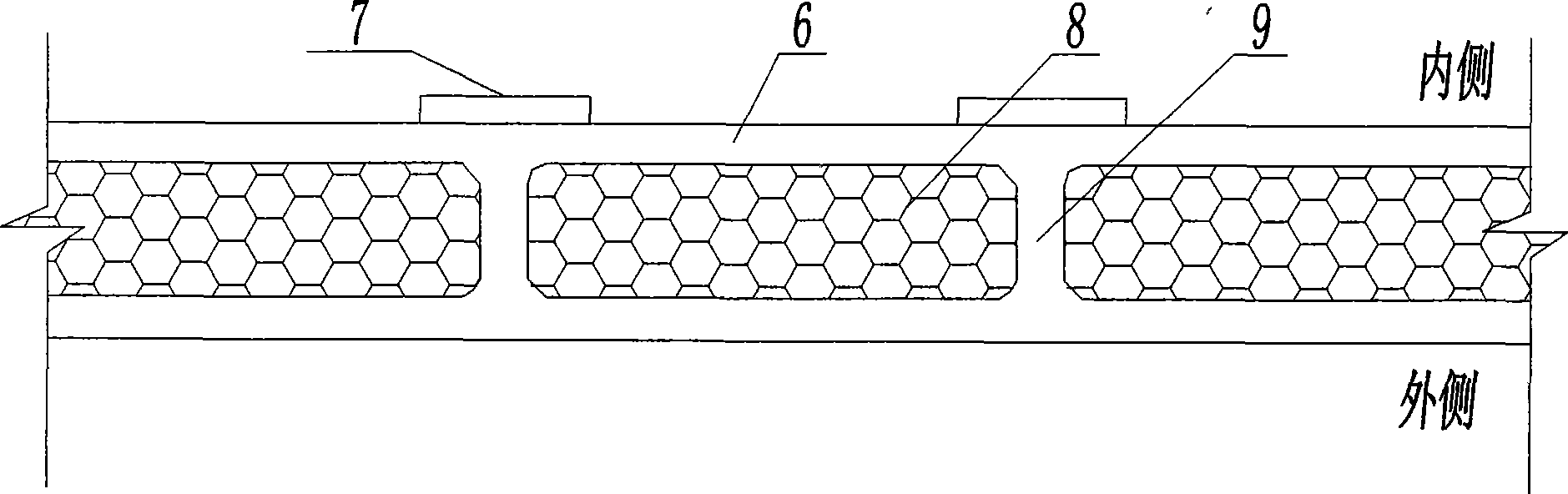

[0038] ②. If Figure 6 , Figure 7 , Figure 8 , Figure 9 Shown: The connection method of the single-cavity gypsum insulation board used for internal insulation of the main body of the building. It is composed of a single-cavity gypsum insulation board and a brick-concrete wall. The number of single-cavity gypsum insulation boards 6 is increased or decreased according to the internal insulation requirements, such as Figure 8 When the internal insulation requirements cannot be met, use Figure 9 In the form of single-chamber gypsum insulation board 6 inner side keel 7 and brick wall 23, coat one layer of adhesive or adopt expansion tube to fix. Embodiment 1: A connection structure in which the exterior wall of a building is connected with a double-cavity gypsum insulation board 1 by using an overhanging concrete member

[0039] as an example

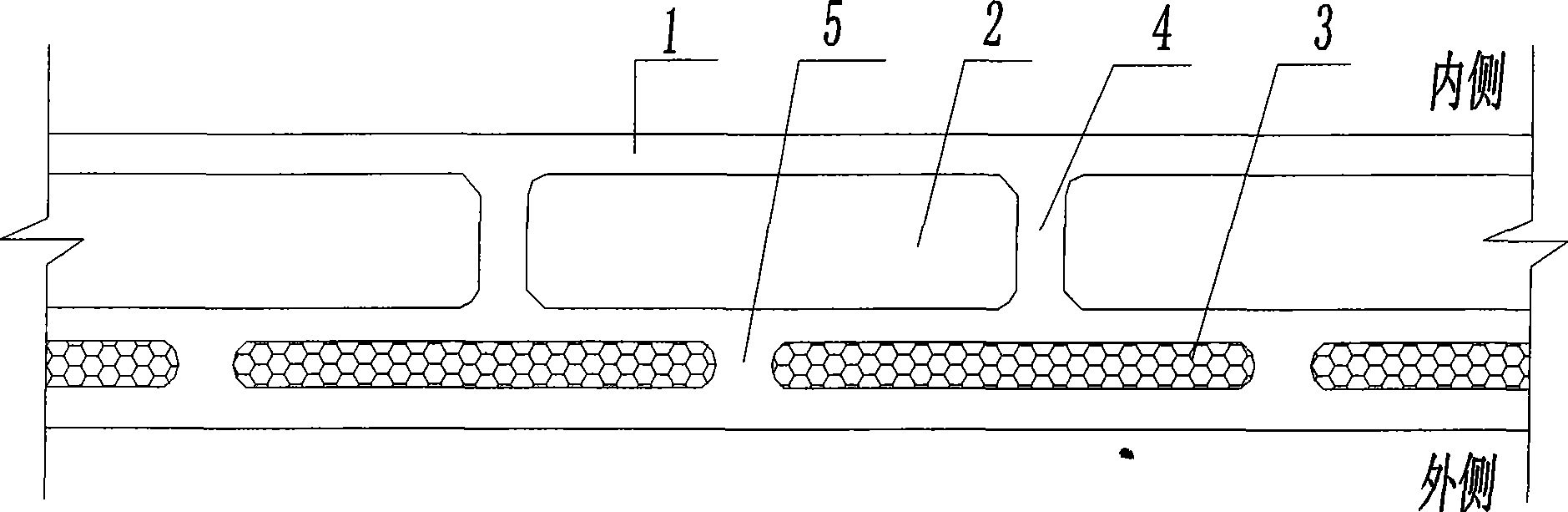

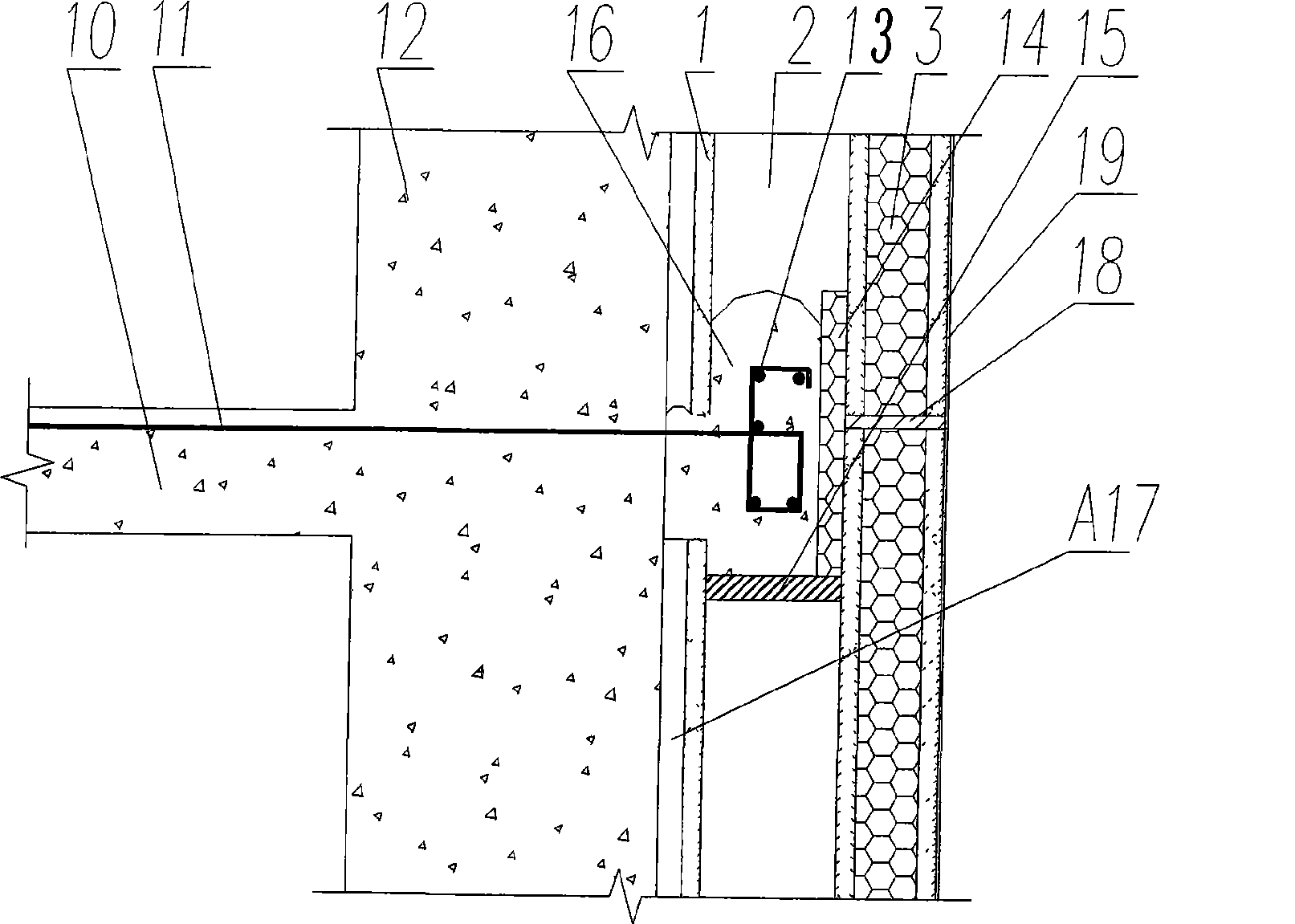

[0040] Such as image 3 , Figure 4 Shown: when the external concrete member is used, the main structural form of the shear wal...

Embodiment 2

[0042] Example 2: Taking the connection structure between the embedded steel parts in the building exterior wall and the double-cavity gypsum insulation board 1 as an example

[0043] Such as Figure 5 Shown: When pre-embedding steel components, pre-embed steel components 20 in the shear wall 12, fix B steel plates 21 on the double-cavity gypsum insulation board 1 corresponding to the pre-embedded steel components 20 and weld them, There is a B gap 22 between the insulation board 1 and the shear wall 12 to form an air cavity to increase heat preservation and sound insulation effects, and a layer of exterior wall paint 19 is also coated outside the double-chamber gypsum insulation board 1 .

[0044] Its advantage is identical with embodiment 1.

Embodiment 3

[0045] Example 3: Take the connection method of single-cavity gypsum insulation board for building thermal insulation as an example

[0046] Such as Figure 9 Shown: The single-cavity gypsum insulation board is used for the connection structure of the main body of the building for thermal insulation. It is composed of a single-cavity gypsum insulation board and a brick-concrete wall. The cavity gypsum insulation board 6 is connected to the keel 7 inside the single cavity gypsum insulation board 6 and the brick wall 23 through an adhesive (or an expansion tube connection).

[0047] Its advantage is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com