Long-persistence phosphor with ultra-fine grain diameter and high light effect, and method of producing the same

A long afterglow phosphor and ultra-fine particle technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult ultra-fine high-brightness phosphors to achieve breakthroughs, and achieve afterglow time guarantee, production cost reduction, powder fine particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

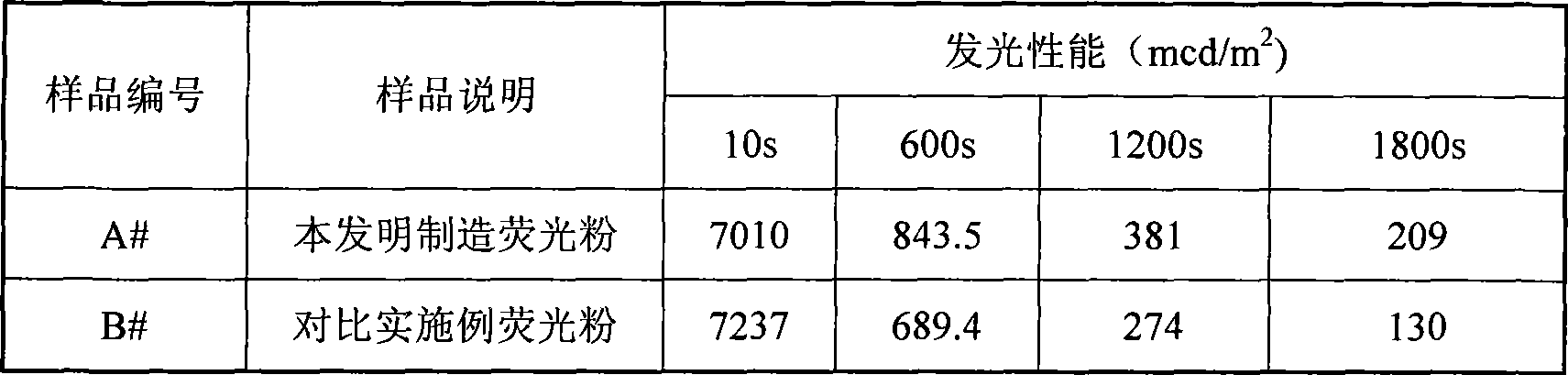

[0038] The chemical composition formula of the target product: Sr 0.93 Mg 0.12 Al 2 o 4.112 :Eu 0.022 , Dy 0.035 , Gd 0.005 As a basis for measurement, take the corresponding weight of SrCO 3 27.34g, Al 2 o 3 20.2g, MgO 0.96g, Eu 2 o 3 0.77g, Dy 2 o 3 1.31g, Gd 2 o 3 0.18g, H 3 BO 3 1.27g, 1.78g. After mixing, put it in a high-temperature reducing atmosphere furnace, under N 2 / H 2 Under the protection of mixed gas, the temperature was raised to 1330°C at a heating rate of 350°C / h, and then kept for 3 hours, then cooled to room temperature at a cooling rate of 120°C / h, and then released from the furnace. After pulverizing the burned phosphor powder, enter the jet mill and classifier for pulverization to obtain ultra-fine long-lasting phosphor. The central particle size d50 of the powder is 3-8 μm, d10 ≥ 1 μm, and d90 ≤ 12 μm.

[0039] Take the crushed long-lasting phosphor powder and add it to the prepared aluminum nitrate solution with a mass percen...

Embodiment 2

[0041] The chemical composition formula of the target product: Sr 0.94 Mg 0.21 Al 2 o 4.192 :Eu 0.012 , Dy 0.025 , La 0.0046 As a basis for measurement, take the corresponding weight of SrCO 3 27.64g, Al 2 o 3 20.2g, MgO 1.68g, Eu 2 o 3 0.42g, Dy 2 o 3 0.93g, La 2 o 3 0.15g, H 3 BO 3 0.51g, NH 4 F 0.18g. After mixing, put it in a high-temperature reducing atmosphere furnace, under N 2 / H 2 Under the protection of mixed gas, the temperature was raised to 1380°C at a heating rate of 415°C / h, and then kept for 5 hours, then cooled to room temperature at a cooling rate of 110°C / h, and then released from the furnace. After pulverizing the burned phosphor powder, enter the jet mill and classifier for pulverization to obtain ultra-fine long-lasting phosphor. The central particle size d50 of the powder is 3-8 μm, d10 ≥ 1 μm, and d90 ≤ 12 μm.

[0042] Take the crushed long afterglow phosphor powder and add it into the prepared post-treatment solution with a mas...

Embodiment 3

[0044] The chemical composition formula of the target product: Sr 1.2 Mg 0.08 Al 2 o 4.334 :Eu 0.016 , Dy 0.028 , La 0.01 As a basis for measurement, take the corresponding weight of SrCO 3 33.92g, MgO 0.62g, Al 2 o 3 19.42g, Eu 2 o 3 0.54g, Dy 2 o 3 1.00g, La 2 o 3 0.31g, H 3 BO 3 0.84g, NH 4 F 0.25g. After mixing, put it in a high-temperature reducing atmosphere furnace, under N 2 / H 2 Under the protection of mixed gas, the temperature was raised to 1450°C at a heating rate of 375°C / h, and then kept for 4.5 hours, then cooled to room temperature at a cooling rate of 110°C / h, and then released from the furnace. After pulverizing the burned phosphor powder, enter the jet mill and classifier for pulverization to obtain ultra-fine long-lasting phosphor. The central particle size d50 of the powder is 3-8 μm, d10 ≥ 1 μm, and d90 ≤ 12 μm.

[0045] Take the crushed long afterglow phosphor powder and add it into the prepared post-treatment solution with a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com