Production method of surface sizing agent, sizing agent and use thereof

A technology of surface sizing agent and sizing agent, which is applied in papermaking, water repellent addition, textiles and papermaking, etc. It can solve the problems of stiffness and insufficient surface strength and water resistance of cardboard, and achieve quality Stability, low preparation cost, and the effect of improving product quality and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

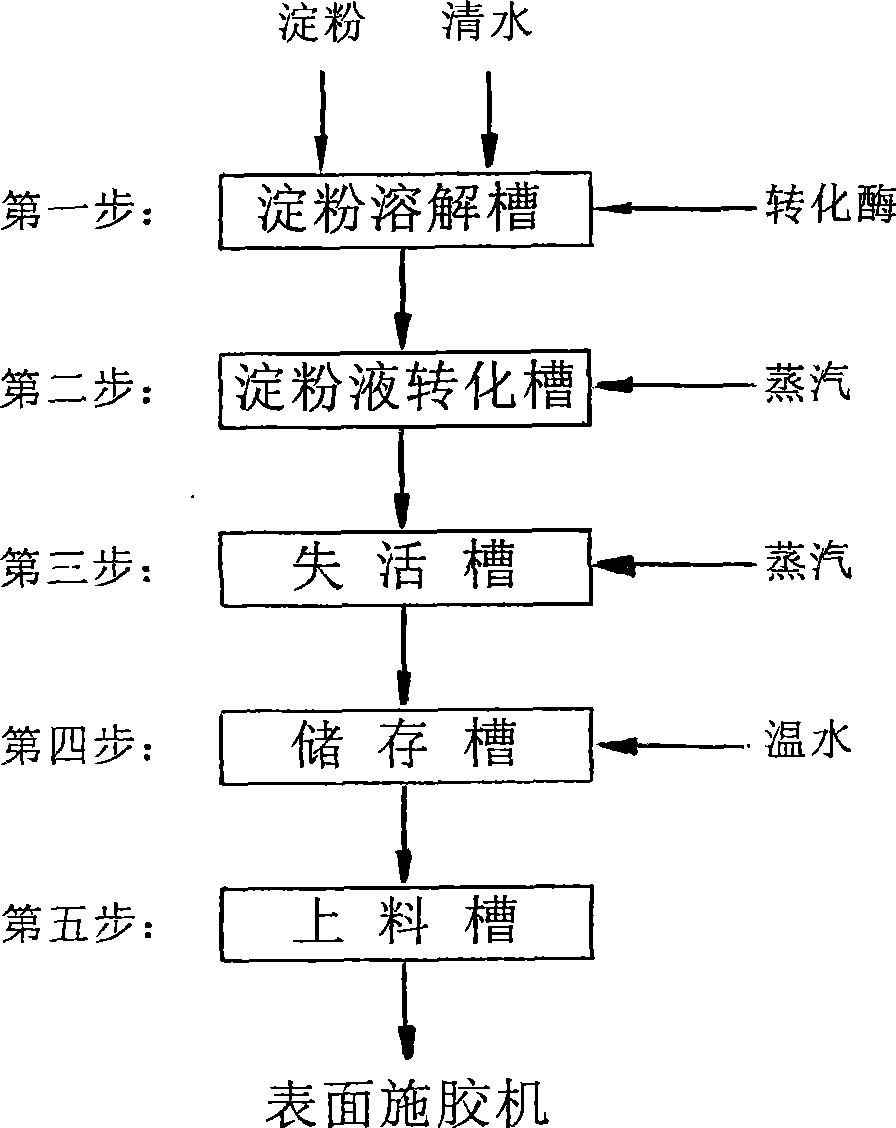

[0013] A kind of starch surface sizing agent manufacture method, see figure 1 , using starch as a raw material, and the starch can be any of tapioca starch, corn starch, potato starch and the like. The process steps are: 1. Dissolution of starch: the starch is transported to the dissolution tank through a screw conveying device with metering function, and 30-40 ° C water is added in proportion to the dissolution tank to dilute to a concentration of about 25%. Add invertase in the amount of 0.2-0.4KG / ton of starch. 2. Starch conversion: The diluted starch slurry is transported to the conversion tank, and steam is introduced into the tank body. The steam is added from the bottom of the tank body through a steam adding device with a Venturi structure, which can ensure that the overall tank The starch slurry in the body is heated quickly and evenly, and the noise caused by adding steam can be avoided. In order to achieve the ideal conversion effect, a vertical stirrer is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com