High-pressure earth mortar pile squeezing method and system

A high-pressure, soil-sand technology, applied in sheet pile walls, sequence/logic controller program control, electrical program control, etc., can solve the problems of precipitation affecting the surrounding area, insignificant effect, and high environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0052] Mortar material composition: cement, yellow sand, coal ash, admixture, water, the ratio is 1:6:1.5:0.02:1 (admixture can be added according to soil properties and depth, generally can be ignored, and small particles can be added for special needs Stones form fine stone concrete, and the strength can be adjusted to be higher).

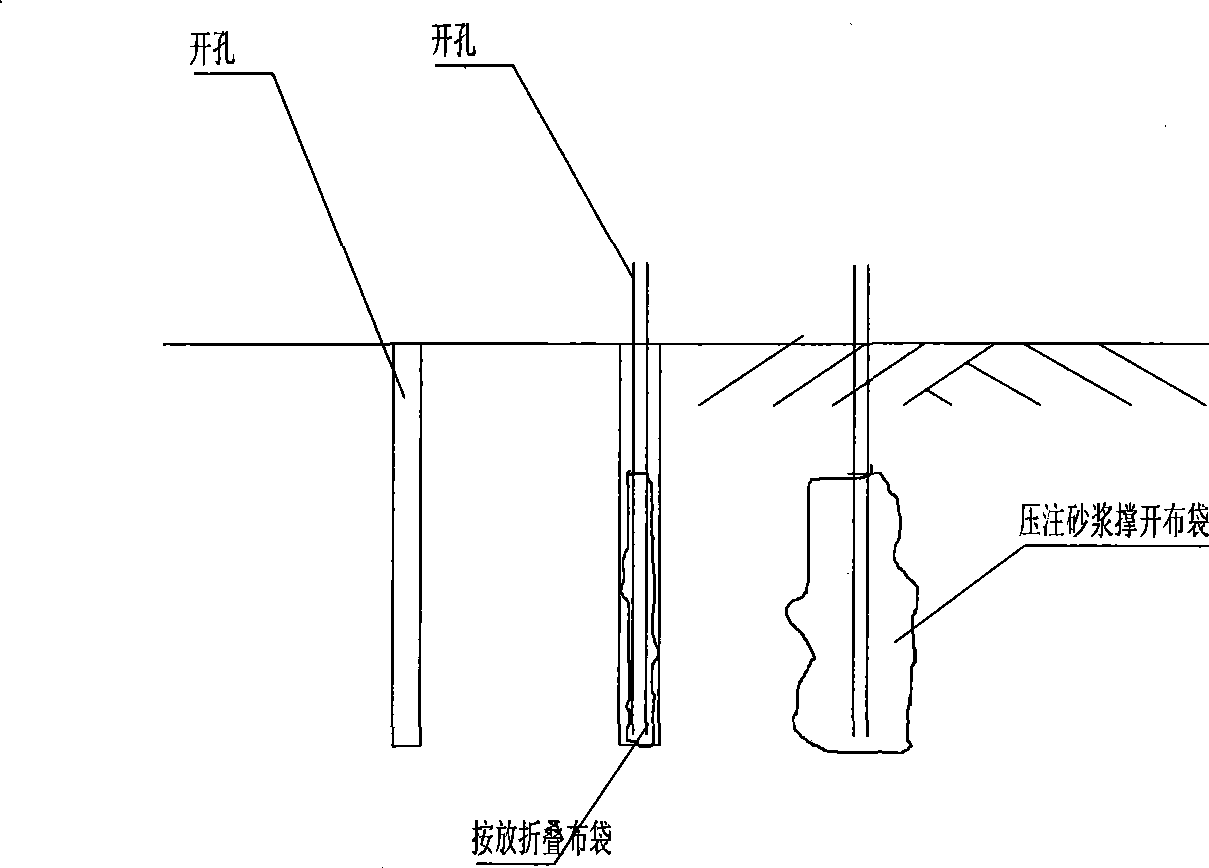

[0053] Physical characteristics: The material of the slurry is plastic, 80% of the mortar is sand, and the mortar is a mixture of low viscosity, low consistency and good bleeding.

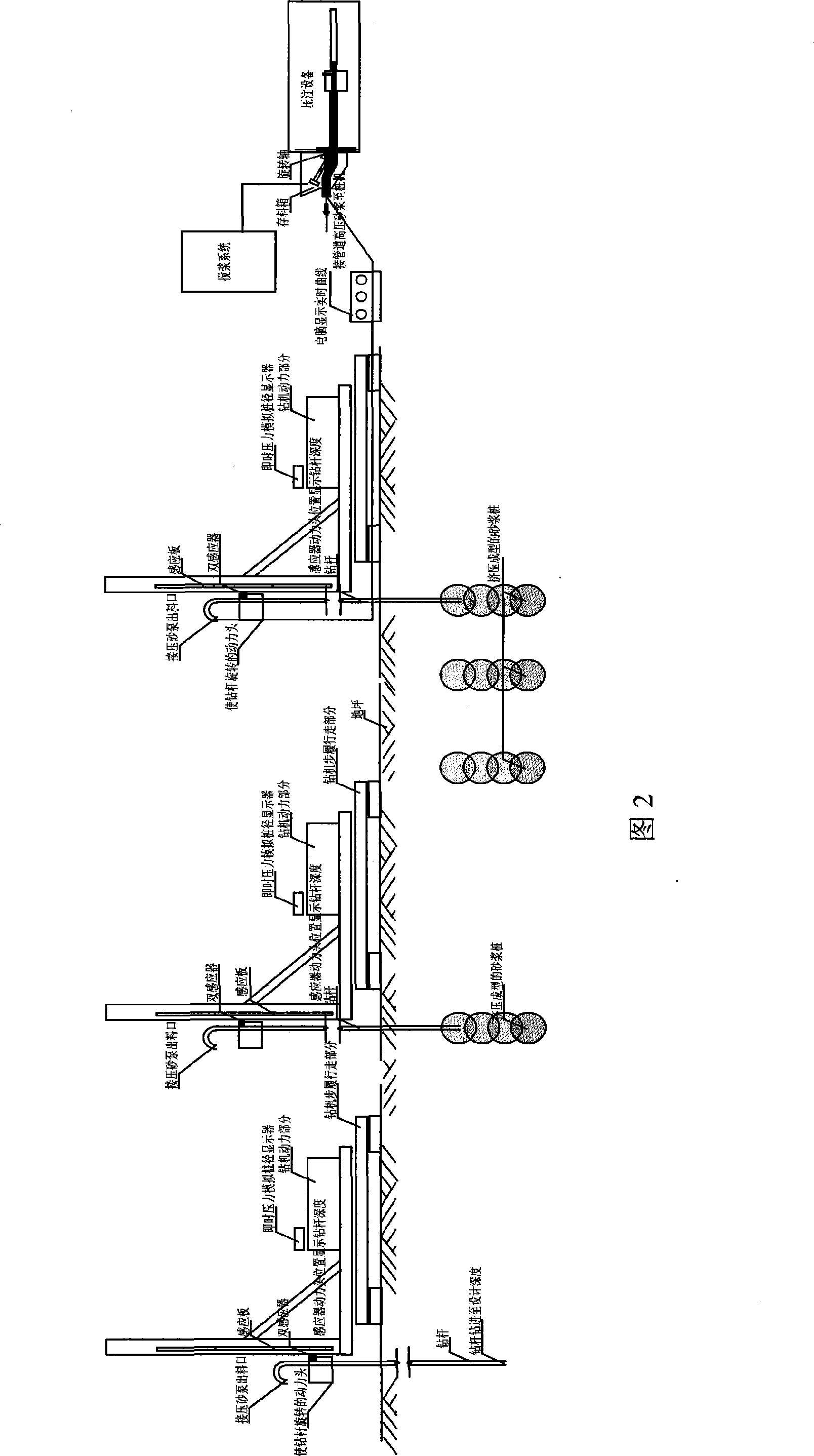

[0054] Equipment: In order to overcome the problem of mortar bleeding, a mixing system is added to the injection pump. The injection equipment is double-cylinder continuous injection, and the pressure and flow are reasonably matched. The injection pipe adopts variable diameter sealing.

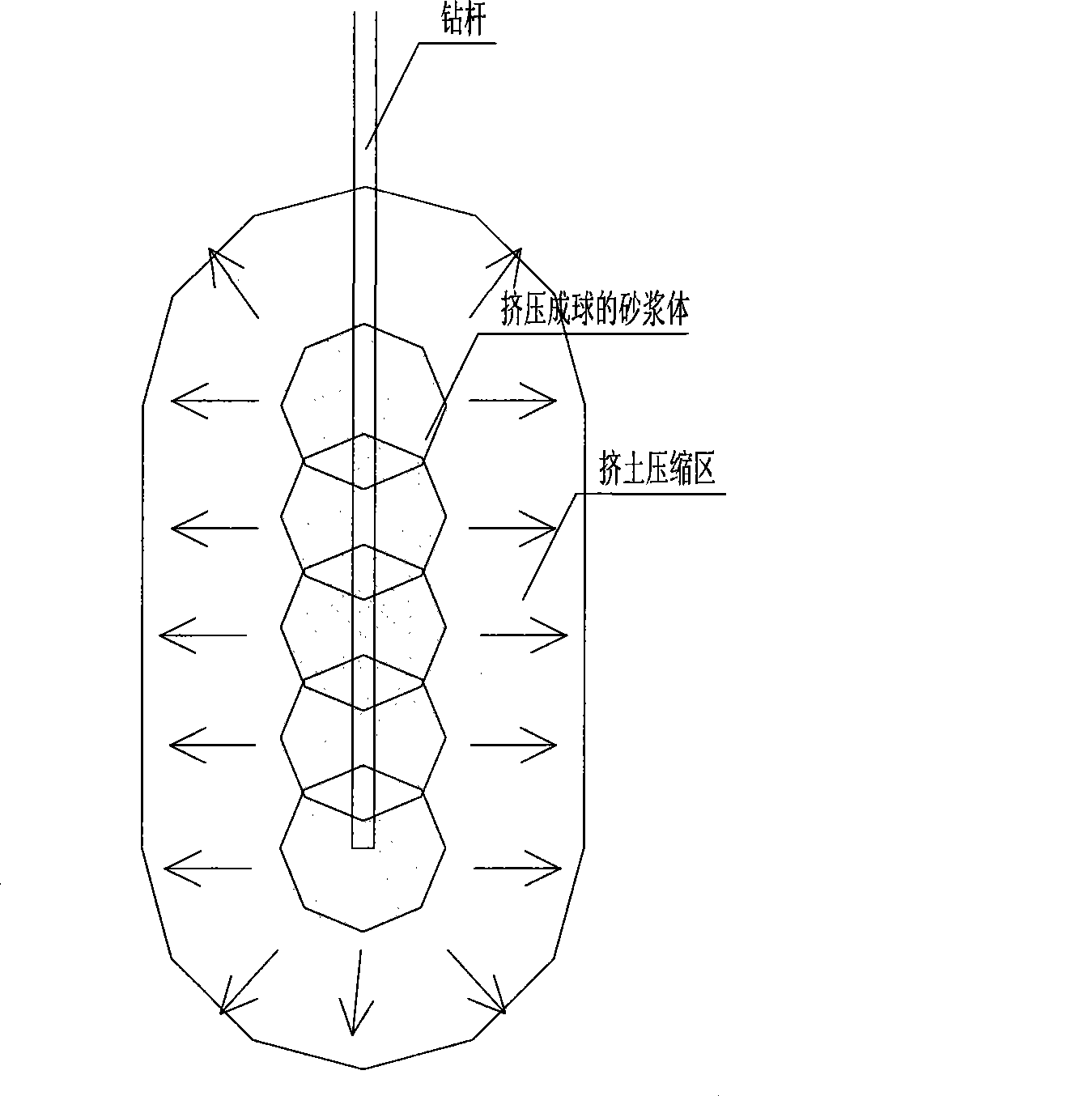

[0055] Process features: The slurry material ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com