Aluminum doped titanium dioxide nano tube visible-light responsive photocatalyst and preparation method

A titanium dioxide and nanotube technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high processing cost, achieve the effect of reducing processing cost and improving visible light excitation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

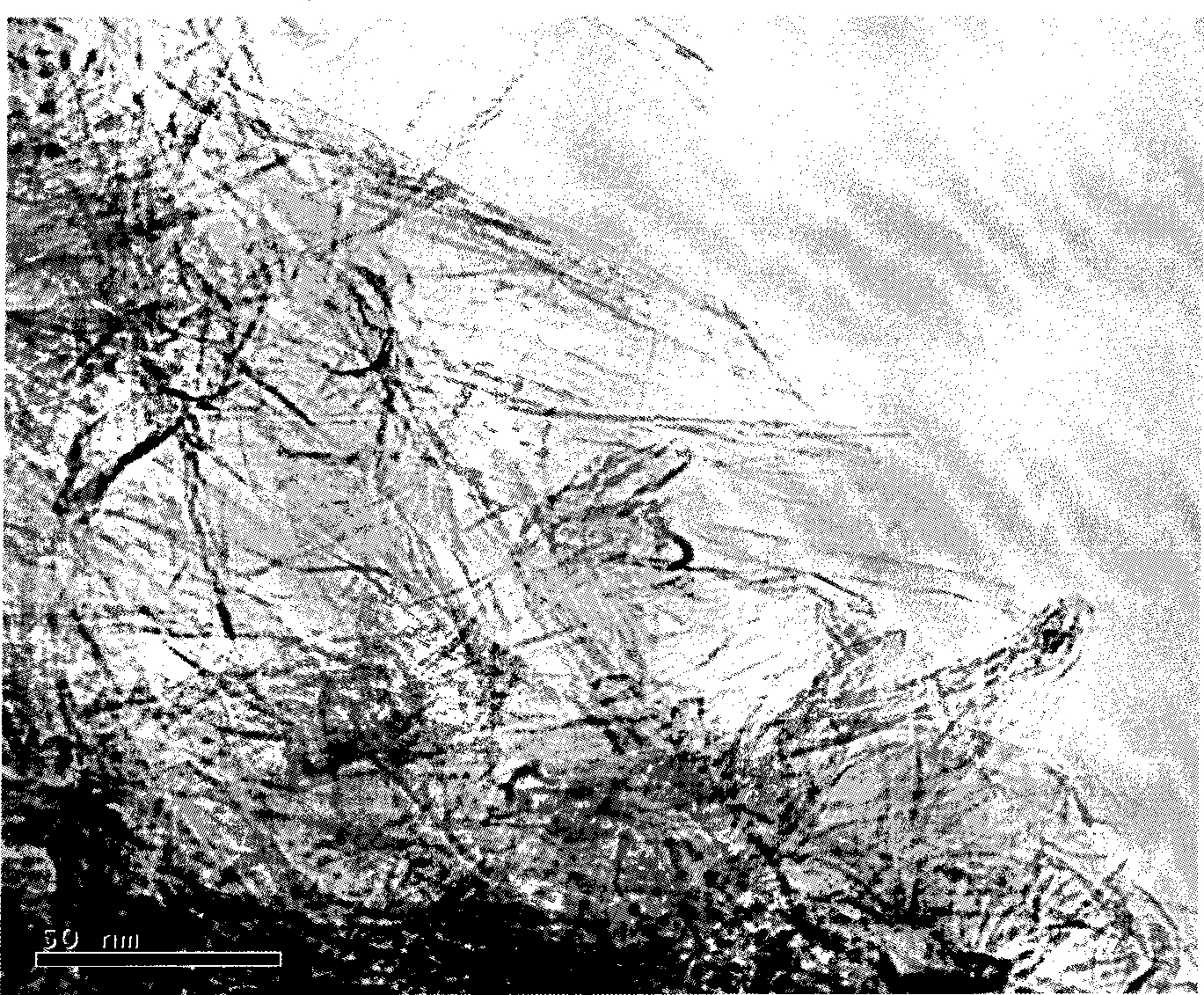

Image

Examples

Embodiment 1

[0026] A method for preparing an aluminum-doped titanium dioxide nanotube visible light catalyst, comprising the steps of:

[0027] (1) Add 0.7g of titanium dioxide powder and 0.10g of aluminum oxide powder to 17mL of 10mol / L aqueous sodium hydroxide solution, stir for 0.8h; transfer to a reaction kettle lined with polytetrafluoroethylene, and heat to 110°C , react for 25h;

[0028] (2) cooling to normal temperature, washing the product with water until the pH is 7;

[0029] (3) Use 0.1mol / L hydrochloric acid aqueous solution to adjust the pH of the solution obtained in step (2) to be 2, soak for 0.5h, and then wash with water until the pH is 7;

[0030] (4) Filter the solution prepared in step (3), and dry the intercepted concentrated solution at 60° C. under normal pressure for 6 hours to obtain a solid;

[0031] (5) Calcining the solid described in step (4) at 500° C. for 6 hours to produce an aluminum-doped titania nanotube visible light catalyst.

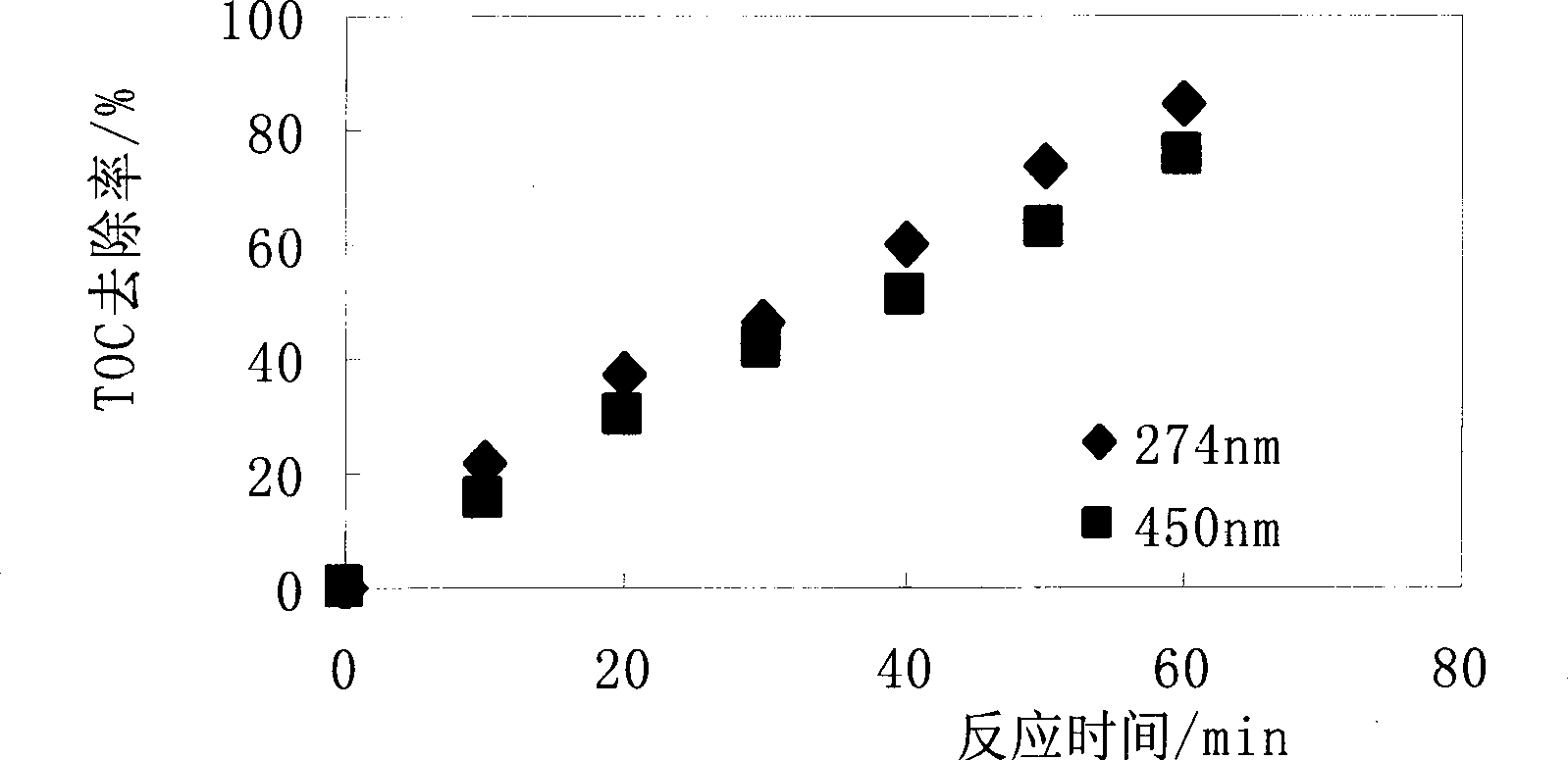

[0032] In this examp...

Embodiment 2

[0035] An aluminum-doped titanium dioxide nanotube visible light catalyst is made by the following method:

[0036] (1) Add 1.0g of titanium dioxide powder and 0.30g of aluminum oxide powder to 15mL of 10mol / L potassium hydroxide aqueous solution, stir for 0.5h; heat to 120°C, and react for 20h;

[0037] (2) cooling to normal temperature, washing the product with water until the pH is 7.5;

[0038] (3) Use 0.5mol / L sulfuric acid aqueous solution to adjust the pH of the solution obtained in step (2) to be 3, soak for 1h, and then wash with water until the pH is 7.5;

[0039] (4) Filter the solution prepared in step (3), and dry the intercepted concentrated solution at 70° C. under normal pressure for 5 hours to obtain a solid;

[0040] (5) Calcining the solid described in step (4) at 400° C. for 6 hours to produce an aluminum-doped titania nanotube visible light catalyst.

Embodiment 3

[0042] An aluminum-doped titanium dioxide nanotube visible light catalyst is made by the following method:

[0043] (1) Add 0.5g of titanium dioxide powder and 0.20g of aluminum oxide powder to 20mL of 10mol / L potassium hydroxide aqueous solution, stir for 0.8h; heat to 100°C, and react for 30h;

[0044] (2) cooling to normal temperature, washing the product with water until the pH is 6.5;

[0045] (3) Use 0.3mol / L phosphoric acid aqueous solution to adjust the pH of the solution obtained in step (2) to 1, soak for 0.4h, and then wash with water until the pH is 6.5;

[0046] (4) Filter the solution prepared in step (3), and dry the intercepted concentrated solution at 50° C. under normal pressure for 7 hours to obtain a solid;

[0047] (5) Calcining the solid described in step (4) at 700° C. for 5 hours to produce an aluminum-doped titania nanotube visible light catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com