Method for preparing ZnS mischcrystal photocatalyst

A photocatalyst and solid solution technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problems of low hydrogen production rate, achieve low cost, high utilization efficiency of visible light, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

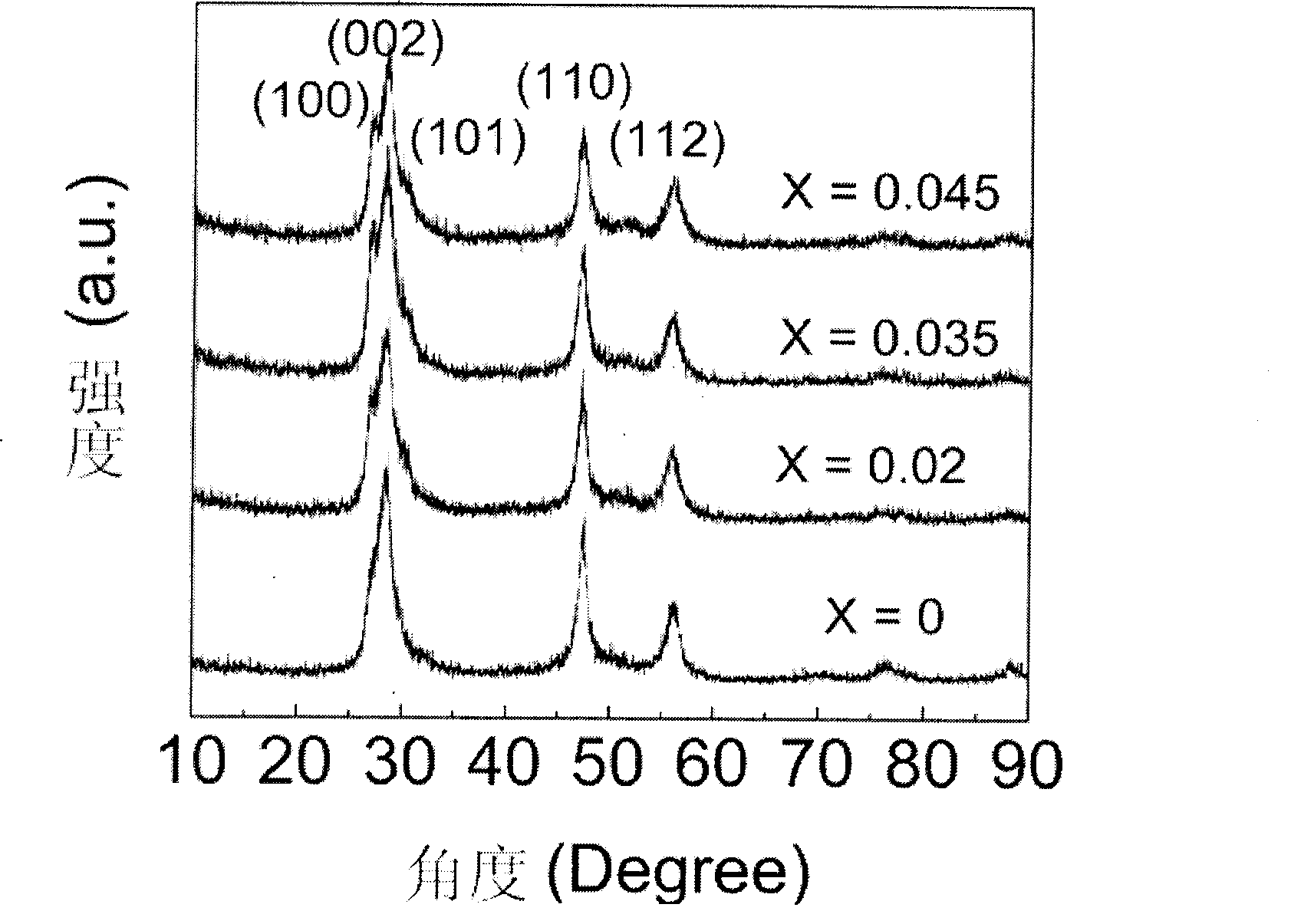

[0008] Specific embodiment one: the preparation method of the ZnS solid solution photocatalyst of the present embodiment is realized according to the following steps: one, the Zn(AC) of 0.8~2.1mmol 2 2H 2 O and 0.1 to 0.7 mmol of the third main group compound were added to 20 to 30 mL of pyridine, and stirred for 1 to 2 hours; 2. Add 5.4 to 32.4 mmol of thioacetamide to the mixed solution prepared in step 1, and then stirred for 10 to 30min; 3. Under stirring conditions, add 0.3-4.8mL transition metal salt pyridine solution with a molar concentration of 0.04mol / L dropwise to the mixed solution prepared in step 2; 4. Pour the mixed solution prepared in step 3 into the reaction kettle , react at 120-240°C for 8-48h, then cool to room temperature, wash with absolute ethanol for 3-5 times, and then dry at 50°C for 0.5-3h to obtain a ZnS solid solution photocatalyst; The three main group compounds are InCl 3 4H 2 O or GaCl 3 ; The transition metal salt in step three is AgNO 3 ...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the stirring time in Step 1 is 1 h. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the stirring time in Step 1 is 2 hours. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com