Preparation method of a silver silicate/attapulgite composite catalyst responsive to visible light

A technology of attapulgite and silver silicate, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of low utilization efficiency of visible light, lack of visible light catalytic performance, and reduced catalytic efficiency. Achieve the effects of improving the utilization efficiency of visible light, improving the utilization rate of sunlight, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

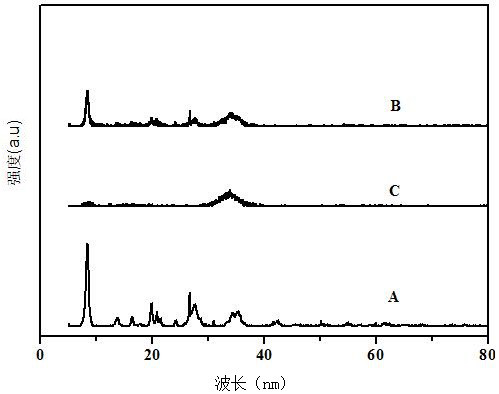

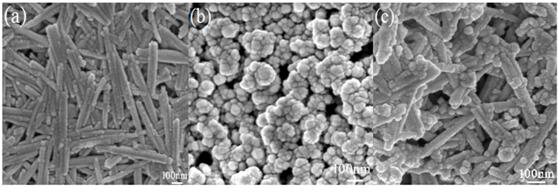

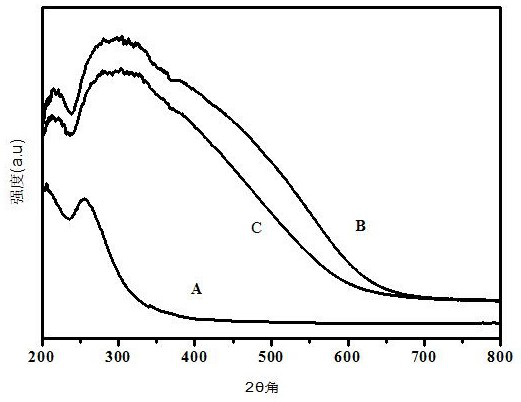

Embodiment 1

[0034] Weigh 10 g of attapulgite, add 100 ml of 1mol / L hydrochloric acid, ultrasonicate at 50°C for 12 h, filter, wash until neutral, and dry to obtain acidified attapulgite; then use 100 ml of 1mol / L sodium hydroxide , sonicate at 50°C for 12 h, filter, wash until neutral, and dry; finally, under nitrogen atmosphere, bake at 400°C for 1 h, cool to room temperature, and obtain modified attapulgite;

[0035] Weigh 1.0g of modified attapulgite, dissolve it in 100 mL of pure water, and ultrasonically disperse to form a uniform suspension, add 0.1275g of silver nitrate, and fully stir for ion adsorption in the dark for 4 hours to obtain a mixed solution;

[0036] Weigh 0.107g of sodium silicate, dissolve it in 70 ml of pure water, and sonicate for 0.5 h to obtain a uniform solution; then slowly add it dropwise to the above mixed solution at a pump speed of 30 mp; then stir at room temperature for 3 h, filter, and precipitate The material was washed with pure water and dried to obt...

Embodiment 2

[0038] Weigh 0.5 g of the modified attapulgite prepared in Example 1, dissolve it in 100 ml of pure water, and ultrasonically disperse to make a uniform suspension; add 0.255 g of silver nitrate, fully stir in the dark for ion exchange and Adsorbed for 8 h to obtain a mixed solution;

[0039] Weigh 0.142g of sodium silicate, dissolve it in 70 ml of pure water, ultrasonicate for 0.5 h to obtain a uniform solution, then slowly add it dropwise to the above mixed solution at a pump speed of 25 rpm, then stir at room temperature for 2 h, filter, The precipitate was washed with pure water and dried to obtain a silver silicate / attapulgite composite photocatalyst material, which was designated as ATP-ASO-2. The composite photocatalyst has a degradation rate of 73% for chloroform.

Embodiment 3

[0041] Weigh 1.0 g of the modified attapulgite prepared in Example 1, dissolve it in 100 ml of pure water, and ultrasonically disperse it to make a uniform suspension; add 0.51 g of silver nitrate, and fully stir in the dark for ion exchange and adsorption12 h, to obtain a mixed solution;

[0042] Weigh 0.284 g of sodium silicate, dissolve it in 70 ml of pure water, sonicate for 0.5 h to obtain a uniform solution, then slowly add it dropwise to the above mixed solution at a pump speed of 20 rpm, then stir at room temperature for 1 h, filter, and precipitate The material was washed with pure water and dried to obtain a silver silicate / attapulgite composite photocatalyst, which was designated as ATP-ASO-3. The composite photocatalyst material has a degradation rate of 92% for chloroform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com