Round billet continuous casting machine with especially big sectional plane

A round billet continuous casting and continuous casting machine technology, which is applied in the field of round billet/tube billet continuous casting equipment, can solve the problems of unsatisfactory output, quality and yield, and achieve energy saving, novel structure and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

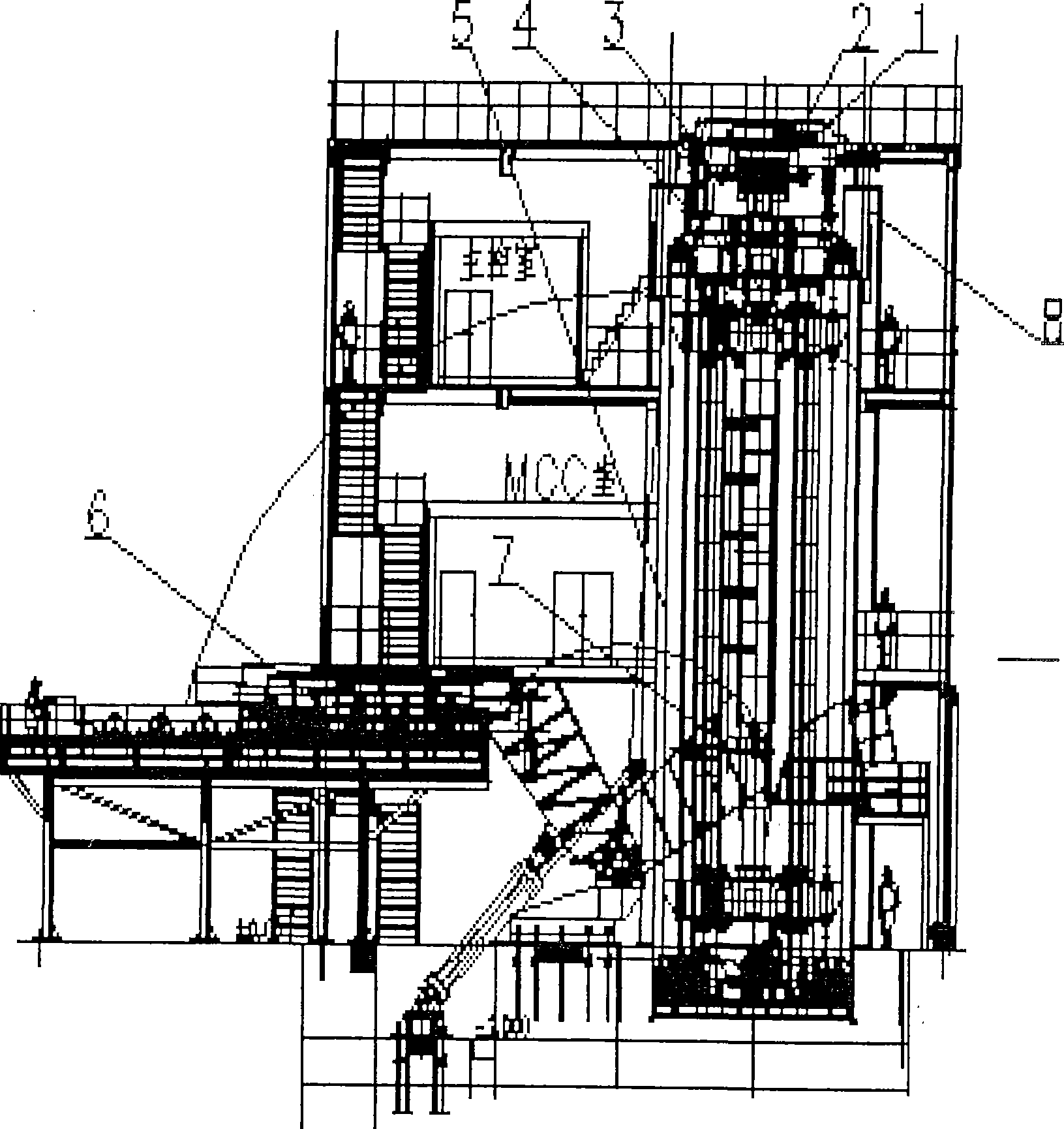

[0017] The extra-large section round billet continuous casting machine of the present invention mainly includes: water-cooled crystallizer 1, mold electromagnetic stirring system 2, crystallizer vibration device 3, ingot holding device 4, protection and heat preservation section 5, billet discharge device 6, and ingot removal device 7 and secondary cooling chamber 8.

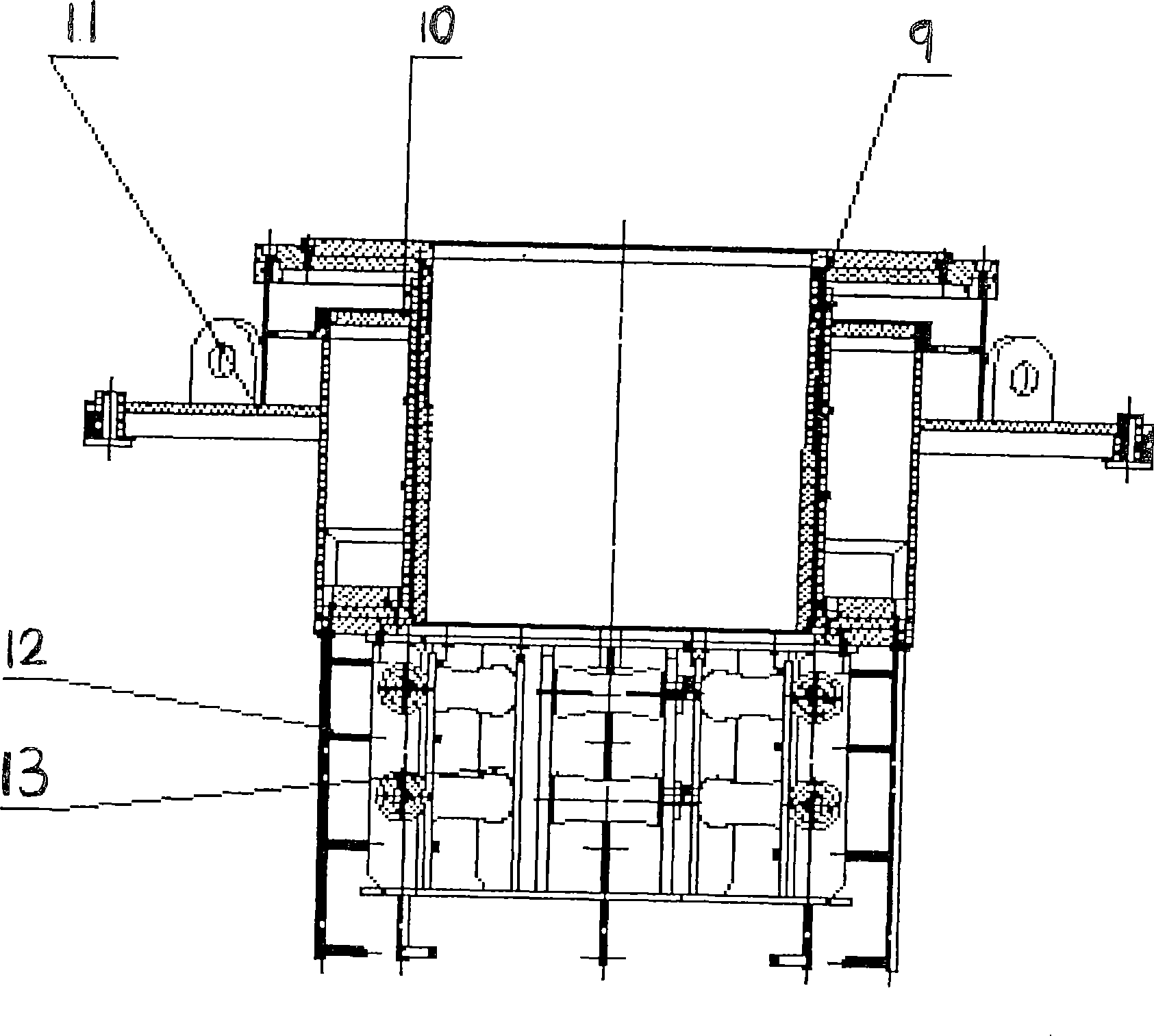

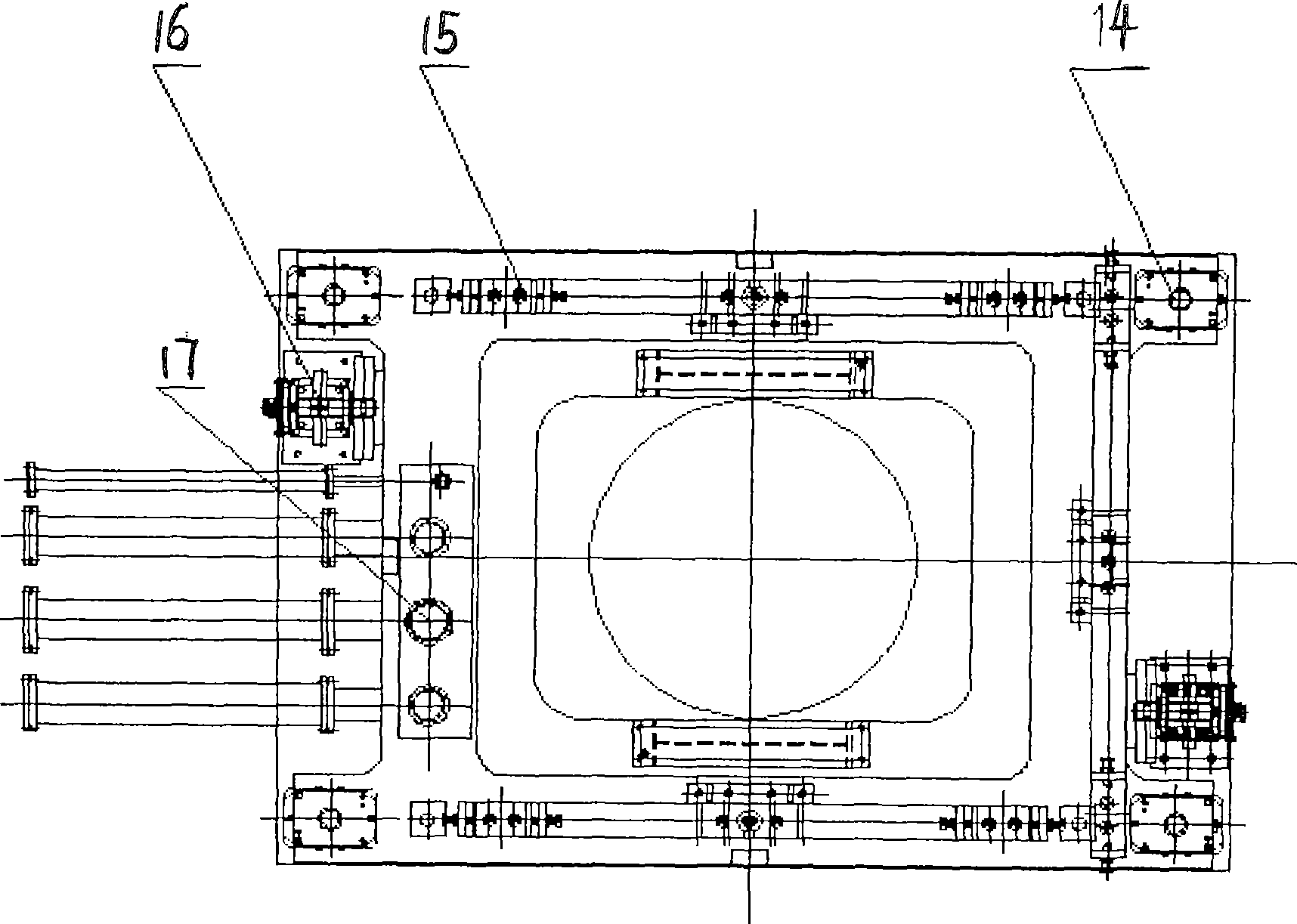

[0018] The cross-section of the water-cooled crystallizer 1 is very large, and the crystallizer water tank 11 is designed with a strong cooling structure. In order to ensure that the thickness of the exit billet shell meets the requirements, the crystallizer water tank 11 adopts a system of one inlet, two outlets, and one cooling cycle. The taper and water gap design of the mold copper tube 9 fully ensure the effective contact heat conduction between the cast slab and the mold surface. Keep casting bad until contact at the exit of the mold to reduce possible cracks and surface defects such as dimples. The taper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com