Method for producing bamboo thread sheet material

A manufacturing method and bamboo silk technology, applied in the fields of bamboo or glass composite materials and wood-based panels, can solve problems such as uncertainty, rough bamboo curtains, and difficult quality control, and achieve the effects of saving manpower and material resources, easy quality control, and manpower saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

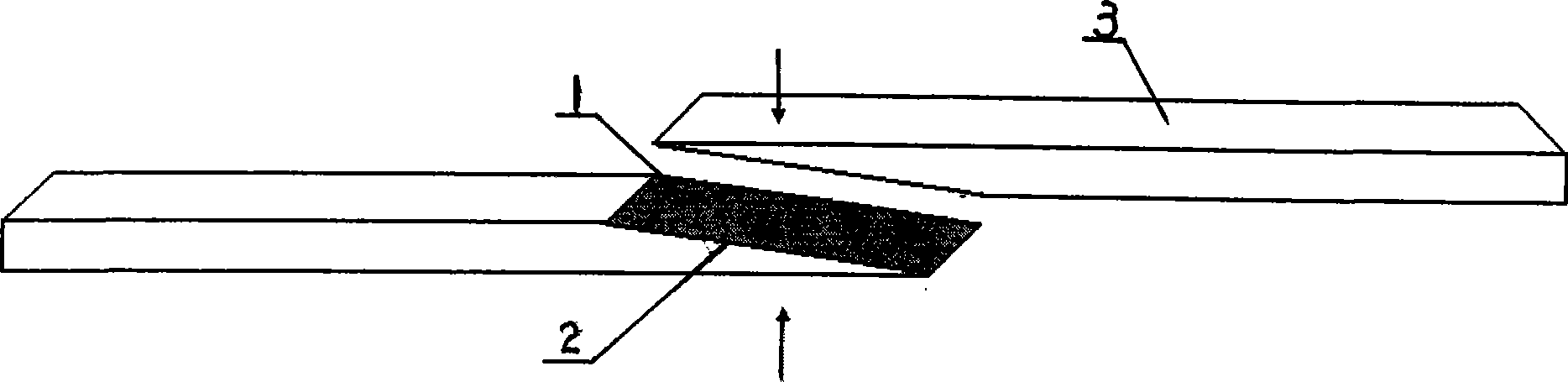

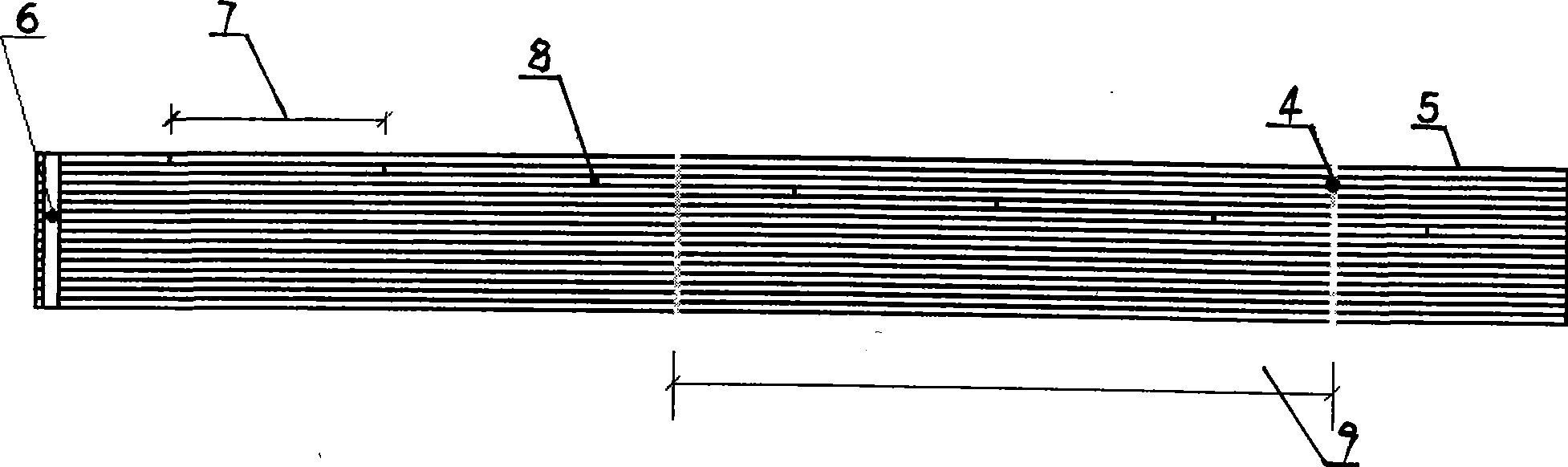

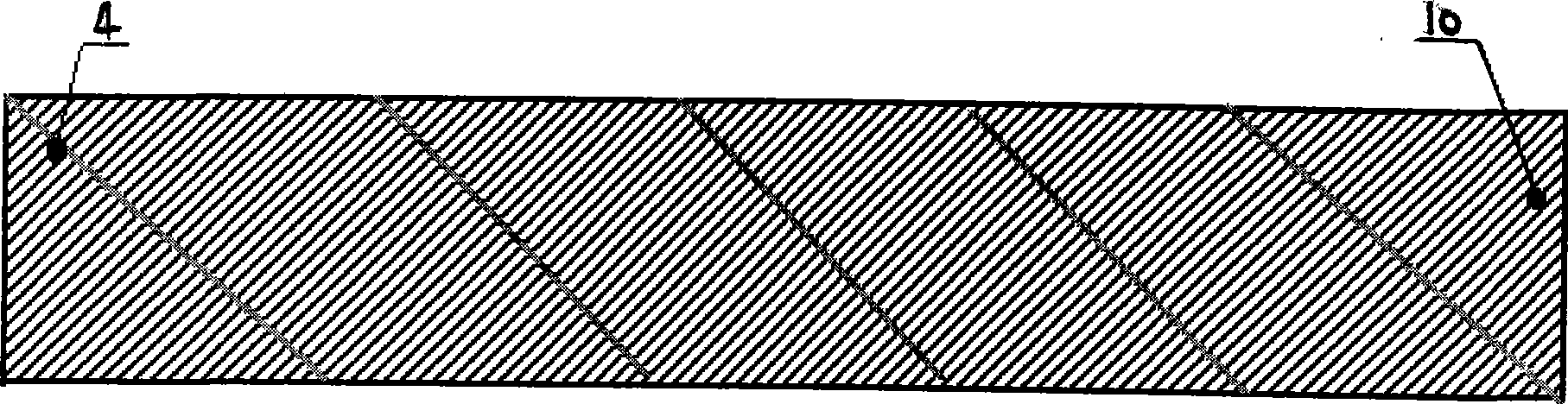

[0022] Such as Figure 1 to Figure 3 As shown, (1) the collection of bamboo, the collection of bamboo needs to have clear records of bamboo species, collection place, collection time, collection quantity, collection person, bamboo age, diameter at breast height, length and diameter.

[0023] (2) Visual classification of bamboo, classifying the diameter, length, tip diameter, bending degree and defects of bamboo.

[0024] (3) The processing of bamboo stalks. The processing of bamboo stalks is cut by circular saw. The length refers to the regulations. The length of bamboo stalks is the net length dimension. Classification, bamboo stalk length modulus is the net length dimension.

[0025] (4) The processing of bamboo strips, the processing method of wool strips is the mechanical breaking of the colliding machine, the width of the strips is generally 18±2mm, the thickness of the strips needs to be uniform, and the thickness error of the same group of strips should not exceed ± 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com