Optimal dissolved oxygen control method for producing magnetosome by cultivating magnetotactic bacteria

A control method and technology of magnetosomes, applied in bacteria and other directions, can solve the problems that the speed cannot keep up with the increase rate of cells, the decline of magnetosome volume, and the decline of magnetosome yield, etc., to achieve fast cell growth and cell yield. High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 The method of cultivating magnetobacteria to produce magnetosomes

[0042] (1) In the culture medium containing 0.03g / L sodium lactate, 0.05g / L ammonium chloride and 0g / L ferric citrate, shake culture Magnetospira MSR-1, obtain seed culture solution, wherein said culture medium initial pH The value is 6.5;

[0043] (2) Add K-free in 42L automatic fermenter 2 HPO 4 The above culture medium was sterilized, continuously fed with sterile air (0.3L / min), and continuously stirred at 100rpm. When the temperature of the culture medium dropped below 40°C, add pre-sterilized K 2 HPO 4 The final concentration is 0.1g / L. When the temperature of the culture medium drops to 35°C, inoculate the seed solution activated in step (1) into the tank, and adjust and control the pH to 6.5 with hydrochloric acid;

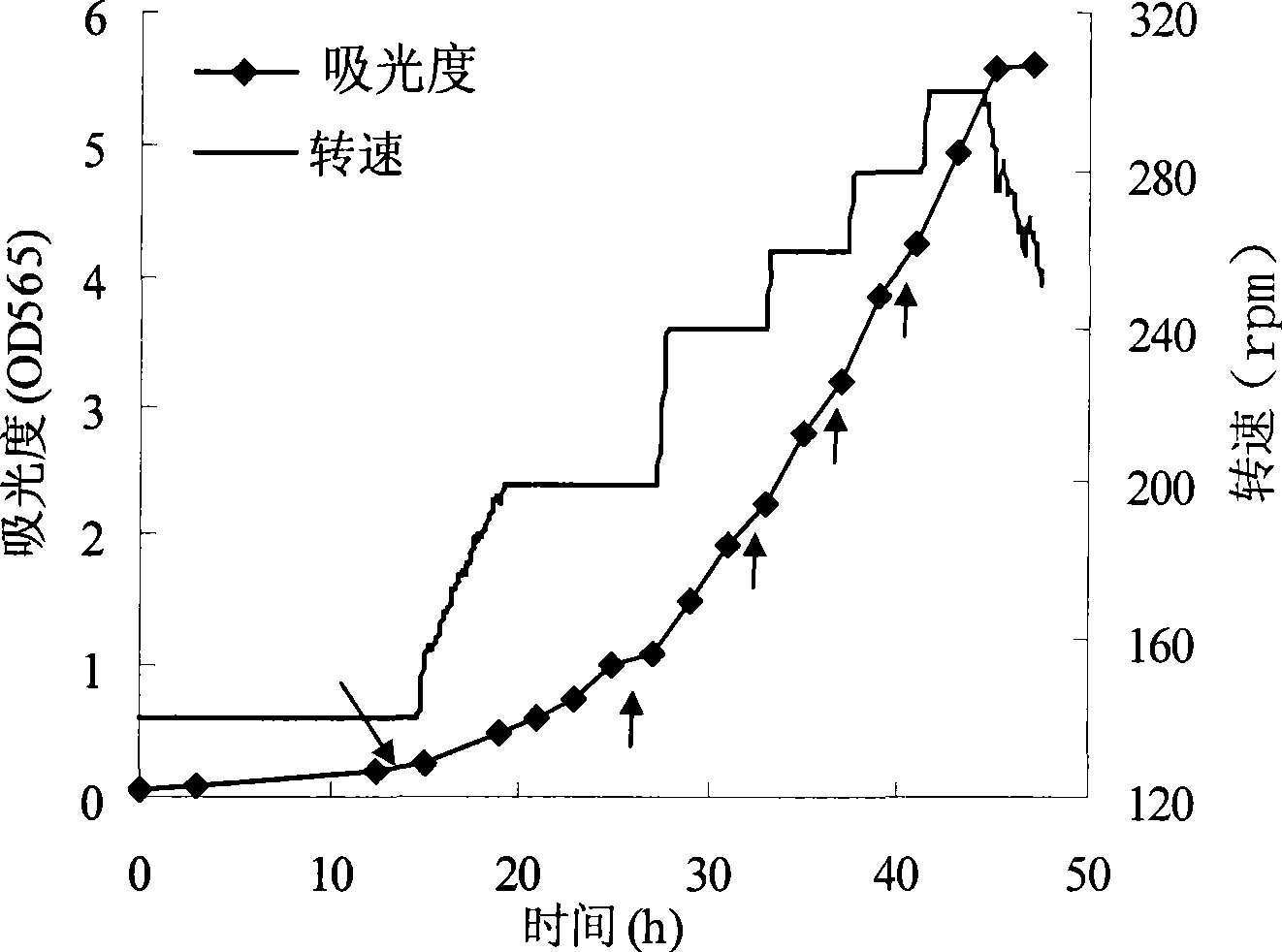

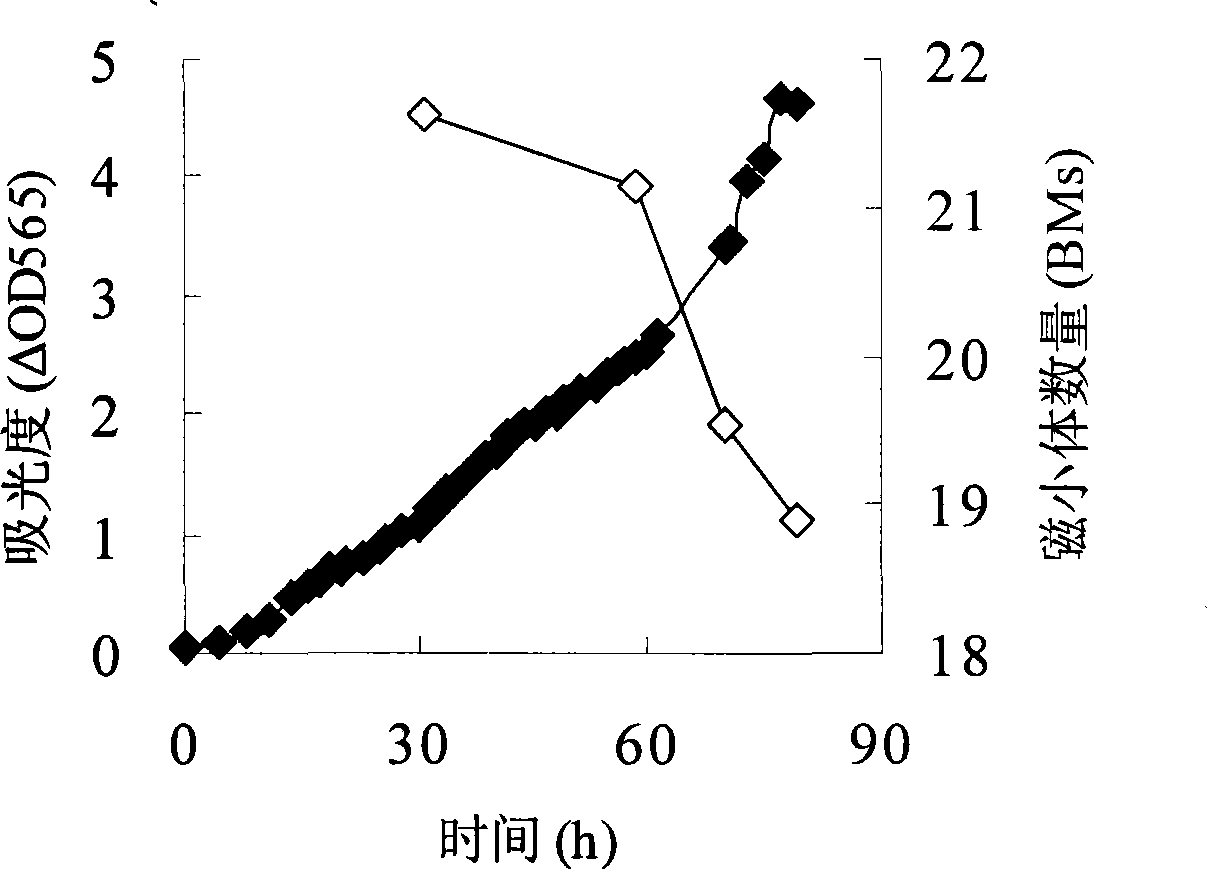

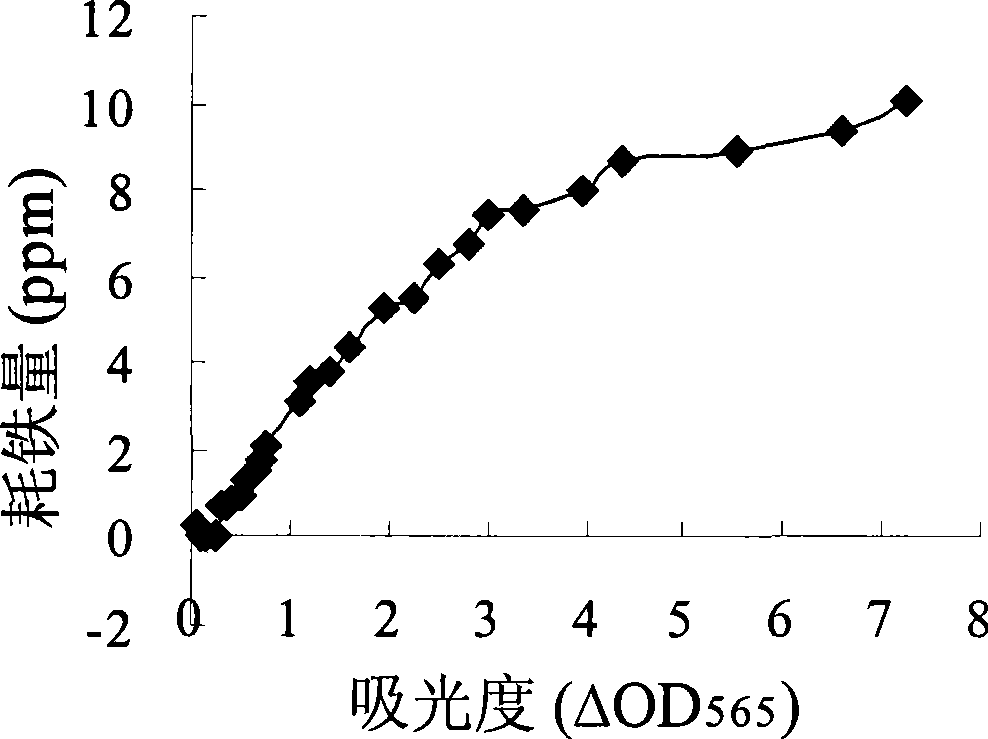

[0044] (3) During the culture process, samples were taken every 2 hours to detect the cell density and lactic acid content and the iron content of the culture solutio...

Embodiment 2

[0047] Example 2 The method of cultivating magnetobacteria to produce magnetosomes

[0048] (1) In the culture medium that contains 10.4g / L sodium lactate, 3.2g / L ammonium chloride and 2.08mg / L iron citrate, shake and cultivate Magnetospira MSR-1, obtain seed culture solution, wherein said culture medium initially The pH value is 7.5;

[0049] (2) Add K-free in 42L automatic fermenter 2 HPO 4 After the above-mentioned culture medium was sterilized, the sterile air (1.5L / min) was continuously fed in, and the stirring was continued at 200rpm. When the temperature of the culture medium dropped below 40°C, pre-sterilized K 2 HPO 4 The final concentration is 3g / L. When the temperature of the culture medium drops to 25°C, inoculate the seed solution activated in step (1) into the tank, and adjust and control the pH to 7.5 with lactic acid;

[0050] (3) During the culture process, samples were taken every 2 hours to detect the cell density and lactic acid content and the iron co...

Embodiment 3

[0053] Example 3 The method of cultivating magnetobacteria to produce magnetosomes

[0054] (1) In the culture medium that contains 2.6g / L sodium lactate, 0.61g / L ammonium chloride and 13mg / L iron citrate, shake and cultivate Magnetospira MSR-1, obtain seed culture solution, wherein said culture medium initial pH Value is 7.0;

[0055] (2) Add K-free in 42L automatic fermenter 2 HPO 4 The above culture medium was sterilized, continuously fed with sterile air (0.3L / min), and continuously stirred at 100rpm. When the temperature of the culture medium dropped below 40°C, add pre-sterilized K 2 HPO 4 The final concentration is 0.5g / L. When the temperature of the culture medium drops to 28°C, inoculate the seed solution activated in step (1) into the tank, and adjust and control the pH to 7.0 with hydrochloric acid;

[0056] (3) During the culture process, samples were taken every 2 hours to detect the cell density and lactic acid content and the iron content of the culture sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com