Non-reagent ground dipping uranium extracting process flow

A process flow and technology for uranium mining by in-situ leaching, which is applied in the fields of mining fluid, earth cube drilling, wellbore/well components, etc., can solve the problem of inability to eliminate chemical blockage of ore beds and production systems, reduce the production time rate and product output of uranium wells, Unable to remove chemical deposits and other problems, achieve significant anti-blocking effect, increase production time rate and product output, and mature unit operation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

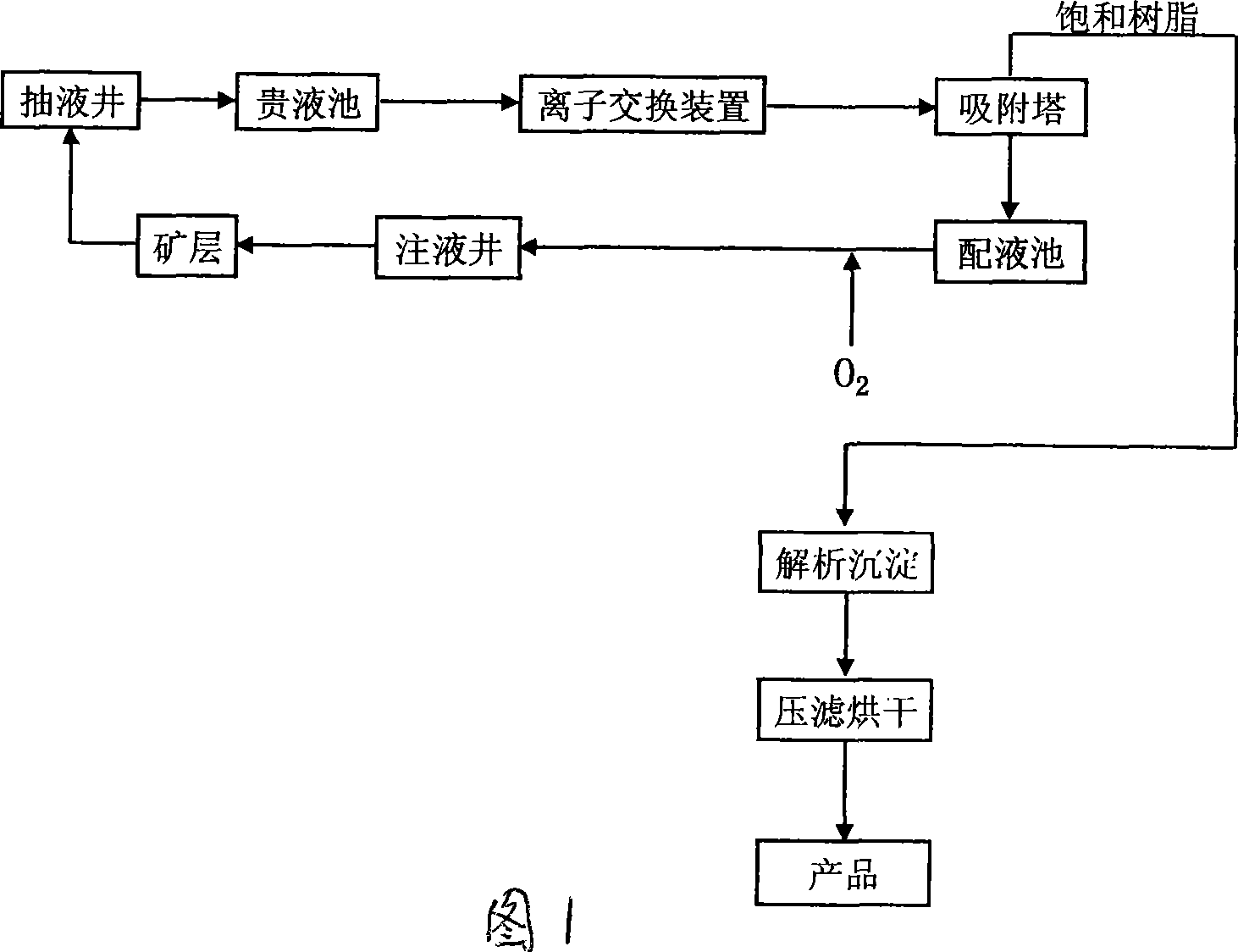

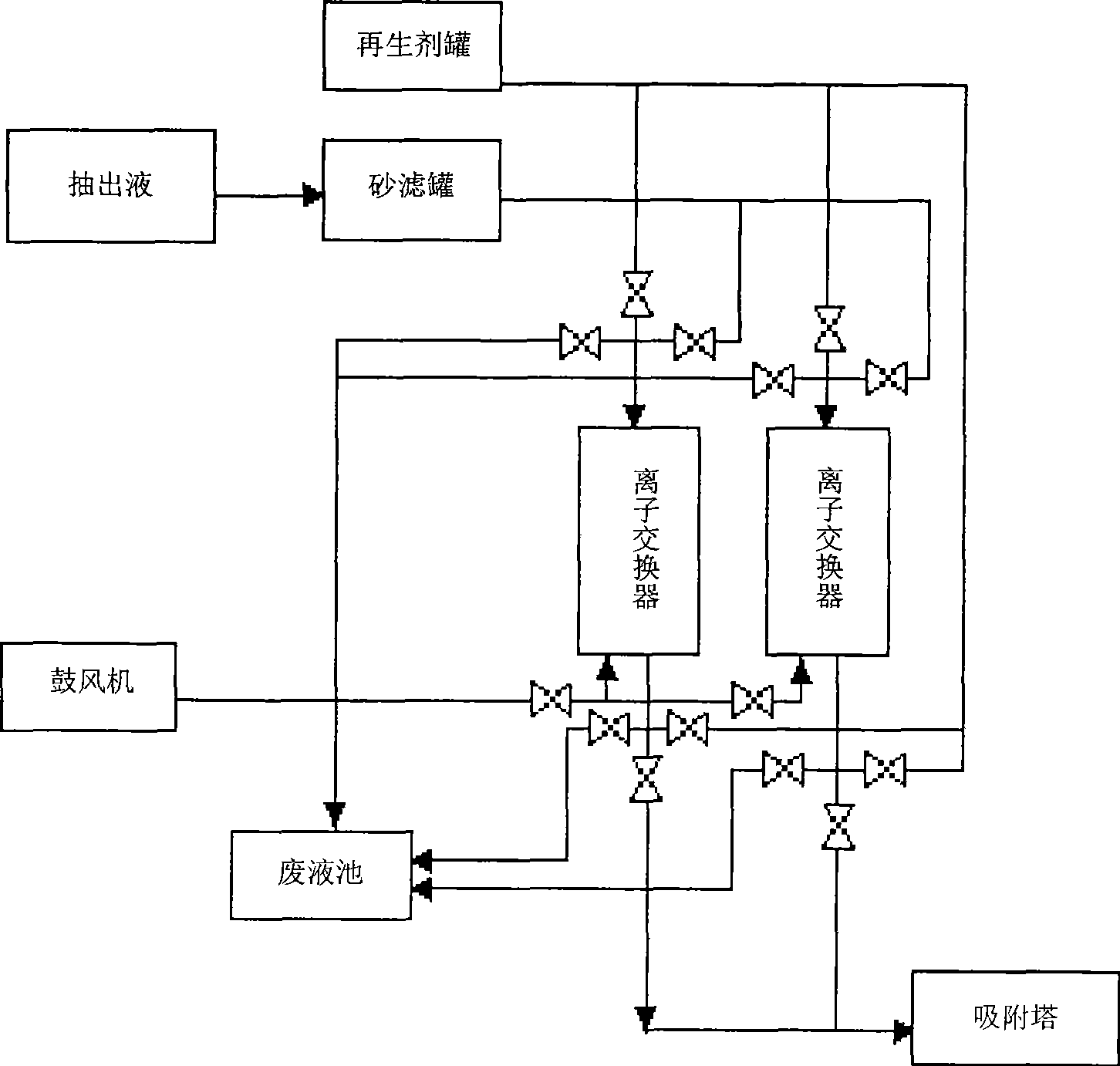

[0008] As shown in the figure, the conventional reagent-free in-situ leaching uranium mining process is composed of multiple links such as ore bed, liquid pumping well, expensive liquid pool, adsorption tower, liquid mixing pool, liquid injection well, etc. Dried into products. The present invention adds a set of ion exchange device consisting of an ion exchanger, a sand filter tank, a regeneration agent tank and a waste liquid pool before the adsorption tower on the basis of the process flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com