Method for processing recombined dried meat

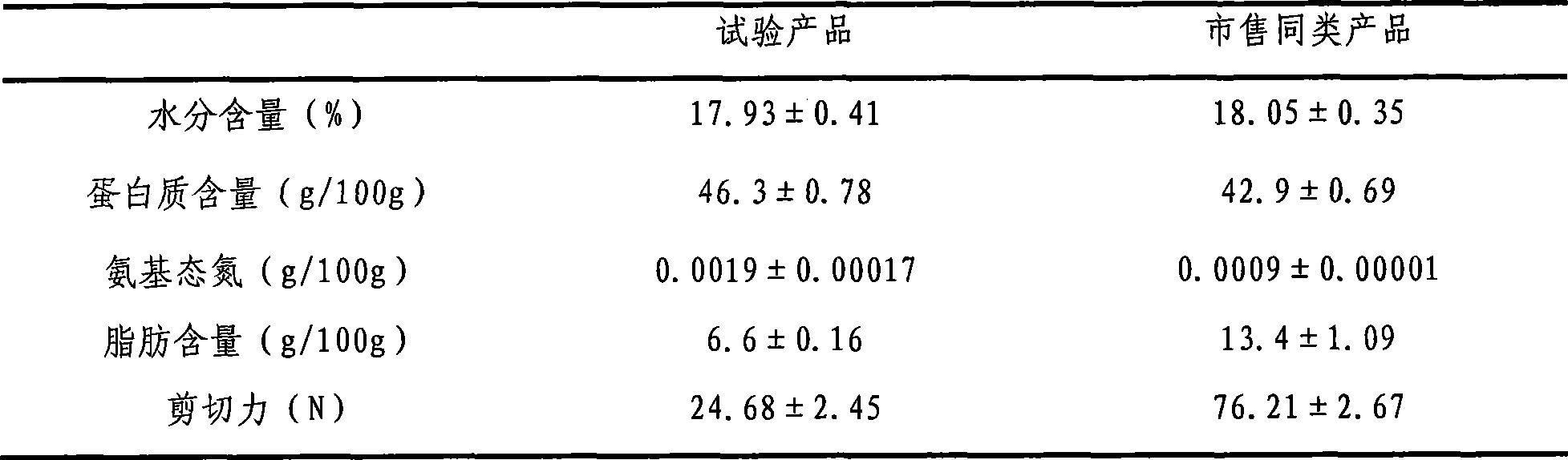

A processing method and technology of recombined meat, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of lack of compound use of enzymatic modification technology, and achieve the effect of low hardness, bright color and soft taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A processing method for recombined jerky, comprising the steps of:

[0019] (1) Raw materials: Remove the fat and dirt on the surface of the fresh meat, wash it, drain it, and cut it into similar sizes, each piece is about 0.5-1kg;

[0020] (2) Tenderization treatment of bromelain: according to the amount of 0.46mg / g meat sample, weigh bromelain (specific activity unit: 1200μ / g) and dilute it into a bromelain solution, and inject it at different parts of the meat. Roll and knead for 10 minutes, and react at 40°C for 1.5 hours until the enzyme fully reacts.

[0021] (3) Pickling: Weigh various ingredients according to the pickling formula, wherein the seasoning is: per kilogram of beef, the pickling formula is: 45g white sugar, 8g white wine, 1g each of pepper, fennel, and licorice, and 1.6g of aniseed (star anise) , cinnamon 2g, orange peel 10g, ginger 5g, the amount of salt added is 1.5g / 100g beef:

[0022] Grind the ingredients into powder and boil with water for 0....

Embodiment 2

[0031] A processing method for recombined jerky, comprising the steps of:

[0032] (1) Raw materials: Remove the fat and dirt on the surface of the thawed meat, wash it, drain it, and cut it into similar sizes, each piece is about 0.5-1kg.

[0033] (2) Tenderization treatment of bromelain: according to the amount of 0.46mg / g meat sample, weigh bromelain (specific activity unit: 1200μ / g) and dilute it into a bromelain solution, and inject it at different parts of the meat. Roll and knead for 20 minutes, and react at 40°C for 1.5 hours until the enzyme fully reacts.

[0034] (3) Pickling: Weigh various ingredients according to the pickling formula, grind the ingredients into powder and boil with water for 1 hour to obtain a pickling solution. Marinate the enzyme-treated beef cubes with a pickling solution for 12 hours at 2-4°C to taste.

[0035] (4) Mixing and forming: Drain the marinated beef and divide it into two parts. One part is steamed and matured and chopped into meat ...

Embodiment 3

[0038] A processing method for recombined jerky, comprising the steps of:

[0039] (1) Raw materials: Remove the fat and dirt on the surface of the fresh meat, wash it, drain it, and cut it into similar sizes, each piece is about 0.5-1kg.

[0040] (2) Tenderization treatment of bromelain: according to the amount of 0.46mg / g meat sample, weigh bromelain (specific activity unit: 1200μ / g) and dilute it into a bromelain solution, and inject it at different parts of the meat. Roll and knead for 20 minutes, and react at 40°C for 1.5 hours until the enzyme fully reacts.

[0041] (3) Pickling: Weigh various ingredients according to the pickling formula, wherein the seasoning is: per kilogram of beef, the pickling formula is: 90g soy sauce, 45g white sugar, 8g white wine, 1g each of pepper, fennel, licorice, aniseed (star anise ) 1.6g, cinnamon 2g, clove 0.6g, orange peel 10g, ginger 5g. Wherein the addition amount of salt is 1.5g / 100g. Grind the ingredients into powder and boil with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com