Diabetes-treating medicament Gliclazide tablet convenient for dividing dose and method for producing the same

A technology for diabetes drugs and production methods, which is applied in the direction of drug combinations, pharmaceutical formulas, and medical preparations containing active ingredients, etc., can solve the problems of complex processes and high manufacturing costs, and achieve simple processes, low production costs, and accurate dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

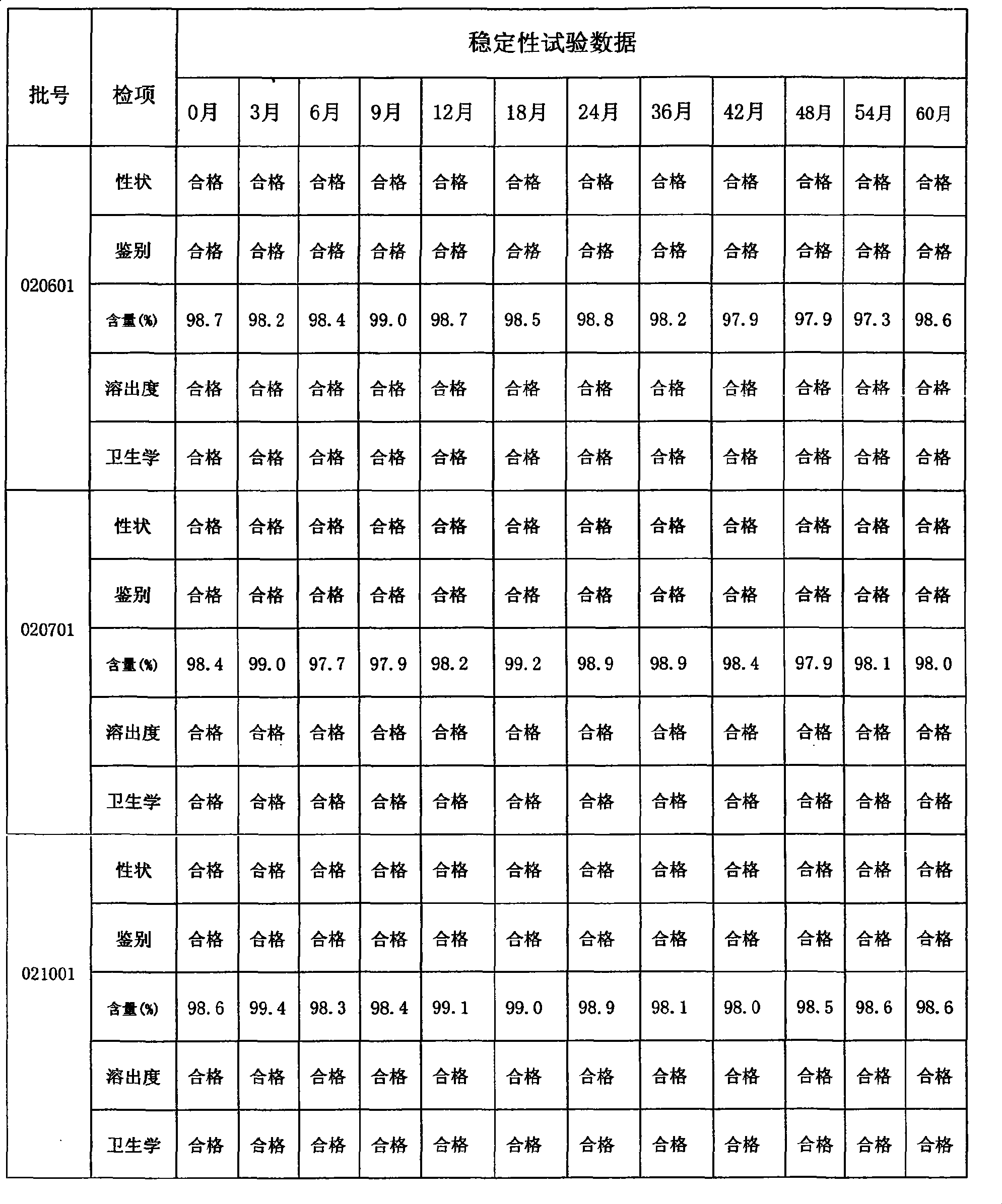

Image

Examples

Embodiment 1

[0044] Gliclazide tablets (80mg / tablet), in terms of 1000 tablets, its formula is:

[0045] Raw material name Weight (unit: gram)

[0046] Gliclazide 80 (fold scalar)

[0047] Starch 70

[0048] Sodium carboxymethyl starch 8

[0049] Slurry starch 8 (add appropriate amount of purified water to make 8% starch slurry)

[0051] The production method is as follows: after mixing gliclazide with 100-mesh starch and carboxymethyl starch sodium, add 8% starch slurry to make soft material, 16-mesh sieve to make granules, and dry the wet granules in a boiling dryer. 60-70°C, drying time about 30-40 minutes, sieve the dry granules with a 16-mesh sieve, add 80-mesh magnesium stearate and mix evenly, test the content to determine the tablet weight, use flat cross punching tablets, and pack.

Embodiment 2

[0053] Gliclazide tablets (80mg / tablet), in terms of 1000 tablets, its formula is:

[0054] Raw material name Weight (unit: gram)

[0055] Gliclazide 80 (fold scalar)

[0056] Starch 60

[0057] Dextrin 10

[0058] Crystalline Cellulose 8

[0059] Slurry starch 8 (add appropriate amount of purified water to make 8% starch slurry)

[0061]The production method is: mix gliclazide with 100 mesh starch, dextrin, and crystal cellulose, add 8% starch slurry to make soft material, 16 mesh sieve to make granules, and dry the wet granules in a boiling dryer , the temperature is 60-70°C, the drying time is about 30-40 minutes, the dry granules are sieved with a 16-mesh sieve, and the 80-mesh magnesium stearate is added and mixed evenly. .

Embodiment 3

[0063] Gliclazide tablets (80mg / tablet), in terms of 1000 tablets, its formula is:

[0064] Raw material name Weight (unit: gram)

[0065] Gliclazide 80 (fold scalar)

[0066] Starch 50

[0067] Dextrin 20

[0068] Sodium carboxymethyl starch 5

[0069] Low-substituted hydroxypropyl cellulose 3

[0070] Slurry starch 8 (add appropriate amount of purified water to make 8% starch slurry)

[0072] The production method is as follows: after mixing gliclazide with 100-mesh starch, dextrin, sodium carboxymethyl starch, and low-substituted hydroxypropyl cellulose, add 8% starch slurry to make soft material, and 16-mesh sieve to make granules . The wet granules are dried in a boiling dryer at a temperature of 60-70°C, and the drying time is about 30-40 minutes. The dry granules are sieved with a 16-mesh sieve, added with 80-mesh magnesium stearate and mixed evenly. The content is determined to determine the tablet weight. It adopts flat cross stamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com