Highly electron conductive polymer and electrochemical energy storage device with high capacity and high power using the same

A conductive polymer, polymer technology, applied in the direction of battery electrodes, non-aqueous electrolyte batteries, conductors, etc., can solve the problem of not being able to increase the capacity of energy storage devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1-1. Preparation of conductive polymer with enhanced electrical conductivity by introducing salt / applying voltage

[0063] Will be made of PEDOT (polyethylenedioxythiophene) (molecular weight 30,000; adhesion: 10g / cm or greater; conductivity: ~ 1 × 10 -5S / cm) The conductive polymer film that forms is coated on the platinum plate, and it is applied the voltage of 1V (relative to Ag / AgCl) 1 hour, at the same time, described conductive polymer film is immersed in the HCl solution of 2% by weight to The doped polymer PEDOT is provided. Platinum was used as a counter electrode.

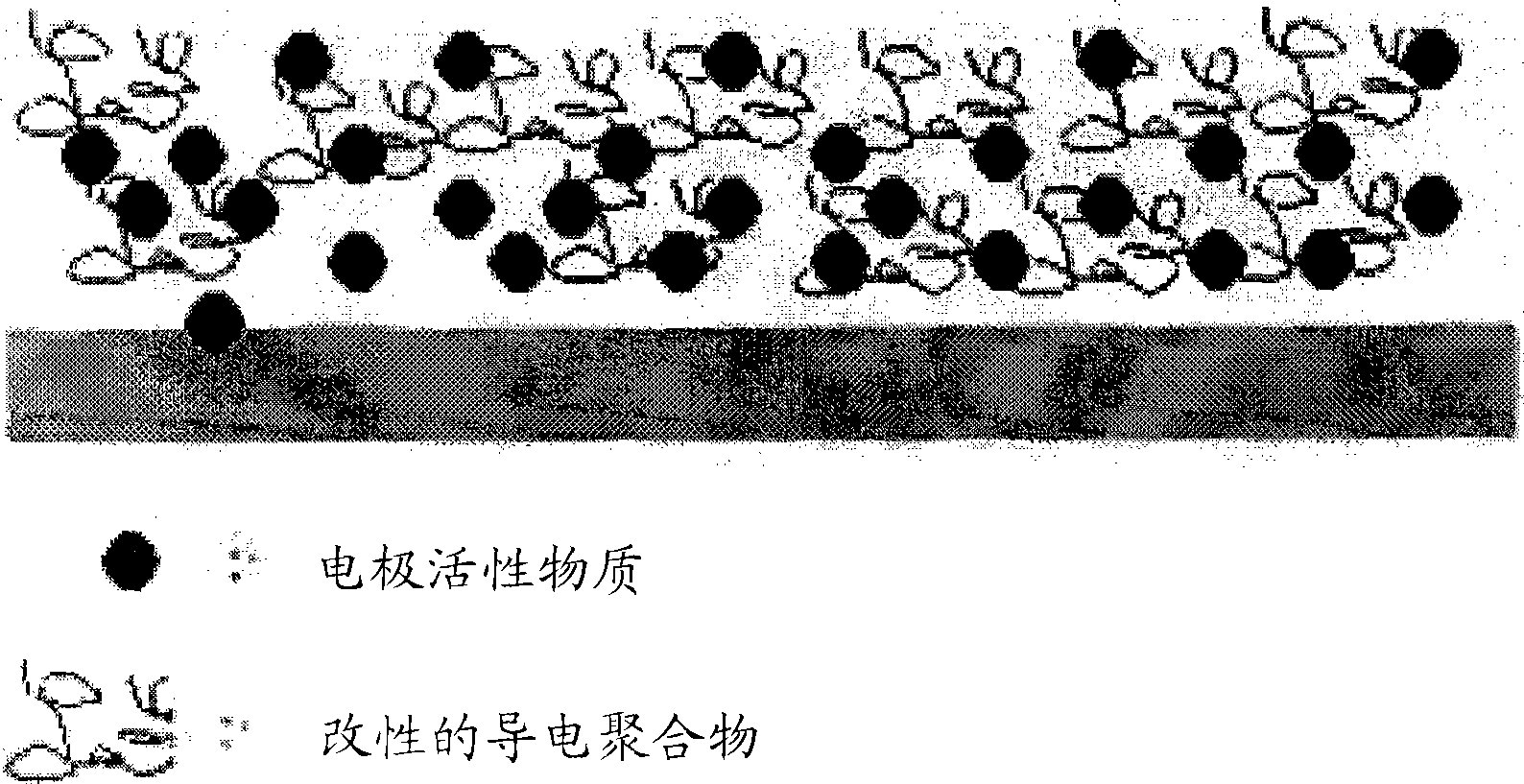

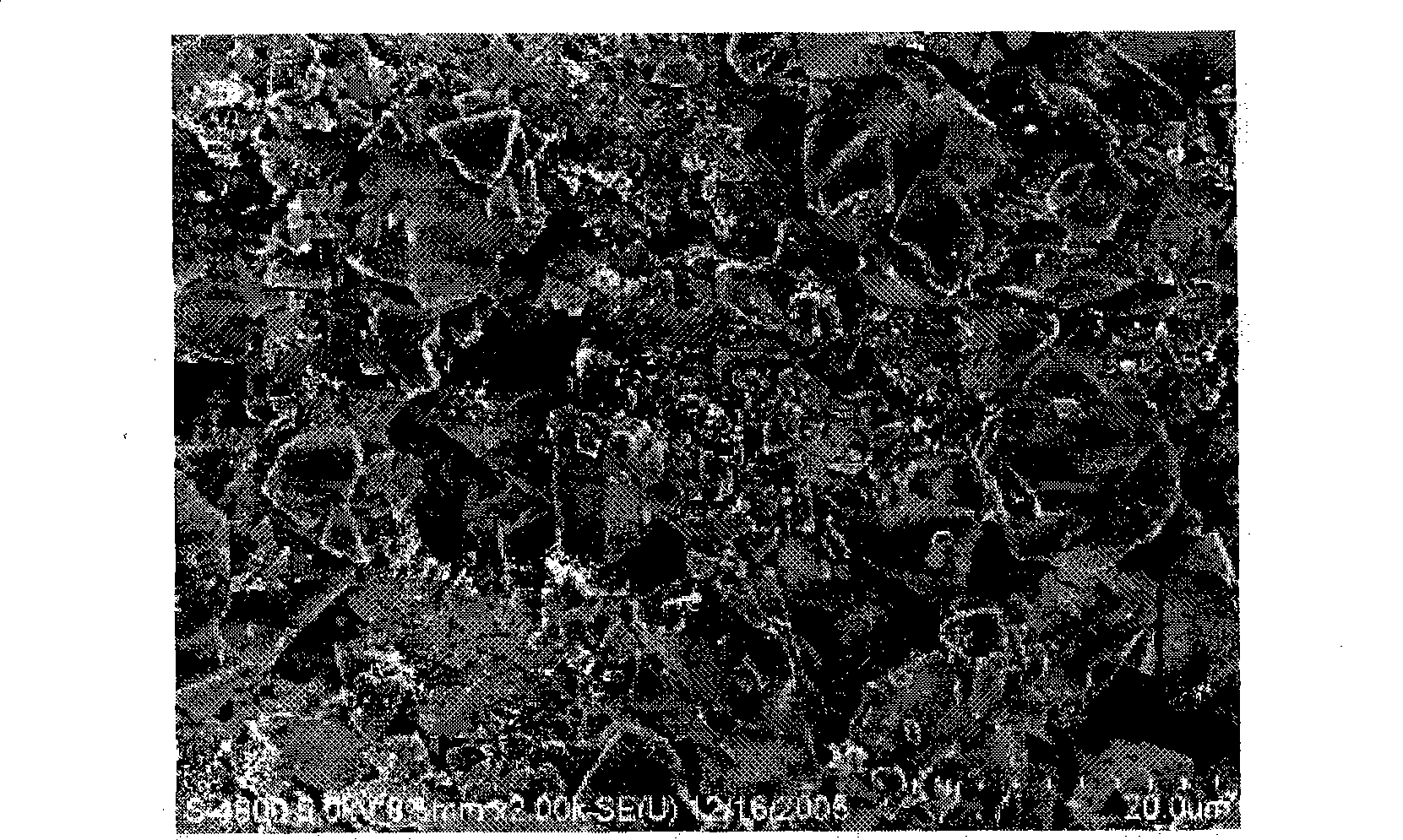

[0064] 1-2. Manufacturing electrodes

[0065] Add 90% by weight of activated carbon (MSP20, Kansai Coke and Chemicals Co., Ltd.) and 10% by weight of the modified conductive polymer PEDOT prepared in Example 1-1 as an electrode active material to distilled water as a solvent, to provide a binary mixture as an electrode paste. The electrode slurry was applied onto an aluminum (Al) foil having...

experiment Embodiment 1

[0075] Experimental Example 1. Comparison and Evaluation of Electronic Conductivity

[0076] The modified high electronic conductivity polymer (PEDOT) of Example 1 is used as a sample, and the polymer (PEDOT) currently used as a conductive agent in lithium secondary batteries and electric double layer capacitors and carbon nanotubes (CNT) is generally used as a high Super-P, which is an electronic conductivity material, was used as a control. The above materials were pelletized separately, and the electronic conductivity of each material was measured using a four-probe method.

[0077] After this test, it can be seen that the high electronic conductivity polymer (PEDOT) of the present invention has an excellent electrical conductivity compared with the conventional conductive agent Super-P, and exhibits an electronic conductivity comparable to that of carbon nanotubes (see Table 1 below). This demonstrates that the conductive polymer is sufficient as a conductive agent in ba...

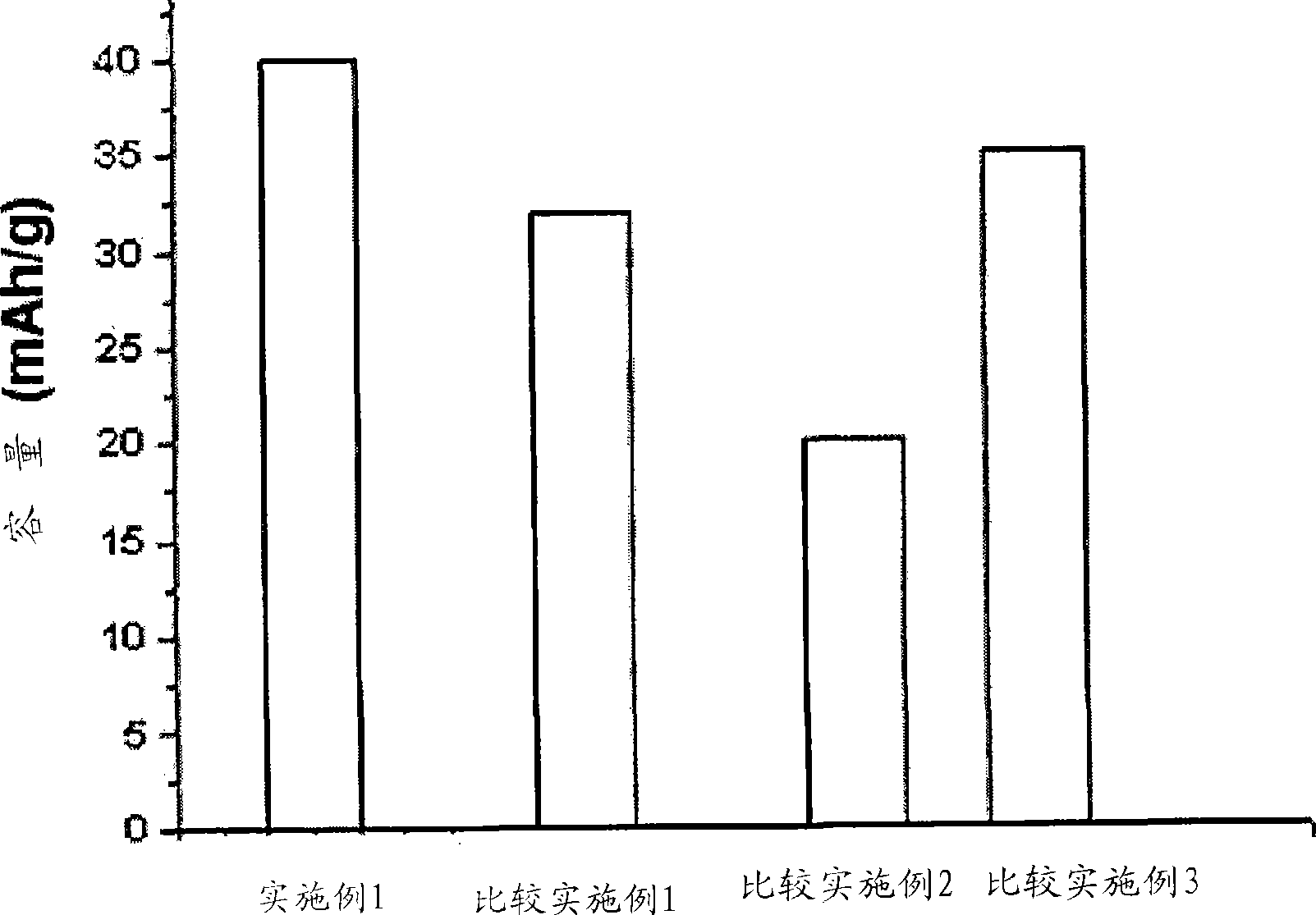

experiment Embodiment 2

[0080] Experimental Example 2. Adhesion test

[0081] The following tests were conducted to evaluate the electrode adhesion of Example 1 and Comparative Examples 1-3.

[0082] The adhesion test was conducted by attaching a tape to the surface of the electrode active material layer of each electrode and peeling off the tape. The amount of each electrode active material layer remaining on the tape after the tape was removed is shown in Table 2 below.

[0083] After this test, it can be seen that the electrode of Comparative Example 1 using a binder (PTFE) was slightly contaminated with the electrode active material. In contrast, each of the electrodes using the conductive polymer of Example 1 and Comparative Examples 2 and 3 was not contaminated with the electrode active material (see Table 2 below). This demonstrates that the conductive polymer can be used as a high-quality adhesive.

[0084] [Table 2]

[0085] condition

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com