Machining process of engine connecting rod

A technology of engine connecting rod and processing technology, applied in the field of processing technology of internal combustion engine connecting rod, can solve problems affecting the quality and use of connecting rods, time-consuming joint surface processing, large assembly errors, etc., to save processes and prevent crankshaft hole accuracy The effect of error and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

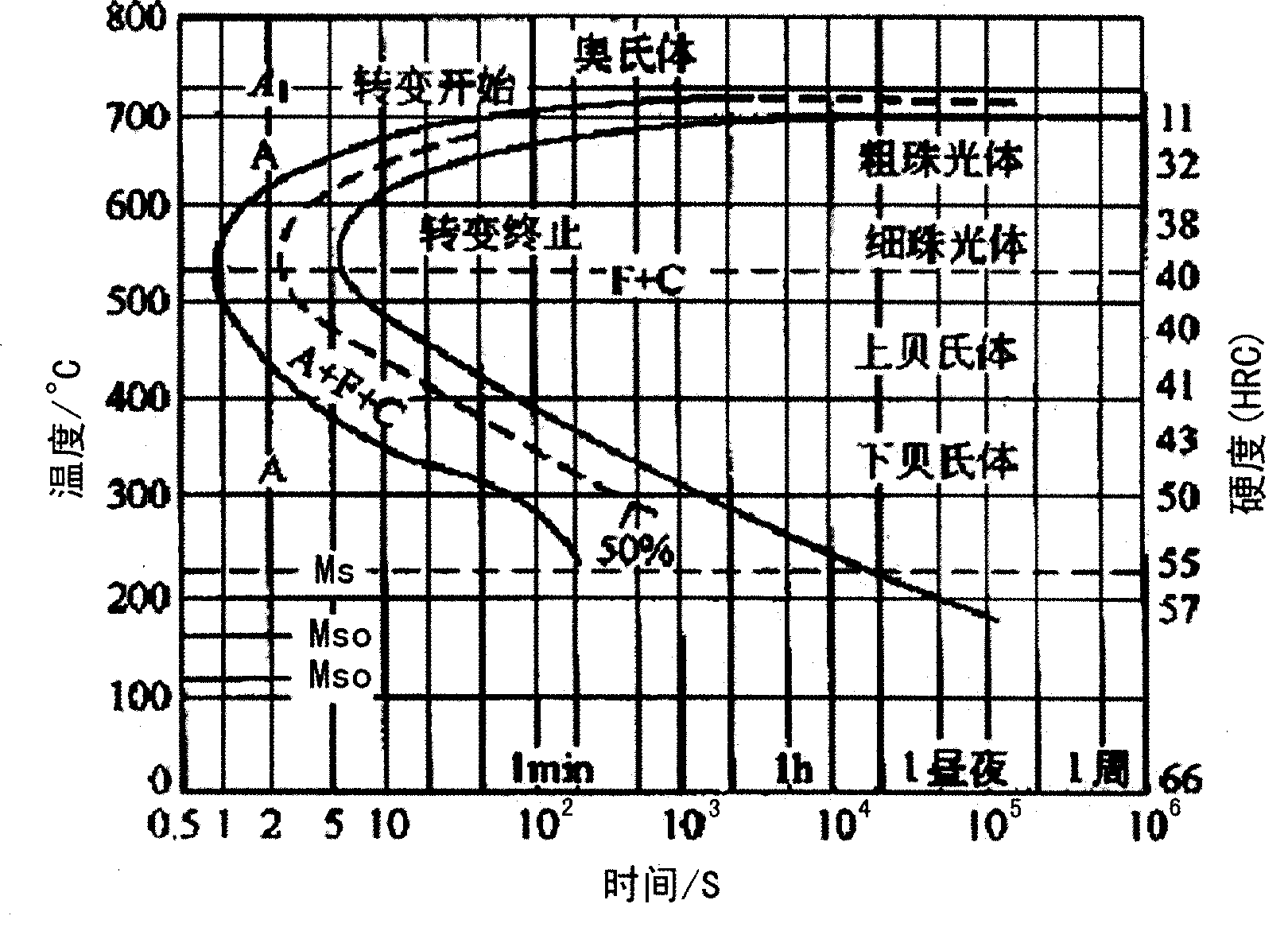

[0017] A processing technology for an engine connecting rod, which includes the following steps: forging and pressing a billet, cutting, and the raw material is high-carbon non-quenched and tempered steel C70S6; the main process of forging and pressing a billet: blanking; heating, the heating temperature is 1150 ° C, and the temperature is control ±50℃; billet making; pre-forging, final forging, pre-forging temperature is 1100 ℃, end forging temperature ≥ 930 ℃; edge trimming, punching, shaping, normalizing, and forced cooling with strong cooling, so that the forging The temperature drops below 600°C within 10 minutes; then cutting is carried out after flaw detection and strong shot blasting.

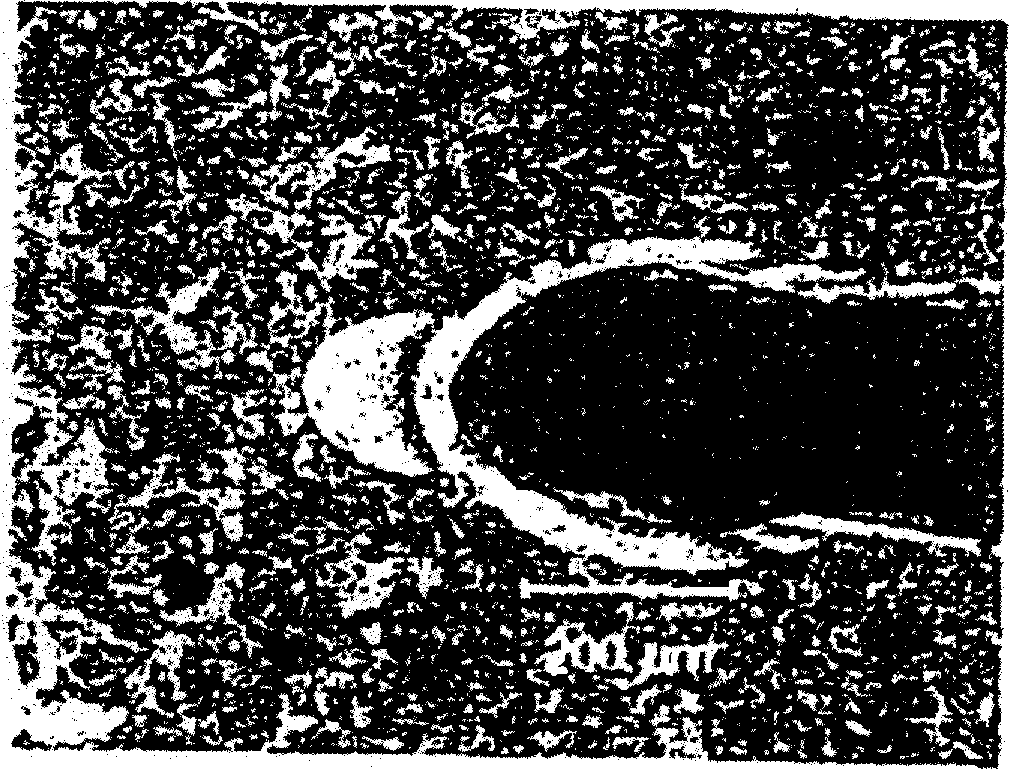

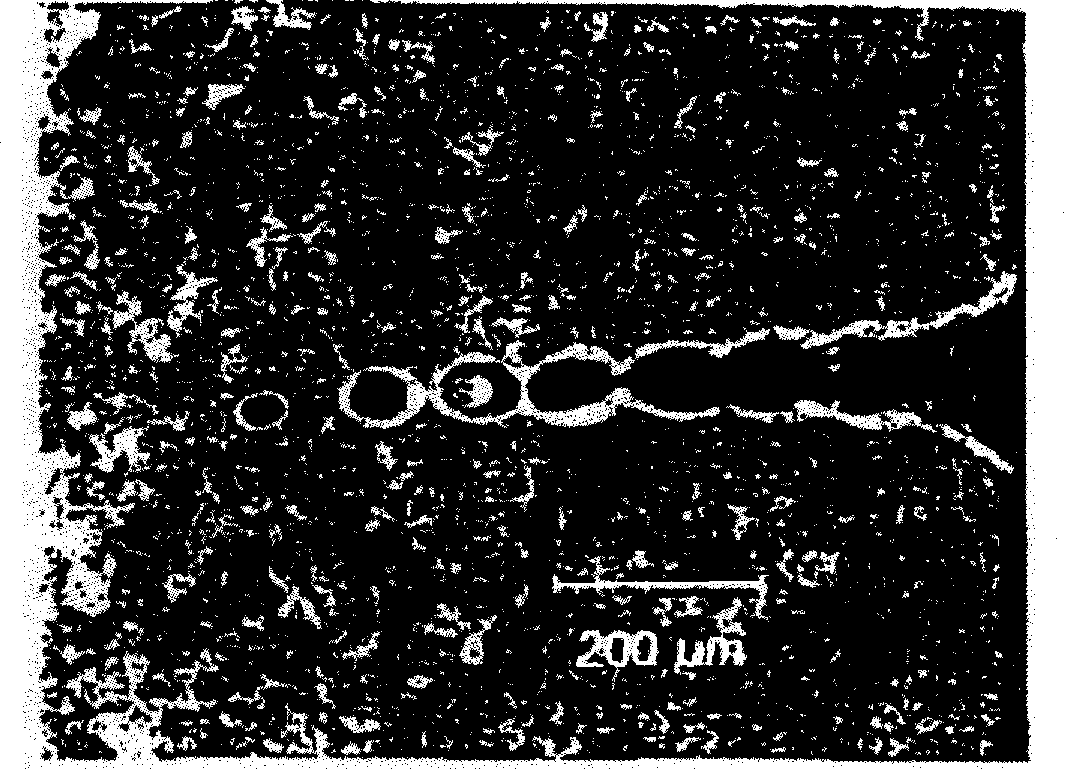

[0018] The purpose of normalizing is to obtain evenly distributed flaky pearlite and ferrite with a percentage of no more than 10% in the forging, that is, the fracture surface is magnified 100 times with a microscope, and the area seen has no more than 10% ferrite. White ferrite with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com