Chalcogenide infrared glass and preparation process thereof

A technology for infrared glass and preparation process, applied in the field of chalcogenide infrared glass and its preparation process, can solve the problems of inability to completely remove pollution, complicated operation process, etc., and achieve the effects of reducing equipment requirements, short process flow and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

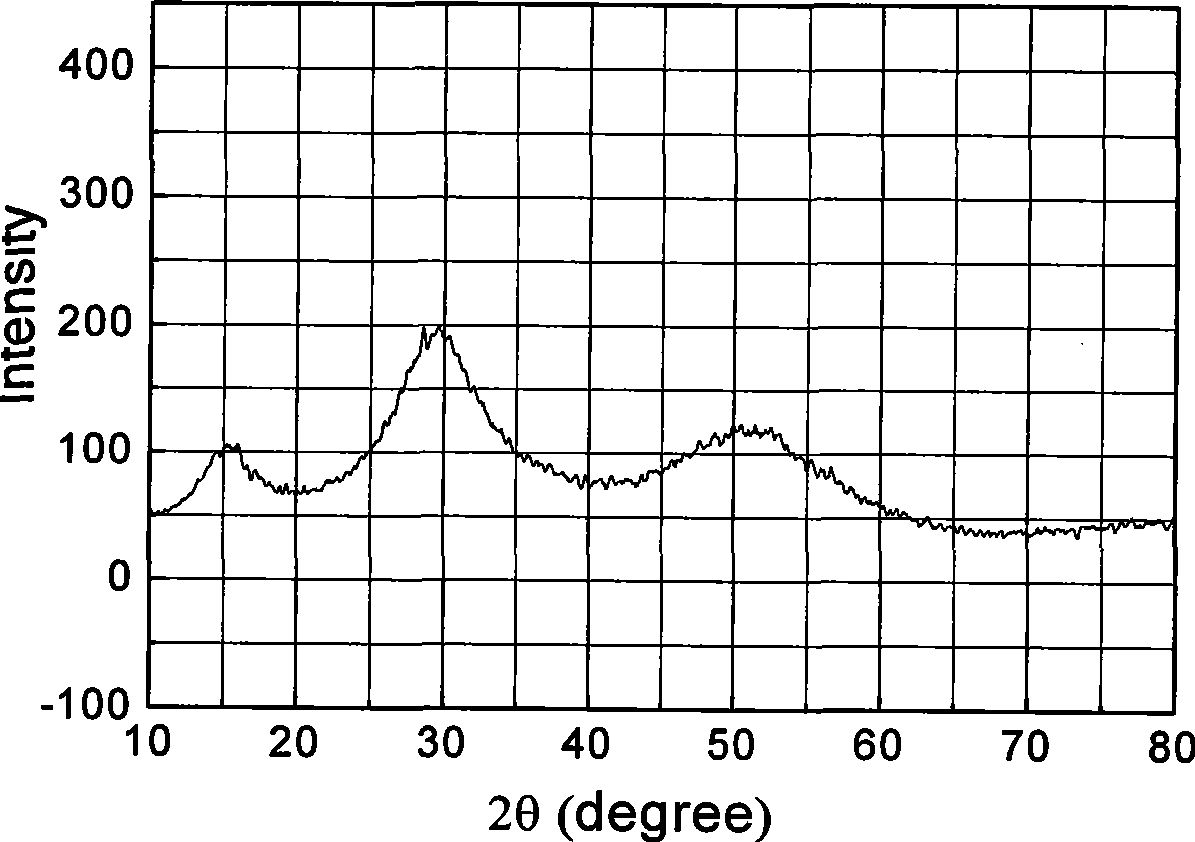

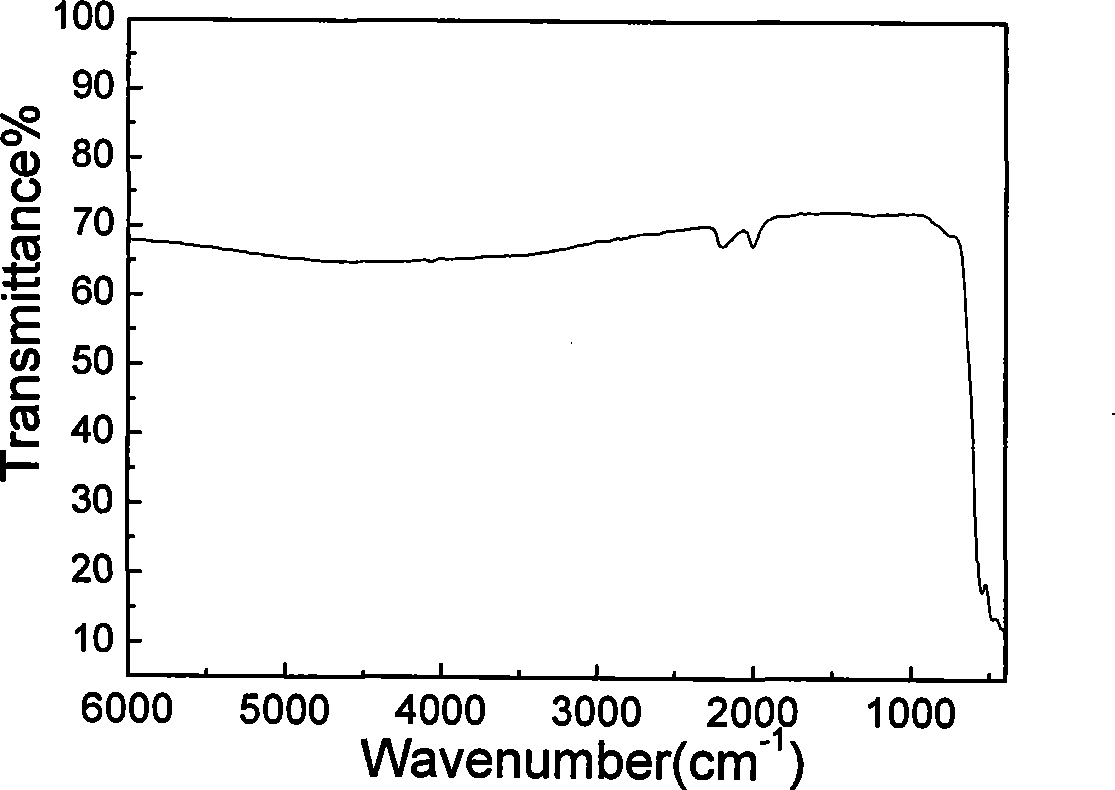

Image

Examples

Embodiment 1

[0031] A chalcogenide infrared glass, prepared by the following process, which comprises the following steps in sequence

[0032] 1. Preparation of materials:

[0033] Glass raw materials include Ge, Se, and Sb with a purity of 99.999%, and they are formulated according to the following proportions, Ge is weighed by 28 atomic percent, Se is weighed by 63 percent atomic percent, and Sb is weighed by 9 percent atomic percent , dried for later use;

[0034] The impurity-removing elements include Al, Mg and rare earth, each added by 1%wt.

[0035] 2. Sealing:

[0036] Put the raw material and impurity-removing elements into two quartz crucibles respectively, connect the two crucibles, and then evacuate and heat the quartz crucibles until the vacuum degree reaches 1×10 -4 torr, the end of the quartz crucible is gradually sealed by melting with an oxyhydrogen flame.

[0037] 3. Sintering and impurity removal:

[0038] Put the sealed quartz crucible in a well-type three-stage el...

Embodiment 2

[0041] A chalcogenide infrared glass, prepared by the following process, which comprises the following steps in sequence

[0042] 1. Preparation of materials:

[0043] Glass raw materials include Ge, Se, and Sb with a purity of 99.999%, and they are formulated according to the following proportions, Ge is weighed by 18% atomic percentage, Se is weighed by 72% atomic percentage, and Sb is weighed by 10% atomic percentage , dried for later use;

[0044] The impurity-removing elements include Al, Mg and rare earth, each added by 0.9%wt.

[0045] 2. Sealing:

[0046]Put the raw materials and impurity-removing elements into two quartz crucibles respectively, connect the two crucibles and then evacuate and heat the quartz crucibles until the vacuum degree reaches 1×10 -4 torr, the end of the quartz crucible is gradually sealed by melting with an oxyhydrogen flame.

[0047] 3. Sintering and impurity removal:

[0048] Put the sealed quartz crucible in a well-type three-stage elec...

Embodiment 3

[0051] A chalcogenide infrared glass, prepared by the following process, which comprises the following steps in sequence

[0052] 1. Preparation:

[0053] The glass raw materials include Ge, Se, and Sb with a purity of 99.999%, and they are formulated according to the following proportions, Ge is weighed by 25% atomic percent, Se is weighed by 64% atomic percent, and Sb is weighed by 11% atomic percent , dried for later use;

[0054] The impurity-removing elements include Al, Mg and rare earths, Al and Mg are added at 1.2%wt each, and the rare earths are added at 0.9%wt.

[0055] 2. Sealing:

[0056] Put the raw materials and impurity-removing elements into two quartz crucibles respectively, connect the two crucibles and then evacuate and heat the quartz crucibles until the vacuum degree reaches 1×10 -4 torr, the end of the quartz crucible is gradually sealed by melting with an oxyhydrogen flame.

[0057] 3. Sintering and impurity removal:

[0058] Put the sealed quartz c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com