Surface treatment copper foil and surface treatment method as well as laminated circuit basal board

A surface treatment layer and surface treatment technology, applied in the direction of circuit substrate materials, printed circuit components, chemical instruments and methods, etc., can solve the problems of improving the bonding strength between copper foil and polyimide, and achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

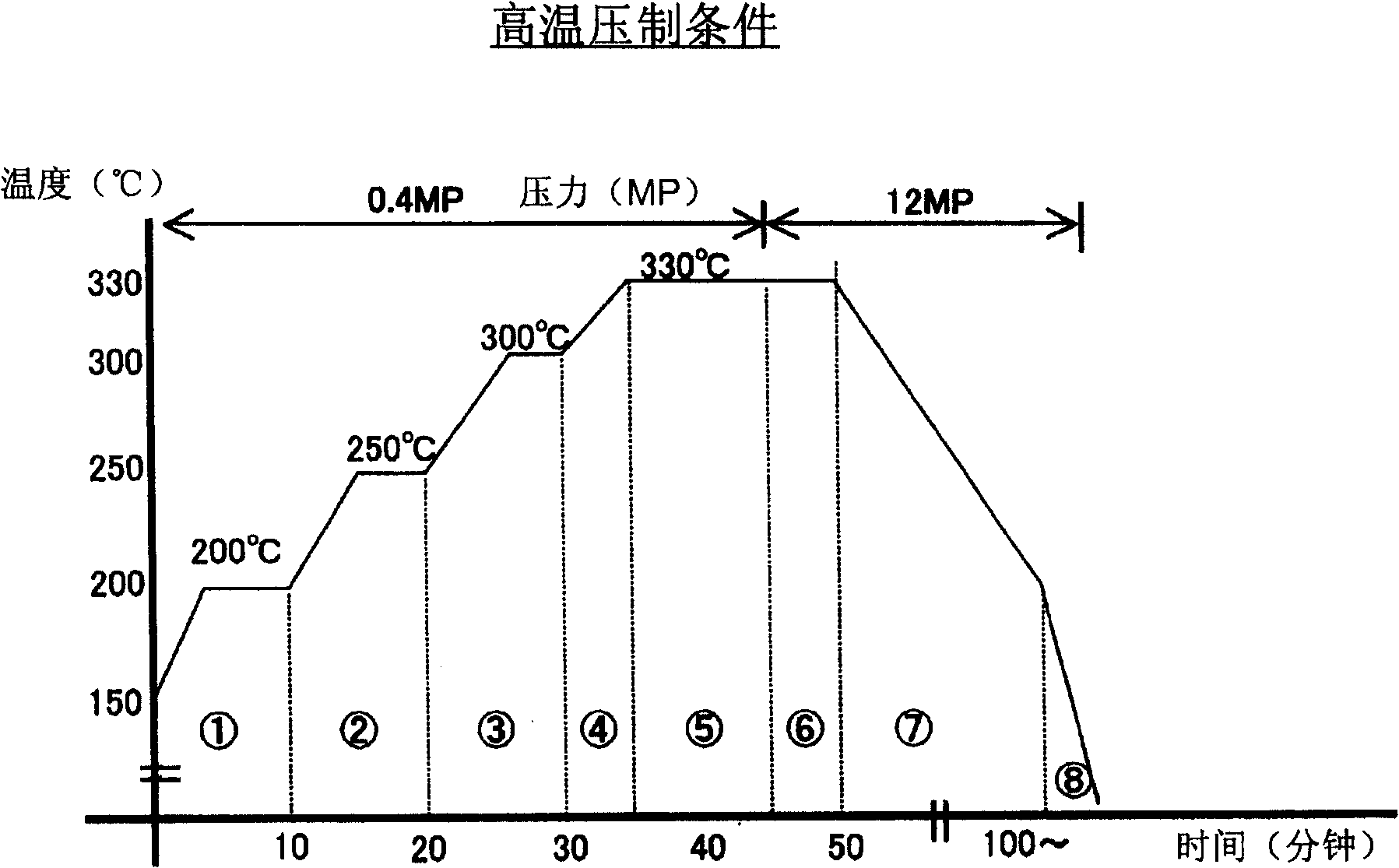

Method used

Image

Examples

Embodiment 1、2

[0039] Add NaH under the conditions to achieve 0.6g / L in terms of P metal content 2 PO 2 ·H 2 o

[0040] Add ZnSO under the condition of 0.5g / L in terms of Zn metal component 4 ·7H 2 o

[0041] As other ingredients, add 1.0g / L H 3 BO 3

[0042] Bath temperature: 45°C

[0043] pH: 3.5

[0044] Current density: 0.5A / dm 2

[0045] Processing time: 10 seconds

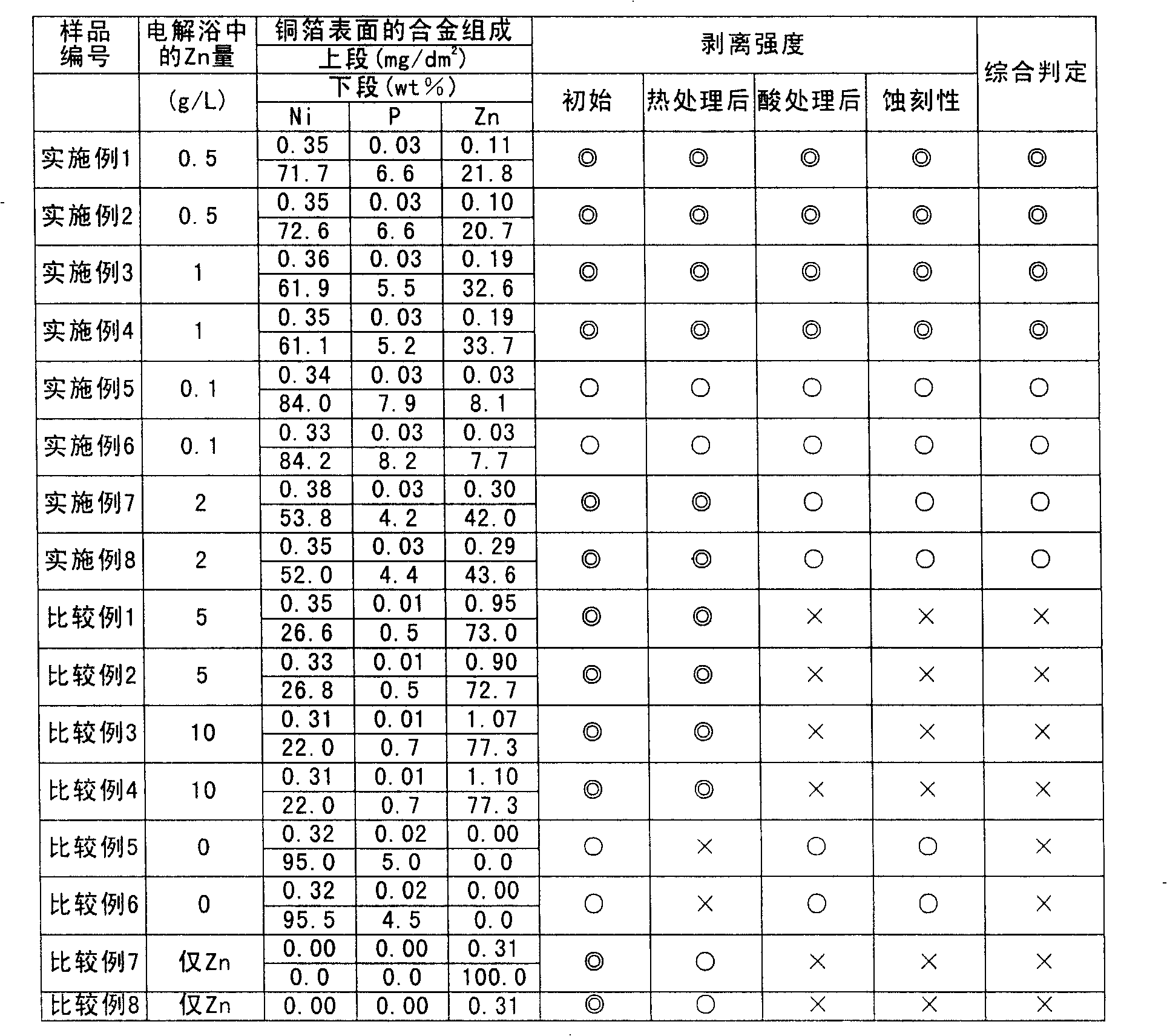

[0046] Surface treatment was performed twice on the above-mentioned untreated copper foil with the electrolytic bath of the above-mentioned composition and its conditions. As Example 1 for the first time and Example 2 for the second time, the following measurements were performed on the surface-treated copper foil, and the measurement results are shown in Table 1 as Examples 1 and 2.

[0047] (1) Alloy composition of the surface treatment layer deposited on the surface of the copper foil: analyzed by fluorescent X-rays.

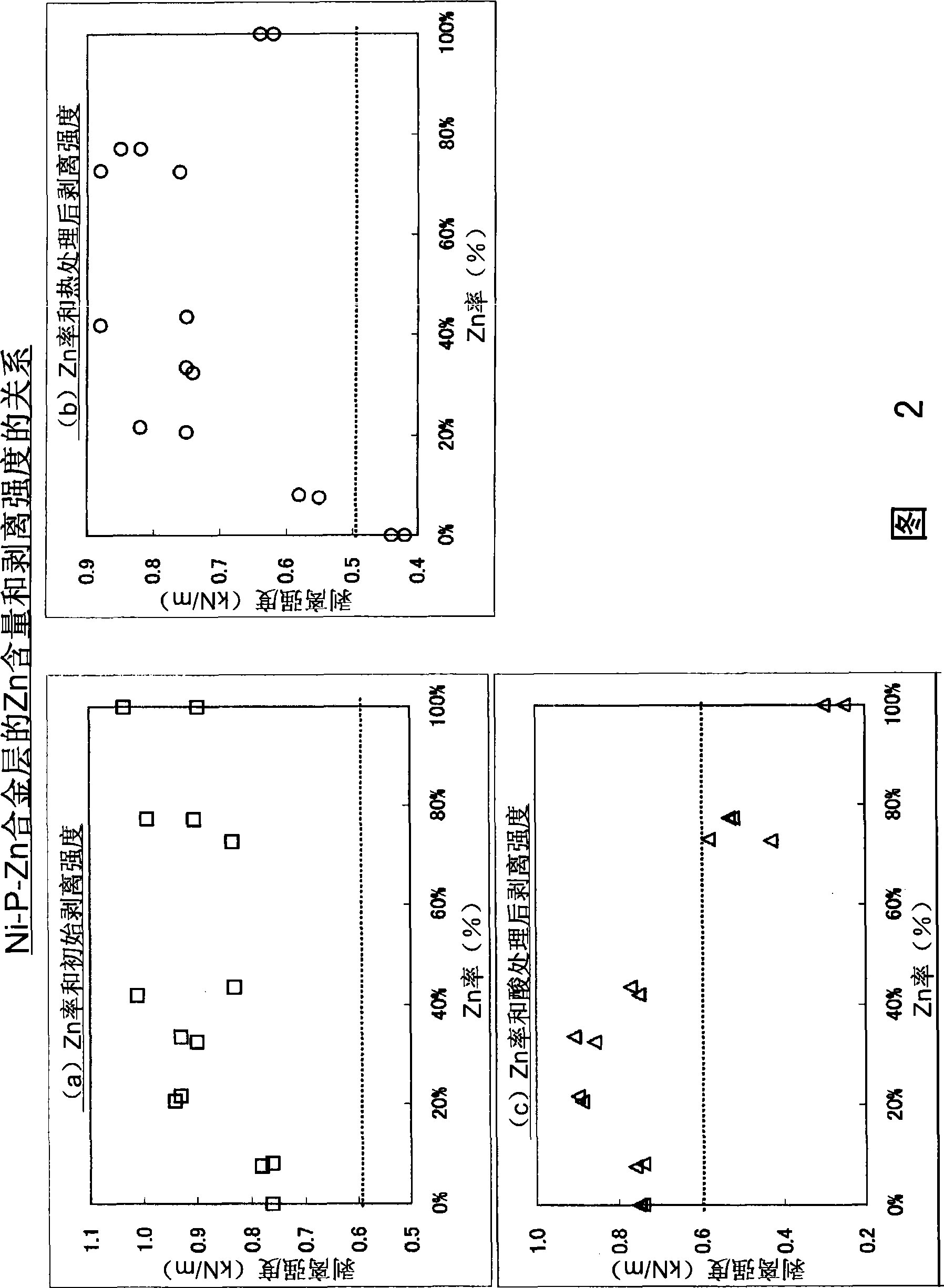

[0048] (2) Initial peel strength: The surface-treated copper foil in Examples 1 and 2 was b...

Embodiment 3、4

[0055] Add NaH under the conditions to achieve 0.6g / L in terms of P metal content 2 PO 2 ·H 2 o

[0056] Add ZnSO under the condition of 1.0g / L in terms of Zn metal component 4 ·7H 2 o

[0057] As other ingredients, add 1.0g / L H 3 BO 3

[0058] Bath temperature: 45°C

[0059] pH: 3.5

[0060] Current density: 0.5A / dm 2

[0061] Processing time: 15 seconds

[0062] Surface treatment was performed twice on the above-mentioned untreated copper foil with the electrolytic bath of the above-mentioned composition and its conditions. The same measurement as Example 1 was performed about the surface-treated copper foil, and the first time was made into Example 3, and the second time was made into Example 4, and the results are shown in Table 1 as Examples 3 and 4.

[0063]

[0064] Copper foil (untreated copper foil): WZ copper foil of Furukawa Circuit Copper Foil Co., Ltd., Rz: 1.0

Embodiment 5、6

[0066] Add NaH under the conditions to achieve 0.6g / L in terms of P metal content 2 PO 2 ·H 2 o

[0067] Add ZnSO under the condition of 0.1g / L in terms of Zn metal component 4 ·7H 2 o

[0068] As other ingredients, add 1.0g / L H 3 BO 3

[0069] Bath temperature: 45°C

[0070] pH: 3.5

[0071] Current density: 0.5A / dm 2

[0072] Processing time: 4 seconds

[0073] Surface treatment was performed twice on the above-mentioned untreated copper foil with the electrolytic bath of the above-mentioned composition and its conditions. The same measurement as in Example 1 was performed on the surface-treated copper foil, and the first time was taken as Example 5, and the second time was taken as Example 6. The results are shown in Table 1 as Examples 5 and 6.

[0074]

[0075] Copper foil (untreated copper foil): WZ copper foil of Furukawa Circuit Copper Foil Co., Ltd., Rz: 1.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com