Film forming method and film forming apparatus

A film-forming method and a film-forming device technology, which are applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve problems such as increased maintenance frequency, and achieve the effect of inhibiting the mixing of impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

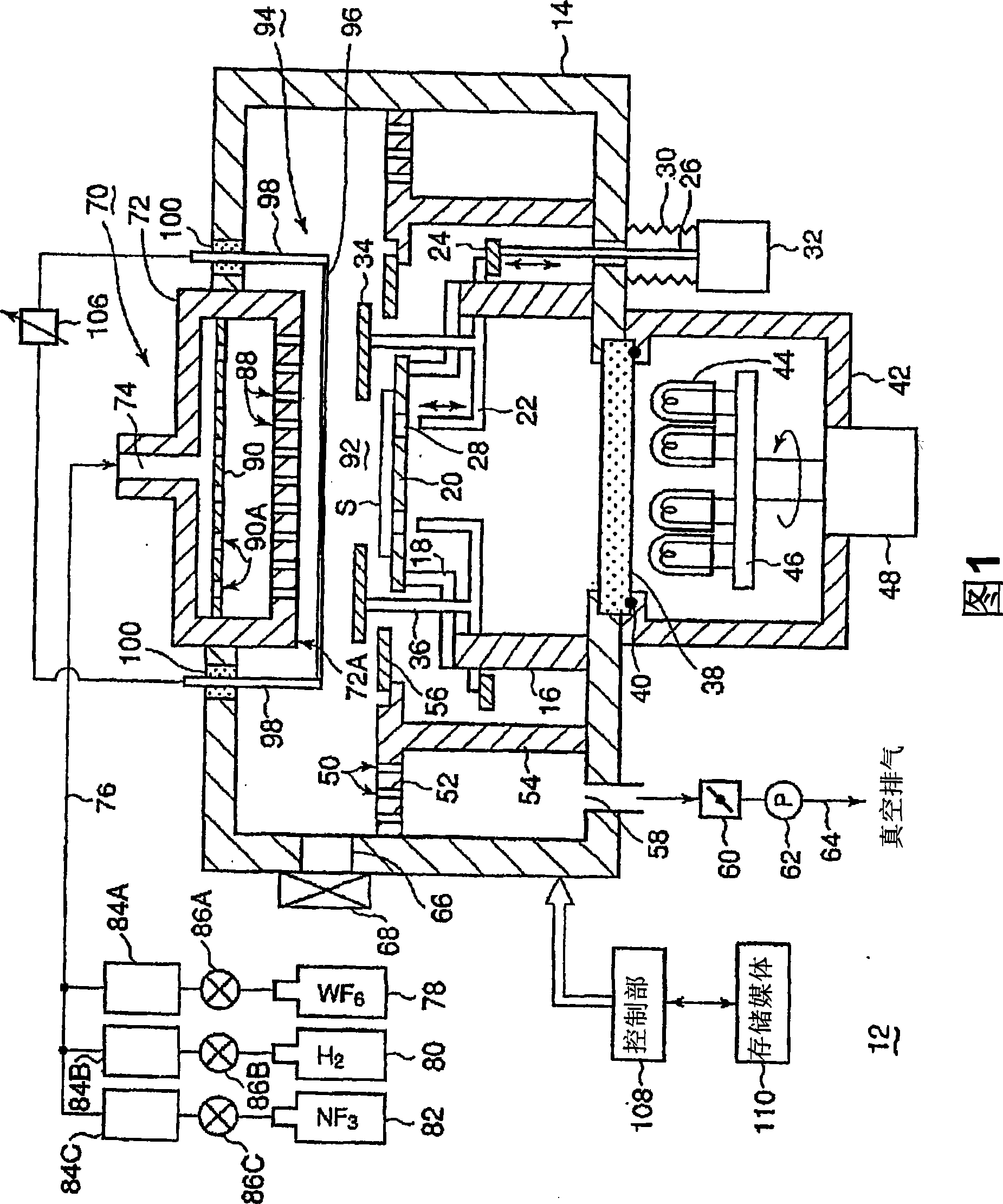

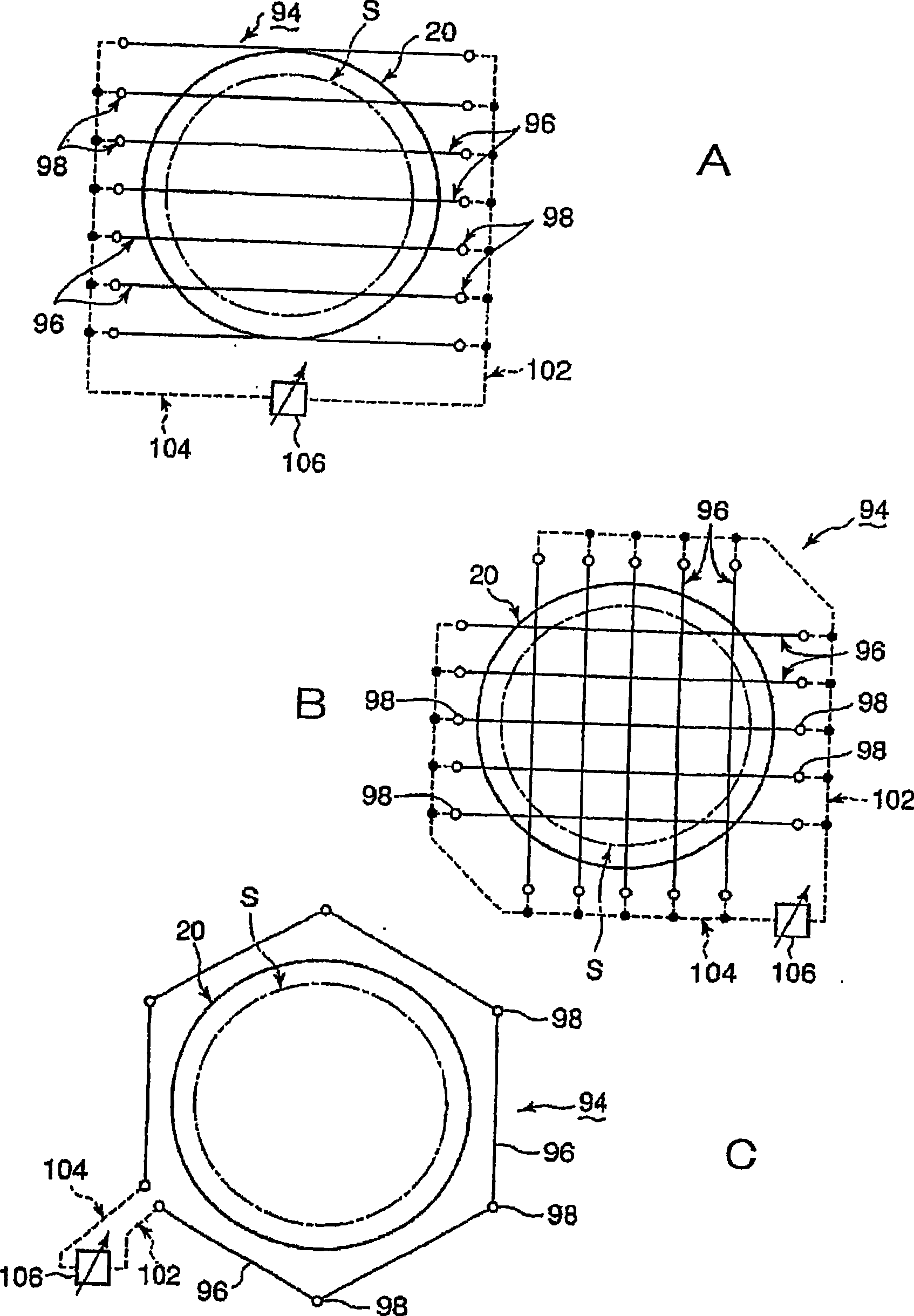

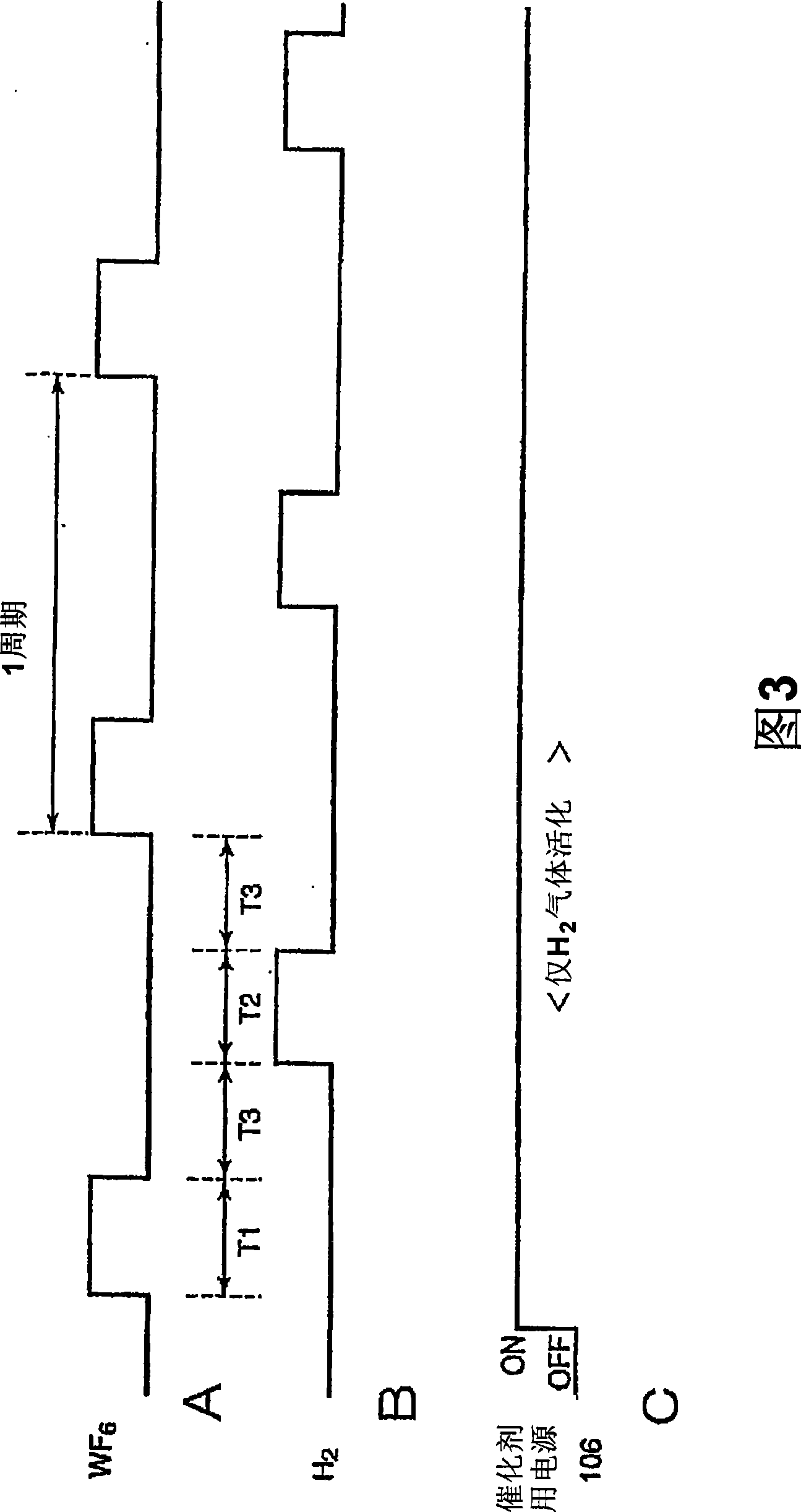

[0043]FIG. 1 is a schematic configuration diagram showing a first embodiment of a film forming apparatus of the present invention. figure 2 A~ figure 2 C is a plan view showing an arrangement example of catalyst bodies, respectively. The film forming apparatus 12 of this embodiment is an apparatus for forming a tungsten (W) film.

[0044] As shown in FIG. 1 , the film forming apparatus 12 has a cylindrical or box-shaped processing container 14 made of, for example, an aluminum alloy or the like. Inside the processing container 14 are provided a pillar 16 rising from the bottom of the container, and a mounting table 20 provided on the pillar 16 via a holding member 18 having, for example, an L-shaped cross section. A semiconductor wafer S as an object to be processed is placed on the stage 20 . The pillar 16 and the holding member 18 are made of a heat-ray transparent material such as quartz. In addition, the mounting base 20 is made of a carbon material, an aluminum comp...

no. 2 approach

[0085] In the first embodiment described above, the case where the tungsten film is formed has been described as an example, but the present invention is also applicable to the case where the tungsten nitride film (WN) is formed instead of the tungsten film.

[0086] In this case, in the film forming apparatus shown in FIG. 1 , a nitriding gas may be used instead of a reducing gas. Specifically, without setting storage H 2 Instead, a nitriding gas source (not shown) for storing nitriding gas is provided instead. In this case, N can be used 2 gas as a nitriding gas. Here, if the N used for purging is used directly 2 gas, there is no need to separately set up a nitriding gas source.

[0087] In this case, the deposited film type is changed from a tungsten film to a tungsten nitride film. Others exhibit the same effects as those described in the first embodiment. That is, in the second embodiment, instead of using the reducing gas, only the nitriding gas, that is, N 2 Gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com