Logistic storage type tridimensional bin/garage

A warehouse-style, three-dimensional technology, applied in the field of warehouses/garages, can solve the problems of low effective space utilization, long time for accessing vehicles, and low work efficiency, so as to save the area of the warehouse, improve work efficiency, and improve land use. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

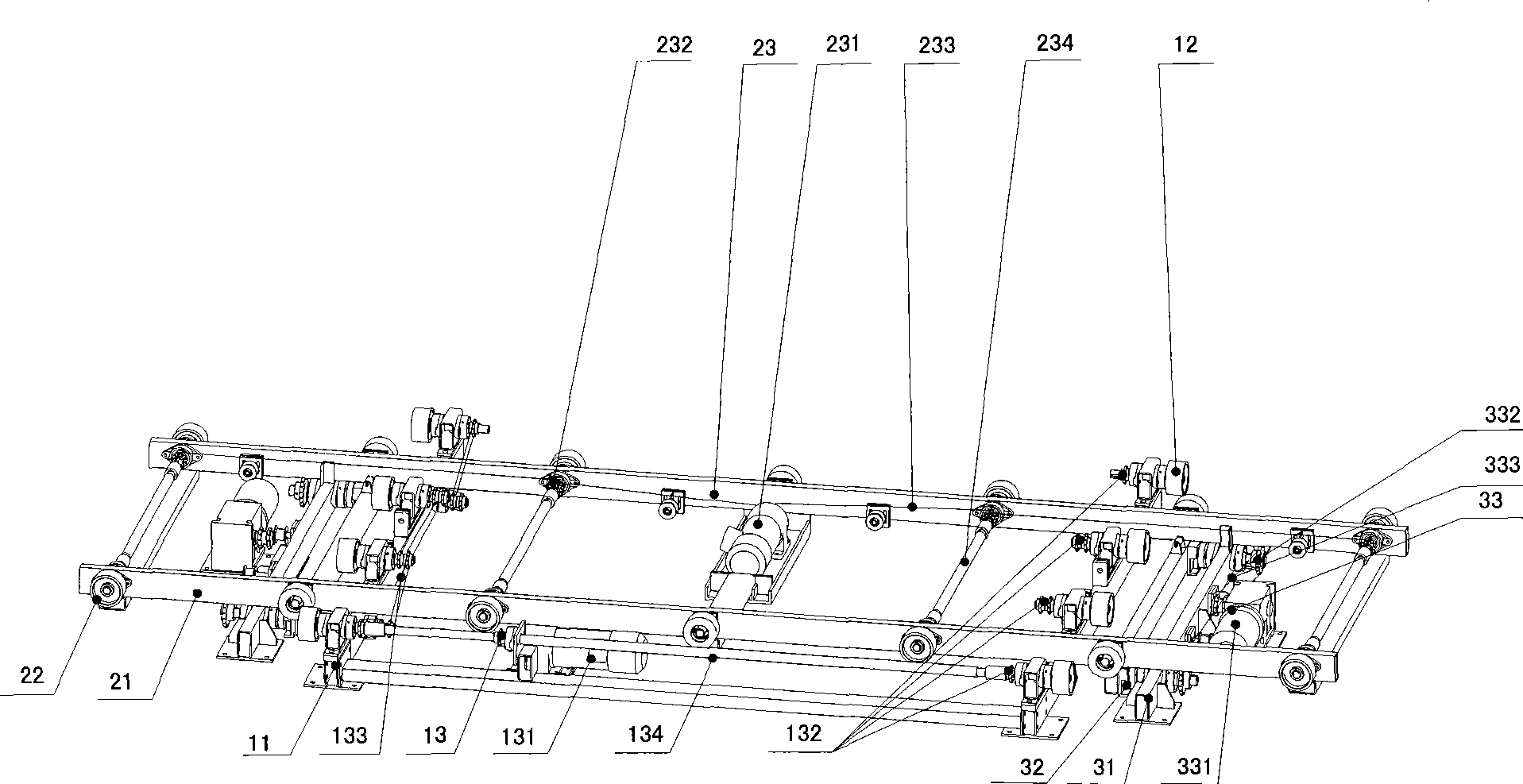

[0019] The logistics storage type three-dimensional warehouse / garage of the present invention comprises a storeroom with a multi-storey structure, a plurality of trays for carrying articles and elevators for vertically conveying trays between layers, and each floor of the storehouse is provided with multiple The conveyor that transports the pallet to the designated berth has two parking units on each side of each conveyor, and each parking unit has at least two rows of parking berths; the conveyor is installed on the elevator. Each conveyor is equipped with a longitudinal movement mechanism, a lateral movement mechanism and a vertical micro-lift mechanism. The lateral movement mechanism can drive the tray to realize lateral movement. The longitudinal movement mechanism can drive the tray to realize longitudinal movement. The vertical micro-lift mechanism can make the parking surface of the pallet set on the transfer machine less than 29cm from the ground after the vertical mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com