Non-aqueous electrolytic solution for lithium ion secondary battery and manufacturing method thereof

A non-aqueous electrolyte and secondary battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of reduced battery charge and discharge performance, low lithium ion conductivity, etc., and achieve improved cycle performance, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] a) The three refined solvents ethylene carbonate (EC), gamma-butyrolactone (GBL), and ethyl methyl carbonate (EMC) are mixed uniformly in a weight ratio of 1:1:1, and the quality of the carbonate solution obtained is 880 grams;

[0038] b) Slowly add 120 g of 1M LiPF 6 , so that it is completely dissolved to form a basic anhydrous electrolyte;

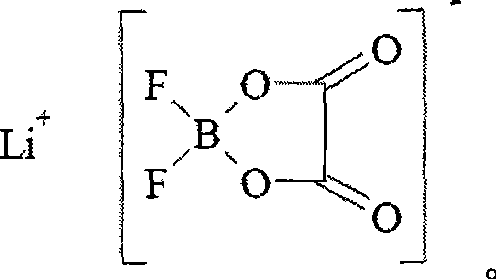

[0039] c) Add 2.0% of 1,3-propane sultone and 0.5% of lithium oxalyl difluoroborate composition additive to the basic anhydrous electrolyte, stir ultrasonically and mix evenly to obtain a colorless and transparent non-aqueous electrolytic solution Liquid, colorless and transparent non-aqueous electrolyte by 100%.

[0040] Electrolyte performance test: In order to strictly control the moisture and acidity of the electrolyte, the obtained electrolyte was injected into a 18650 cylindrical lithium-ion secondary battery in a Braun glove box, and the positive electrode was spinel lithium manganate (LiMn 2 o 4 ) material and the ne...

Embodiment 2

[0054] a) four refined solvents EC, DMC, EMC, and propylene carbonate PC are mixed uniformly in a weight ratio of 0.8:1:1:0.2 to obtain 880 grams of carbonate;

[0055] b) Slowly add 1.1M LiPF 6 132 grams to make it completely dissolved to form a basic anhydrous electrolyte;

[0056] c) Add 1.0% 1,3-propane sultone and 1.0% lithium oxalyl difluoroborate additives to the basic anhydrous electrolyte, stir ultrasonically and mix evenly to obtain a colorless and transparent non-aqueous Electrolyte, colorless and transparent non-aqueous electrolyte is calculated as 100%.

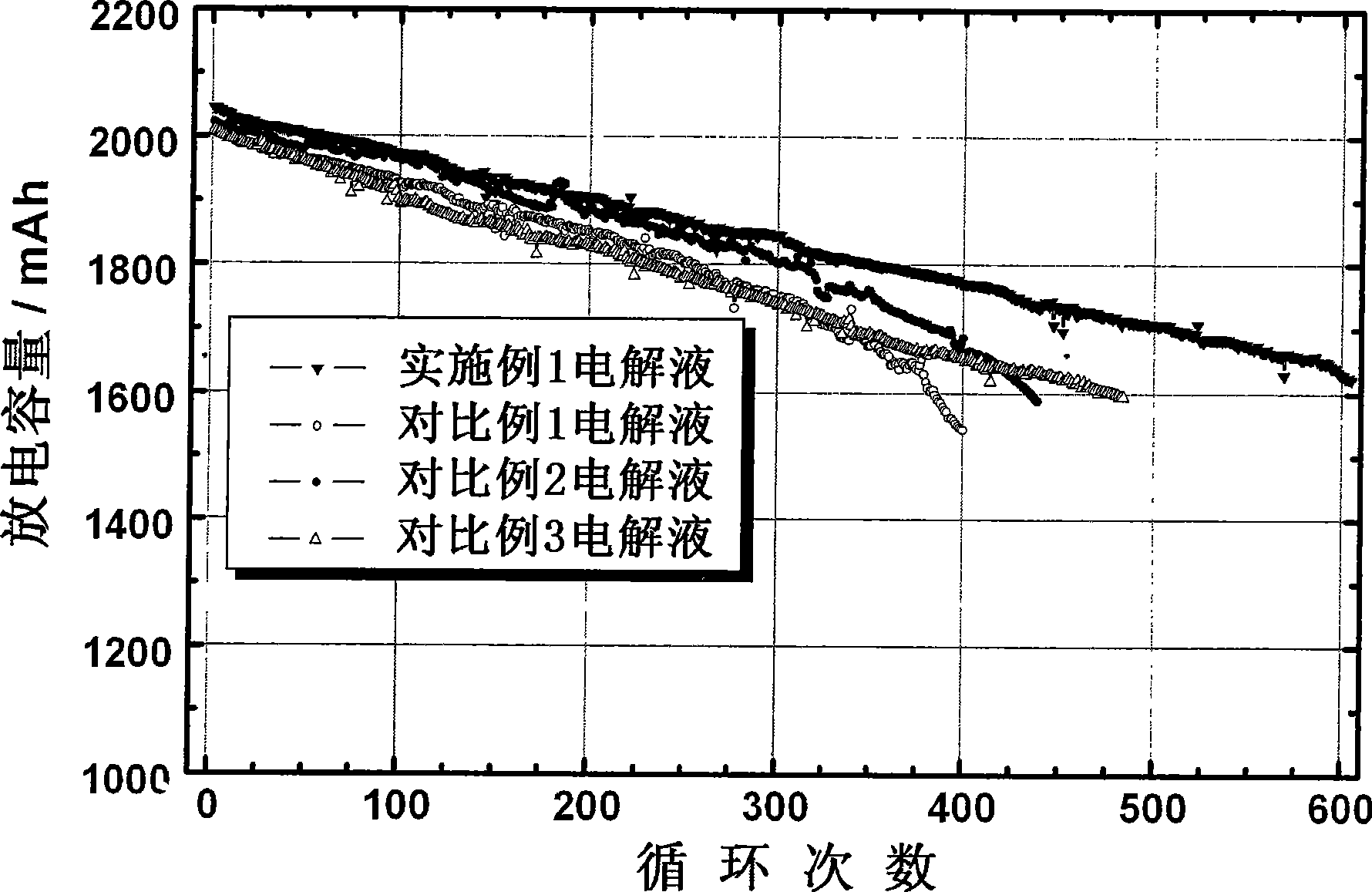

[0057] Inject the obtained electrolyte solution into a 18650-type cylindrical lithium-ion secondary battery in a Braun glove box. Formation, cycle performance test, the cycle performance of battery is shown in Table 2 and figure 1 . Table 1 compares the safety performance (weight impact test) of the steel case battery manufactured according to this embodiment with the steel case battery of Example 1 and Compa...

Embodiment 3

[0061] a) The refined four solvents EC, DMC, EMC, and DEC are uniformly mixed in a weight ratio of 0.8:1:1:0.2 to obtain 880 grams of carbonate;

[0062] b) Slowly add 1.2M LiPF 6 , 144 grams, so that it is completely dissolved to form a basic anhydrous electrolyte;

[0063] c) Add 1.6% vinylene carbonate, 1.5% 1,3-propane sultone, and 1.5% lithium oxalyl difluoroborate additives in sequence, and mix evenly. The mixed electrolyte is as follows: 100% meter.

[0064] Inject the obtained electrolyte solution into a 18650-type cylindrical lithium-ion secondary battery in a Braun glove box. Formation and cycle performance test, the cycle performance of the battery is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com