Li2O-Al2O3-SiO2-based crystallized glass

A technology of crystallized glass and crystalline glass, applied in the field of Li2O-Al2O3-SiO2 series crystallized glass, can solve the problem of taking a long time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The crystallized glass of the present invention will be described in detail using examples and comparative examples.

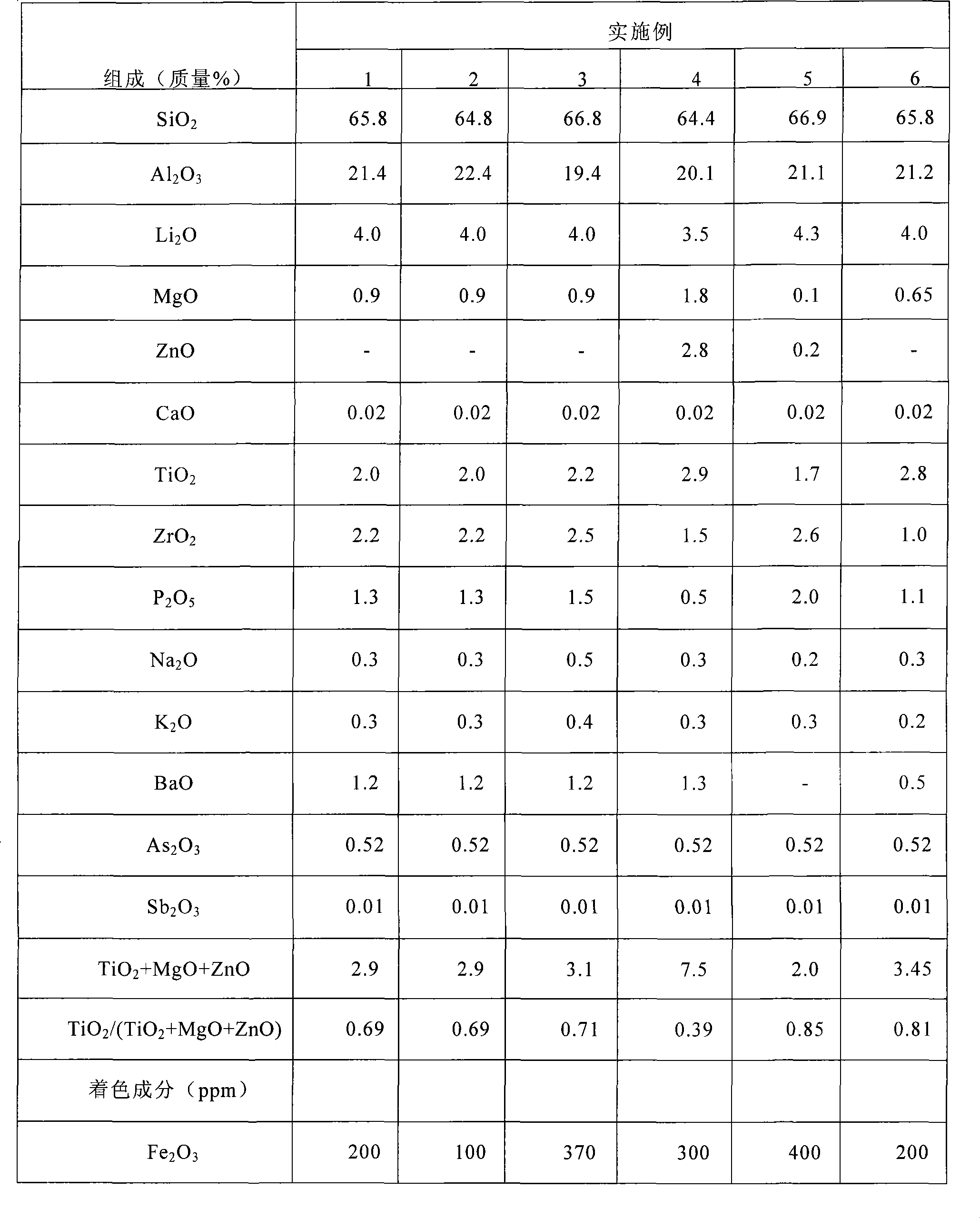

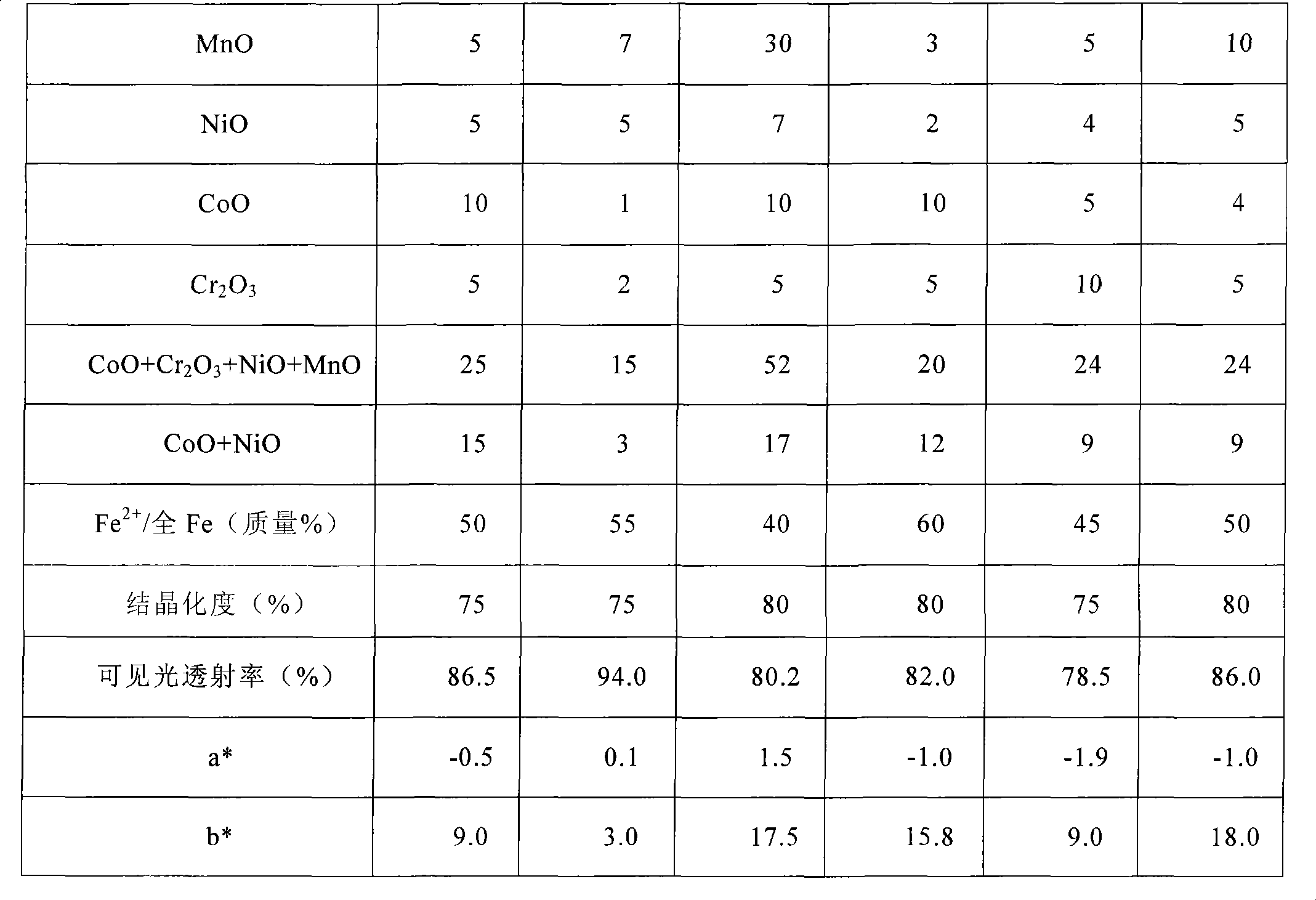

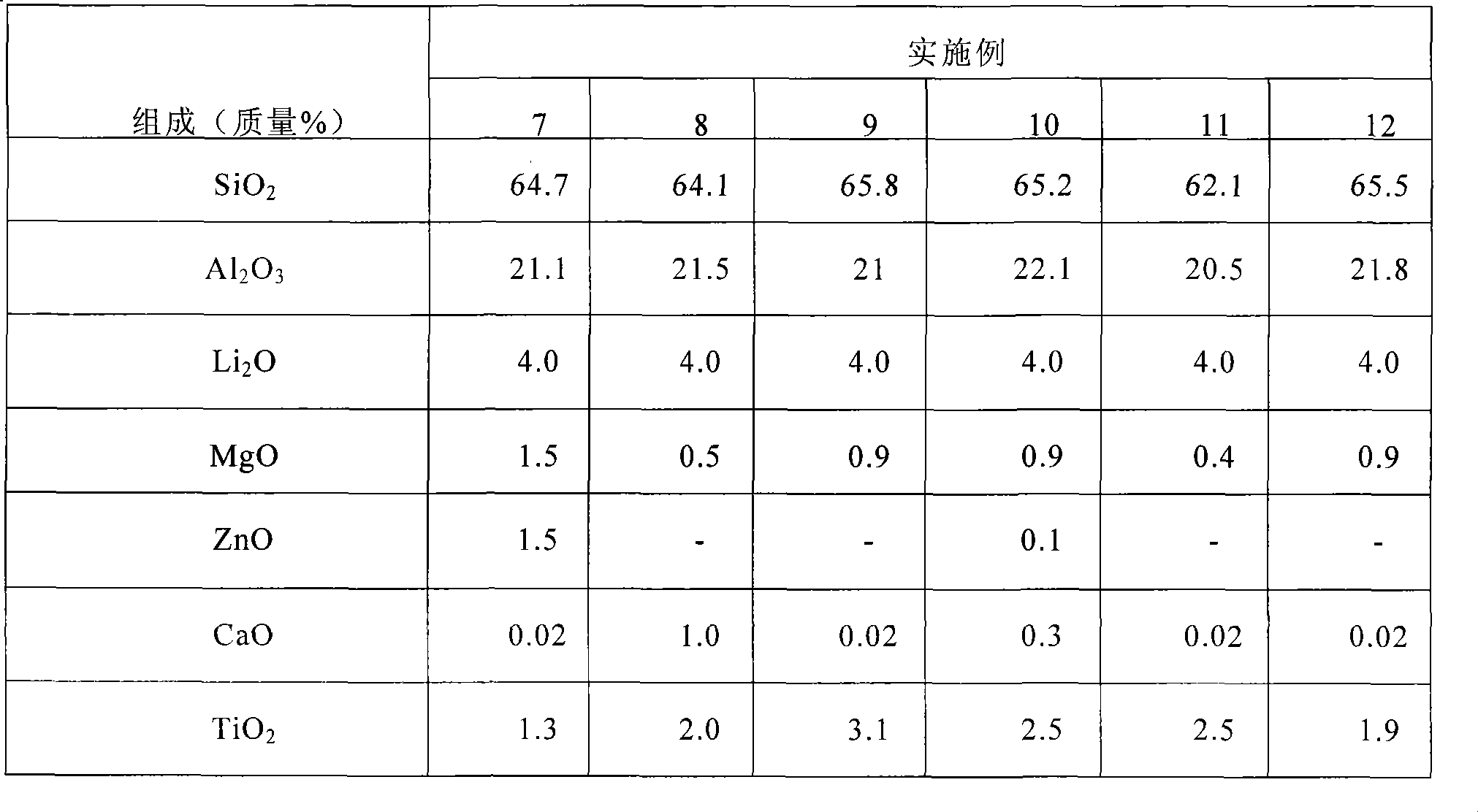

[0048] Table 1 shows Examples 1-6 of the present invention, Table 2 shows Examples 7-12, and Table 3 shows Comparative Examples 1-6.

[0049] [Table 1]

[0050]

[0051] [Table 1] (continued)

[0052]

[0053] [Table 2]

[0054]

[0055] [Table 21] (continued)

[0056]

[0057] [table 3]

[0058]

[0059] [Table 3] (continued)

[0060]

[0061] First, prepare glass raw materials containing nitrates of sodium, potassium, and barium according to the compositions in each table, melt the prepared glass raw materials at 1550-1750°C for 4-40 hours, and then shape them to obtain Li 2 O—Al 2 o 3 —SiO 2 Department of crystallized glass. In addition, in Example 5, since BaO was not contained, the nitrate of barium was not used. In addition, in Comparative Example 6, a glass raw material containing 0.5% of carbon was used instead of a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com