Device and method for ultrasonic strengthening frozen dough

A technology for frozen dough and ultrasonic strengthening, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems such as no ultrasonic strengthening freezing dough device and method, and achieves shortening the total freezing time, simple operation and control, and improving the quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Self-designed and entrusted to process the ultrasonic device, the frequency of the selected ultrasonic device is 25KHz, the number of transducers is 10, the maximum peak electric power is 600W, the size of the ultrasonic tank is 330×330×230mm, the working time and intermittent time of the ultrasonic equipment are in 0-999s adjustable; the refrigeration cycle device can choose the Ministat CC1 thermal cycle device produced by Peter Huber Company in Germany, its working temperature range is -30 ° C ~ 200 ° C, the flow rate of the pump is adjustable from 2000 ~ 5000 r / min; scanning thermoelectric The dual thermometer can be selected from the Model 92000-05 scanning temperature recorder produced by Cole-Parmer in the United States, which has a nickel-chromium alloy thermocouple probe and can transmit the measured temperature data to the connected computer in real time; A PC with temperature monitoring software installed.

[0032] The nickel-chromium alloy thermocouple probe...

Embodiment 2

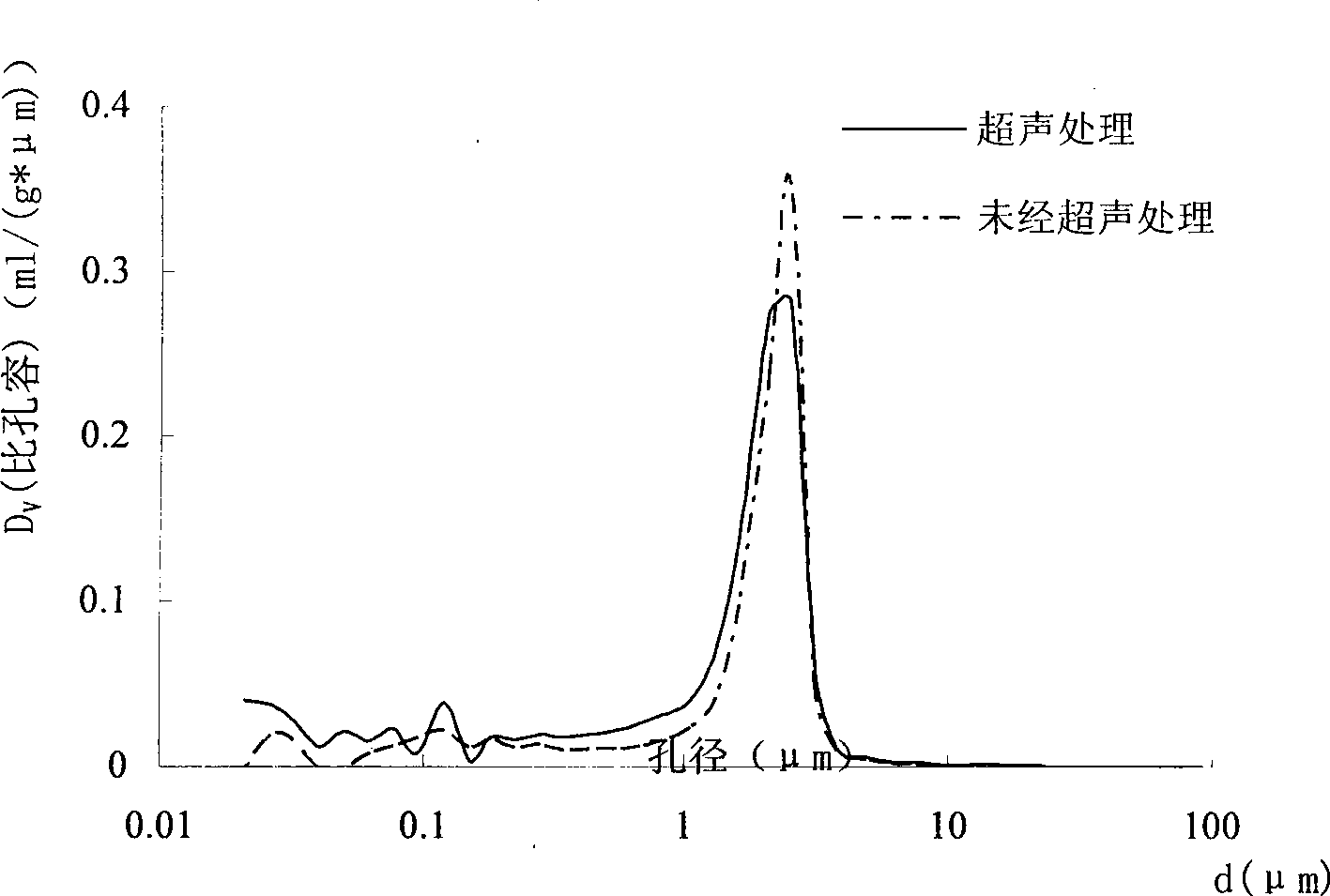

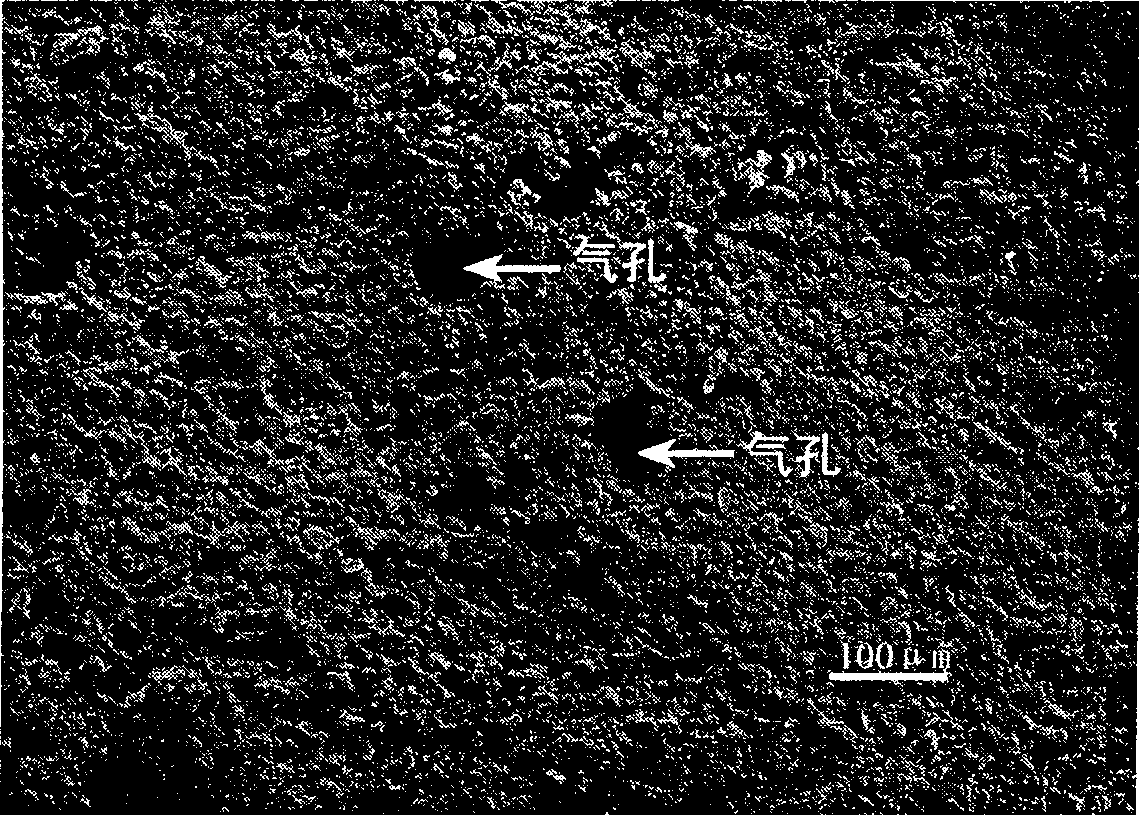

[0037] Using the ultrasonically strengthened frozen dough equipment of Example 1, take flour with a gluten content of 13.3% and a moisture content of 13.2%, add water until the moisture content is 67%, and form a cylindrical dough with a bottom diameter of 20 mm and a height of 40 mm. Application of ultrasound to strengthen frozen dough. Operating conditions: the starting temperature of the dough is 23.5°C, the freezing medium is 60% (v / v) ethylene glycol solution, the temperature of the freezing medium in the storage tank of the refrigeration cycle device is set at -22°C, the pump speed is 3500r / min, the control The temperature of the freezing medium in the ultrasonic tank is -21°C, the distance between the bottom of the cylindrical dough and the bottom of the ultrasonic tank is 5cm, the electric power of the ultrasonic waves is 0W (no ultrasonic effect), 224, 288W, 360W and 418W, and the duty ratio is 1:2. When the temperature of the center of the dough reaches -18°C, the fr...

Embodiment 3

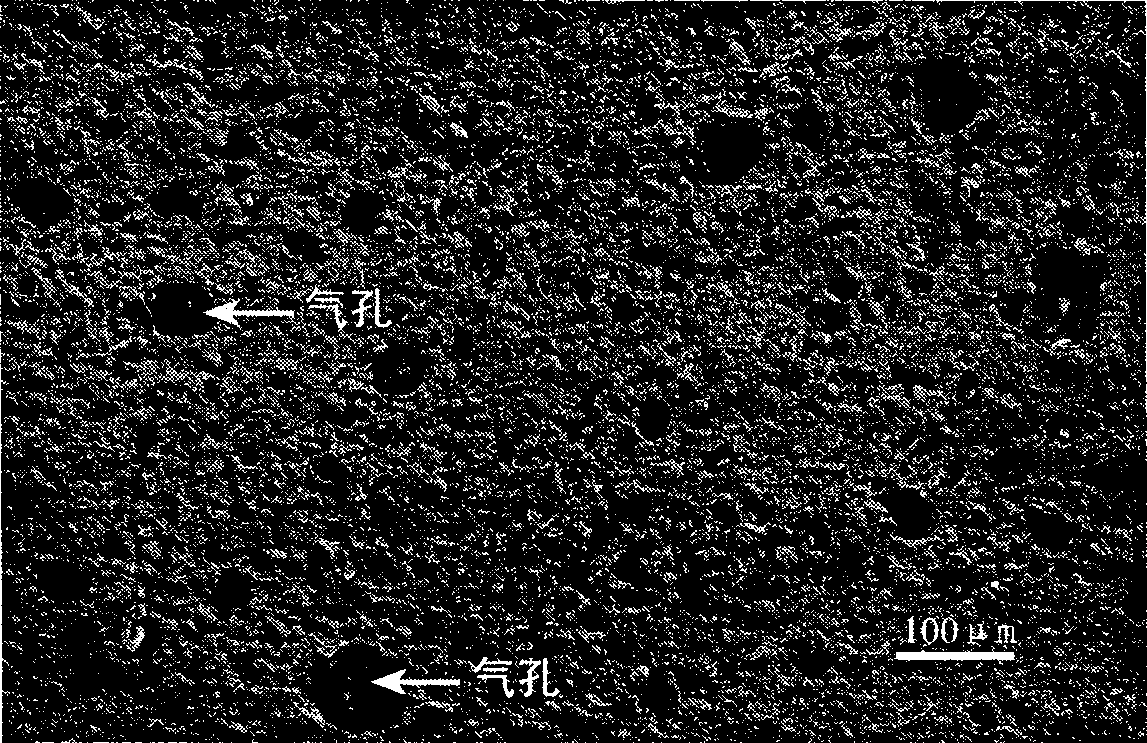

[0041] Using the ultrasonically strengthened frozen dough device of Example 1, take flour with a gluten content of 13.3% and a moisture content of 13.2%, add water until the moisture content is 67%, and form a cylindrical dough with a bottom diameter of 20 mm and a height of 40 mm. Application of ultrasound to strengthen frozen dough. Operating conditions: the starting temperature of the dough is 23.5°C, the freezing medium is 40% (v / v) ethylene glycol solution, the temperature of the freezing medium in the storage tank of the refrigeration cycle device is set at -23°C, the pump speed is 3000r / min, the control The temperature of the freezing medium in the ultrasonic tank is -20°C, the distance between the bottom of the cylindrical dough and the bottom of the ultrasonic tank is 4cm, the ultrasonic electric power is 360W, and the duty ratio is 1:3. When the central temperature of the dough reaches -18°C, the freezing is over. When the frozen dough obtained in this example is tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com