Chemical mechanical polishing method

A chemical-mechanical, dielectric layer technology, used in grinding devices, grinding machine tools, grinding/polishing equipment, etc., can solve problems such as short circuits, inability to be completely removed, affecting structural thickness and flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

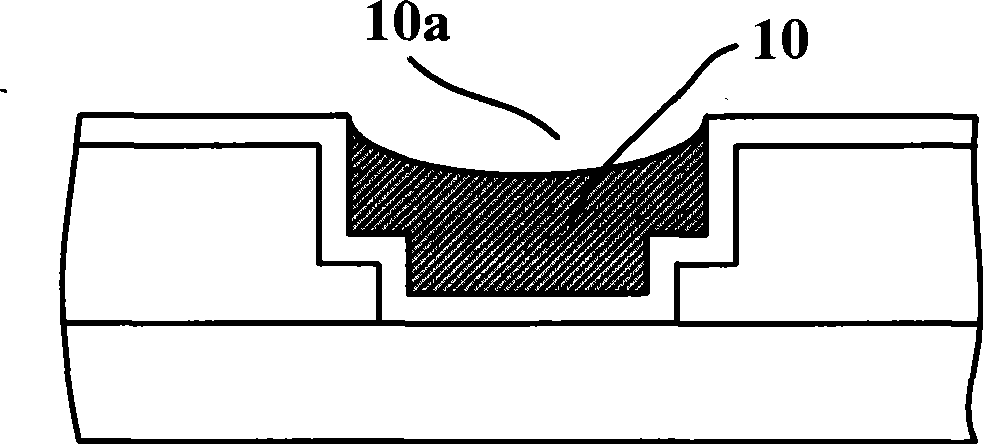

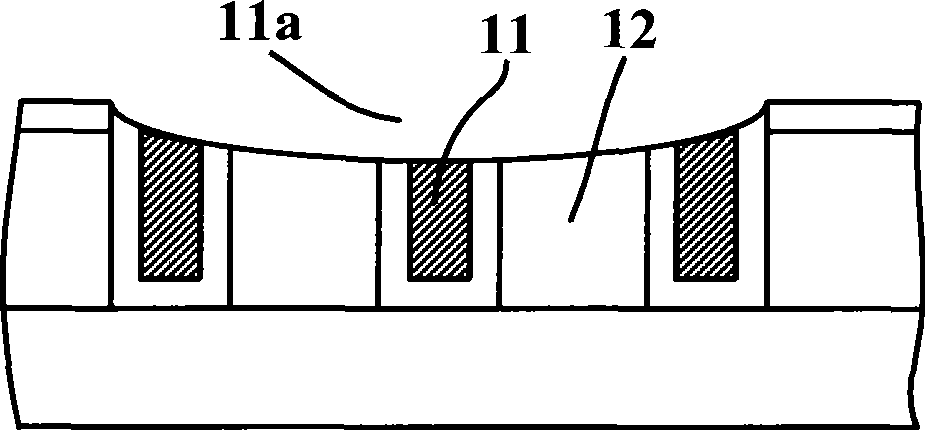

Image

Examples

Embodiment Construction

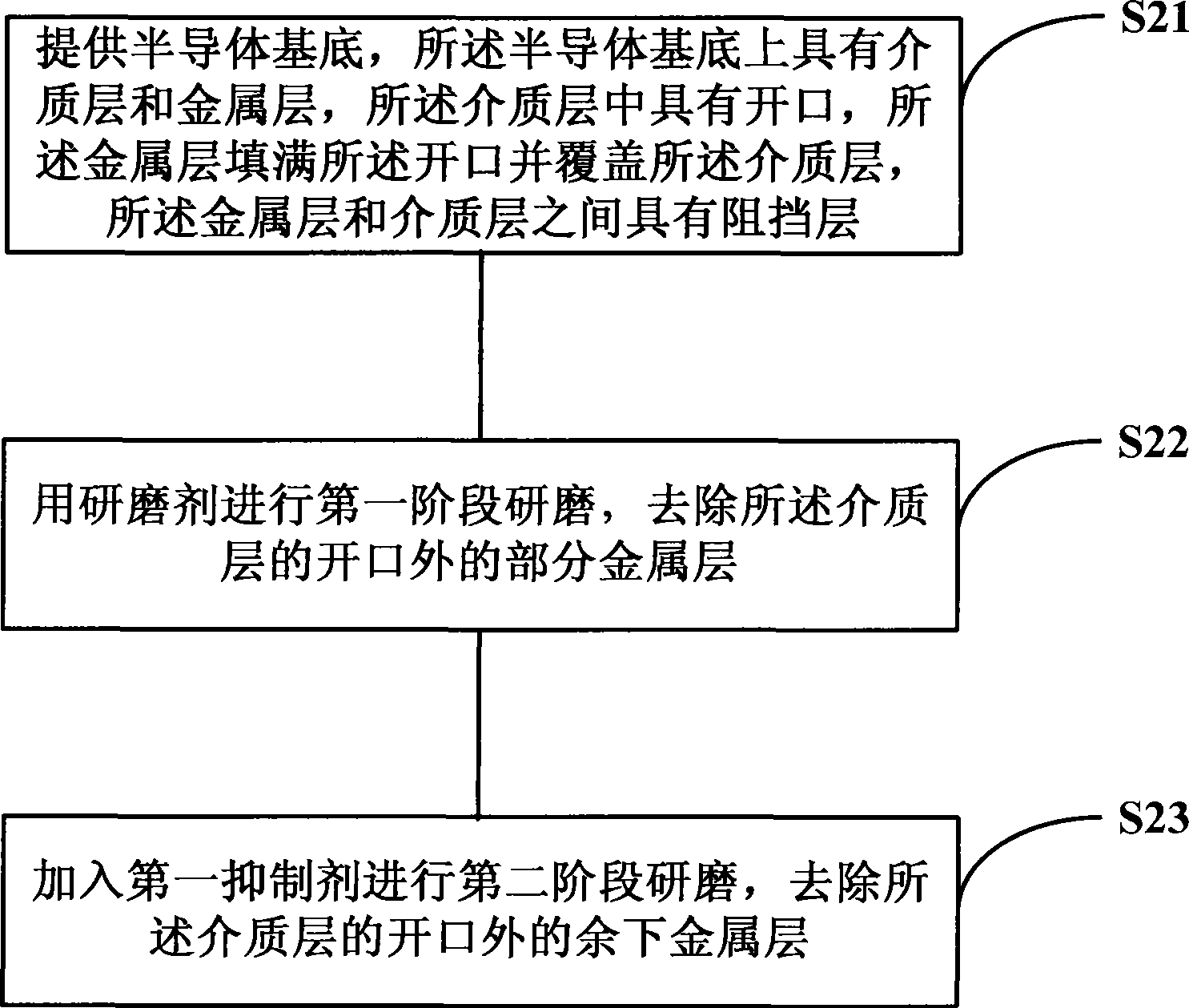

[0031] In the embodiment of the present invention, after grinding and removing most of the copper metal outside the opening of the dielectric layer of the semiconductor substrate, an inhibitor for delaying the copper grinding rate is added to continue grinding the semiconductor substrate to remove the remaining copper metal outside the opening. The dishing of the copper metal is also reduced because the copper metal grinds at a lower rate so that the copper grinds at a rate similar to that of its surrounding material.

[0032] The basic process of the method of chemical mechanical polishing in the embodiment of the present invention is as follows figure 2 shown, including the following steps:

[0033] Step S21, providing a semiconductor substrate, the semiconductor substrate has a dielectric layer and a metal layer, the dielectric layer has an opening, the metal layer fills the opening and covers the dielectric layer, the metal layer and the dielectric layer There is a barri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com