Alumina ceramic injection molding wax based polyethylene multi-polymer bonding agent method

An alumina ceramic and injection molding technology, which is applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult to prepare ceramic parts with small size, complex shape, size and precision, and limit the application field of ceramics, so as to reduce defects and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is illustrated below in conjunction with accompanying drawing.

[0026] The wax-based polyethylene polymer binder for alumina ceramic injection molding of the present invention is composed of paraffin, low-density polyethylene and stearic acid, and its component and volume ratio are: paraffin: low-density polyethylene: Stearic acid=60:20:14. .

[0027] Utilize the method for injection molding alumina ceramics of the above-mentioned wax-based polyethylene multipolymer binder for injection molding of alumina ceramics, comprising the following steps:

[0028] (1) Preparation of feed:

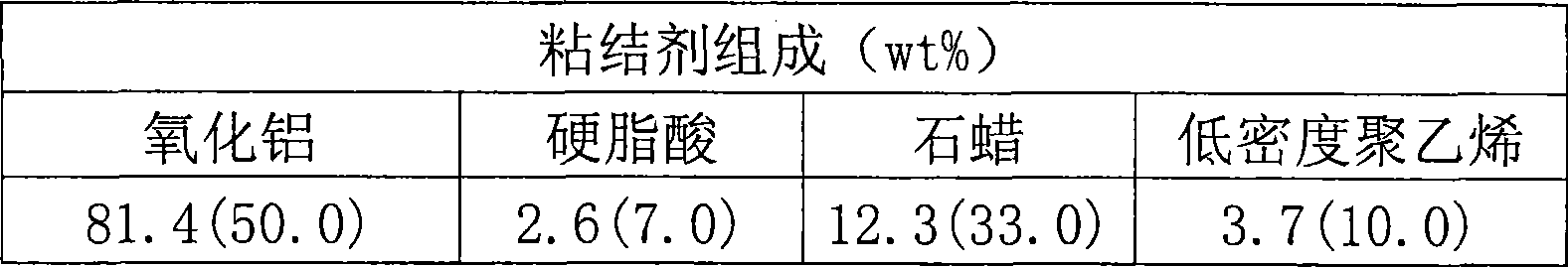

[0029] Mix and granulate the sinterable ceramic powder and the wax-based polyethylene polymer binder for alumina ceramic injection molding at a volume ratio of 1:1; see Table 3

[0030] Table 3 Composition of alumina binder mixture

[0031]

[0032] Note: in parentheses is the volume percentage

[0033] (2) Then carry out injection molding:

[0034] It is known...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com