Papaya sake and method for producing the same

A production method and technology of papaya, applied in the field of papaya sake and its production, can solve the problems of light taste, poor transparency, and easy precipitation, etc., and achieve the effects of improving edible value and nutritional value, preventing kidney stones, and outstanding fruity aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086] Embodiment: the present invention is made by the material of following weight ratio:

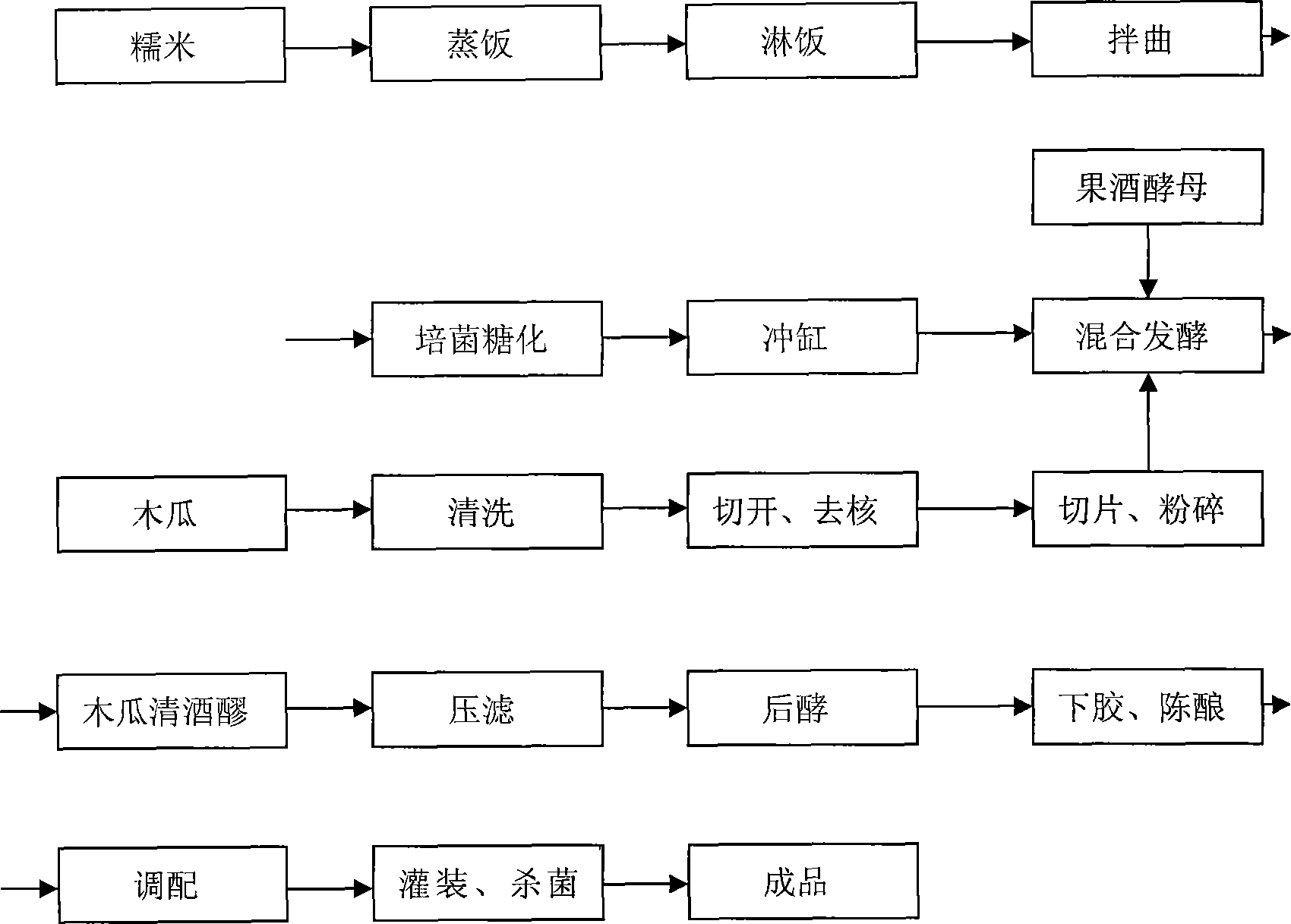

[0087] Glutinous rice is processed into sweet wine mash, crushed papaya puree and fruit wine yeast in a ratio of 1:1:1 and then fermented.

[0088] The production method that the present invention takes is:

[0089] 1) Steamed rice: Wash and soak the glutinous rice for 8 hours, then steam it with steam at 100°C for 30 minutes until it is cooked and not sticky or loose;

[0090] 2) Drain the rice: pour the steamed rice with pure water and cool to 30°C;

[0091] 3) Mixing koji: Sprinkle finely ground koji evenly into the rice, the ratio of the amount of koji to the rice is 0.8:100;

[0092] 4) Cultivation and saccharification: Pour the rice mixed with Xiaoqu into a vat and incubate at room temperature (not exceeding 28°C) for 3 days until the saccharification juice oozes out;

[0093] 5), vat flushing: Pour the same volume of pure water into the above vat to obtain sweet wine mash; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com