Fore treatment method of polyester-cotton fabric by high efficiency refining enzyme one-step and one-bath method

An enzyme-refining and high-efficiency technology, applied in fiber treatment, biochemical fiber treatment, plant fiber, etc., can solve the problems of high pre-treatment process consumption, short process flow, low comprehensive cost, etc., to reduce the pressure of sewage treatment, feel good, The effect of less gram weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

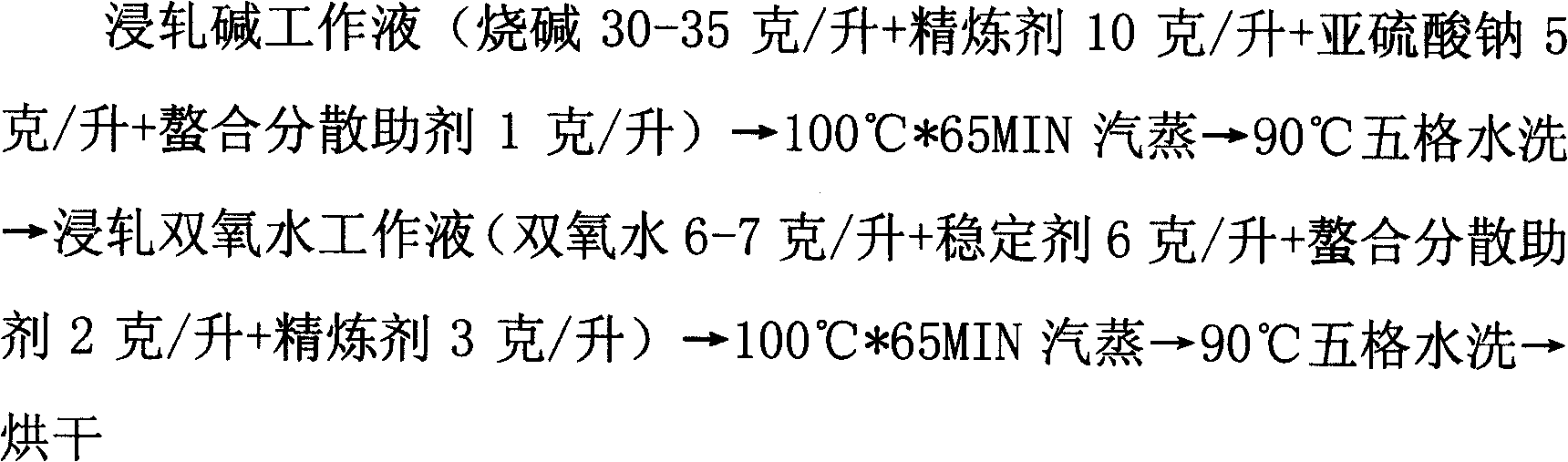

Method used

Image

Examples

Embodiment 1

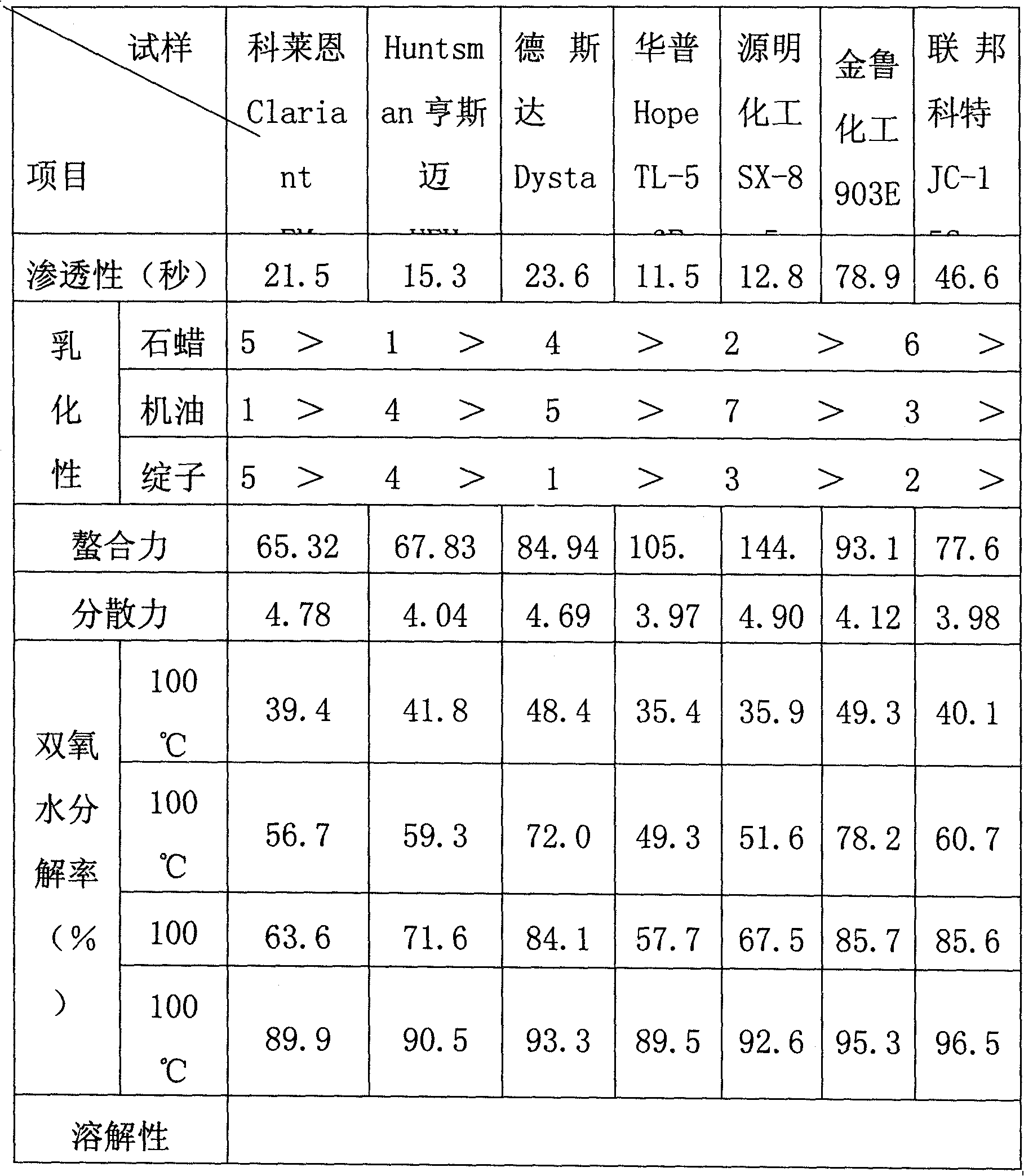

[0021] Selection of raw material refining enzymes:

[0022] The performance of refining enzyme directly affects the quality of pre-treatment semi-finished products, such as: hair effect, whiteness, strength, grammage, cloth surface effect, and indirectly affects the vividness, color yield, and color fastness of dyed and printed products. Uniformity of cloth surface. Therefore, the selection of scouring enzyme must consider its permeability, emulsification, chelating power, dispersing power, H 2 o 2 stability.

[0023] Permeability: The canvas sedimentation method is used for detection, and it is required to be within 10S to ensure that the liquid-carrying rate of the fabric after immersion is 80-100%;

[0024] Emulsification: The level of emulsification directly affects the level of fabric wool effect and the uniform dyeing property of the cloth surface, and the emulsification power of paraffin wax, spindle oil and machine oil is evaluated respectively;

[0025] Chelating ...

Embodiment 2

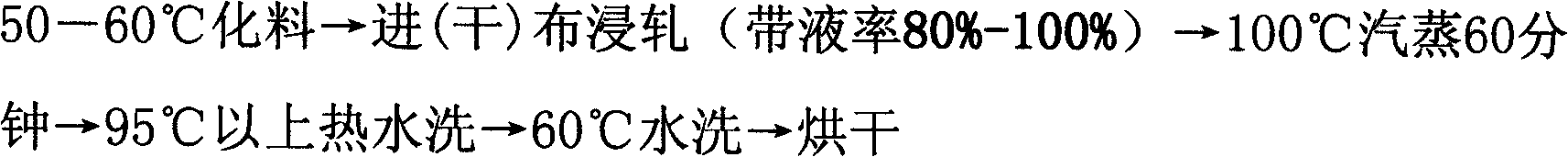

[0051] The polyester-cotton fabric adopts the pretreatment method of high-efficiency refining enzyme step-one-bath method. The following working solution is used to heat up the chemical material at 55°C, and then the dry cloth of the fabric to be treated is sent into the working solution for padding. 100%, then steamed at a high temperature of 98°C for 75 minutes, then washed with hot water above 98°C and washed twice with water at 65°C, and then dried to complete the one-step-one-bath pretreatment. The specific ratio of the working fluid is:

[0052] Hydrogen peroxide (100%) 12 g / L;

[0053] High-efficiency refining enzyme 28 g / L;

[0054] Refined penetrant 6 g / l.

[0055] Dye the fabric pre-treated by SX-85 high-efficiency refining enzyme one-step new process, and compare the physical performance indicators of the fabric with the products of the traditional pre-treatment process.

Embodiment 3

[0057]The polyester-cotton fabric adopts the pretreatment method of high-efficiency refining enzyme step-one-bath method. The following working solution is used to heat up the chemical material at 60°C, and then the dry cloth of the fabric to be treated is sent into the working solution for padding. 80%, then steamed at a high temperature of 102°C for 70 minutes, then washed with hot water above 96°C and washed twice with water at 60°C, and then dried to complete the one-step-one-bath pretreatment. The specific ratio of the working fluid is:

[0058] Hydrogen peroxide (100%) 14 g / L;

[0059] High-efficiency refining enzyme 26 g / L;

[0060] Refined penetrant 8 g / l.

[0061] The fabrics pre-treated by SX-85 high-efficiency refining enzyme one-step new process were printed, and the physical performance indicators of the fabrics were compared with the products of traditional pre-treatment processes.

[0062] Embodiment 2-3 gained product and traditional product comparison data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com