Sleeper synthesized by enhanced fiber

A technology for reinforcing fibers and sleepers, which is applied in the field of sleepers, can solve problems such as uneven durability, poor insulation performance, and lack of resources, and achieve the effects of easy molding, simple production, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

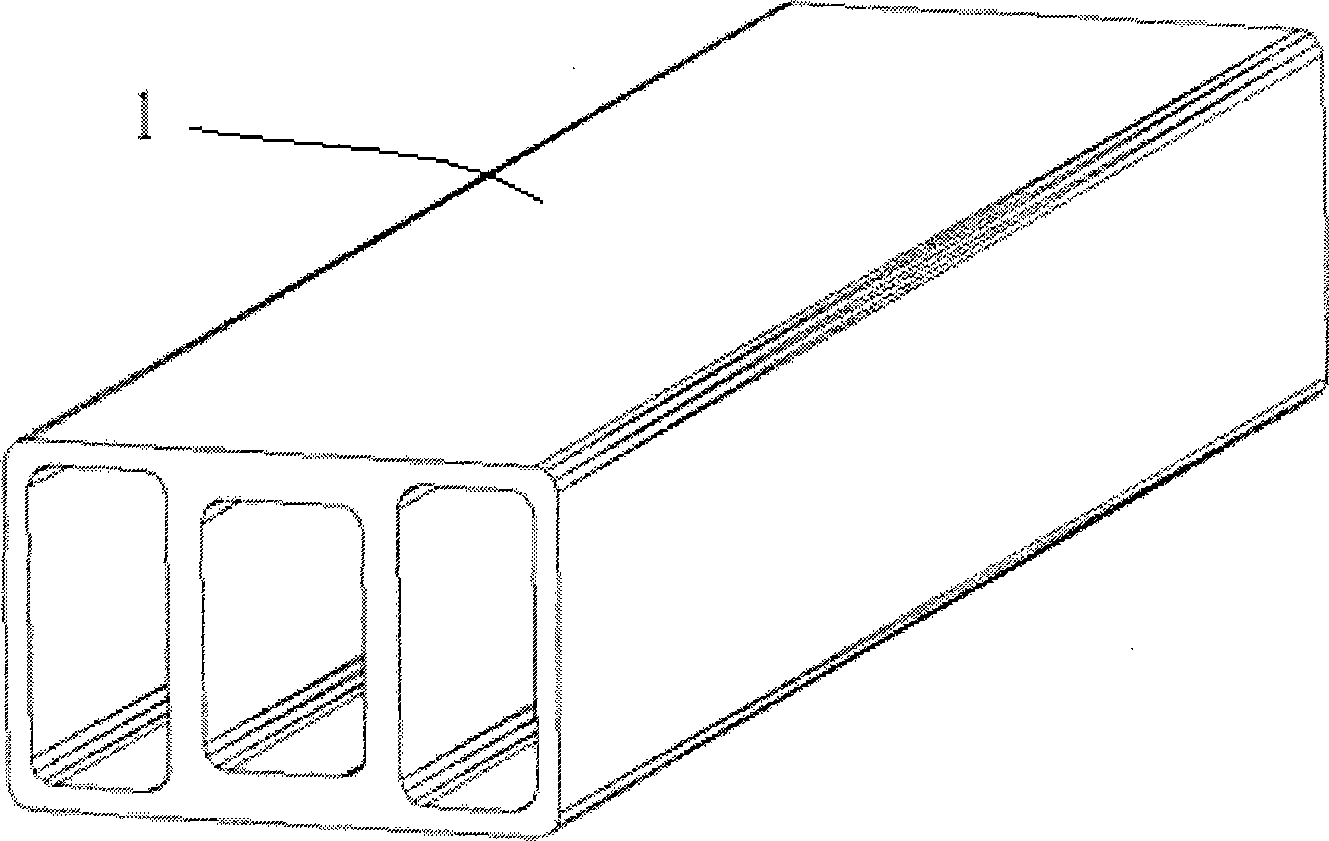

[0034] like Figure 7 As shown, the reinforced fiber synthetic sleeper 1 proposed by the present invention is made of reinforced fibers 4, fiber mats or woven cloth 5 arranged through the splitter plate 6, then impregnated with resin 7, and continuously pulled by large-tonnage traction equipment 9 to enter the section 2 The model 8 is solidified and formed in the model 8 and pulled out, and is cut according to the required length by the cutting device 10 .

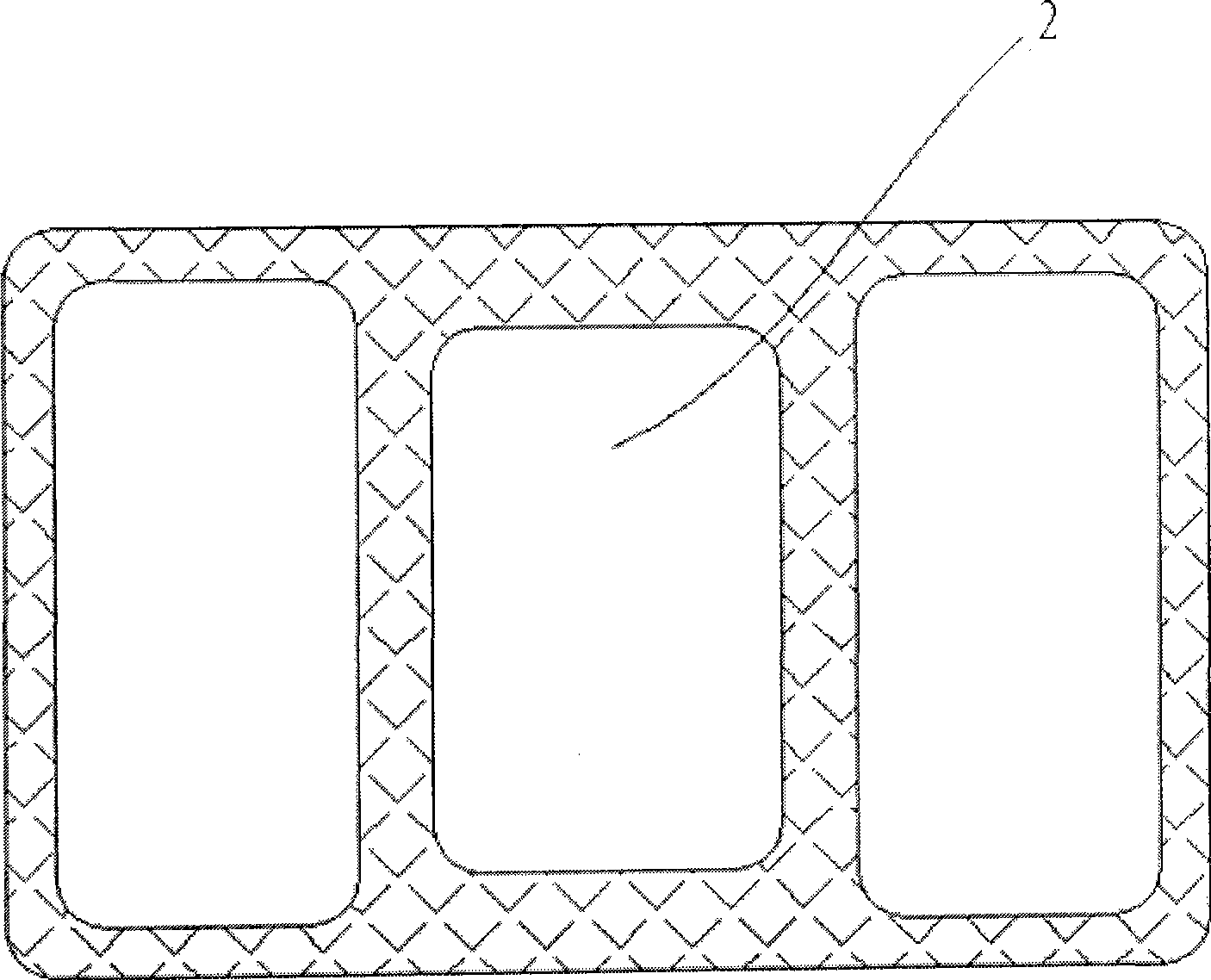

[0035] The reinforced fiber synthetic sleeper 1 proposed by the present invention is as figure 1 As shown, its section 2 is designed as figure 2 As shown, the three-box structure is adopted, and the corners are chamfered to reduce the stress concentration at the corners; the local thickness of the middle part of the upper and lower surfaces is increased, which is suitable for the installation of fasteners fixed by two anchor bolts, and the material consumption of the entire section is reduced; the middle of the section ...

Embodiment 2

[0037] like Figure 8 As shown, the reinforced fiber synthetic sleeper 11 proposed by the present invention is made of reinforced fibers 4, fiber mats or woven cloth 5 arranged through the splitter plate 12, then impregnated with resin 7, and continuously pulled by large-tonnage traction equipment 9 to enter the section 3 The model 13 is solidified and formed in the model 13 and pulled out, and is cut according to the required length by the cutting device 10 .

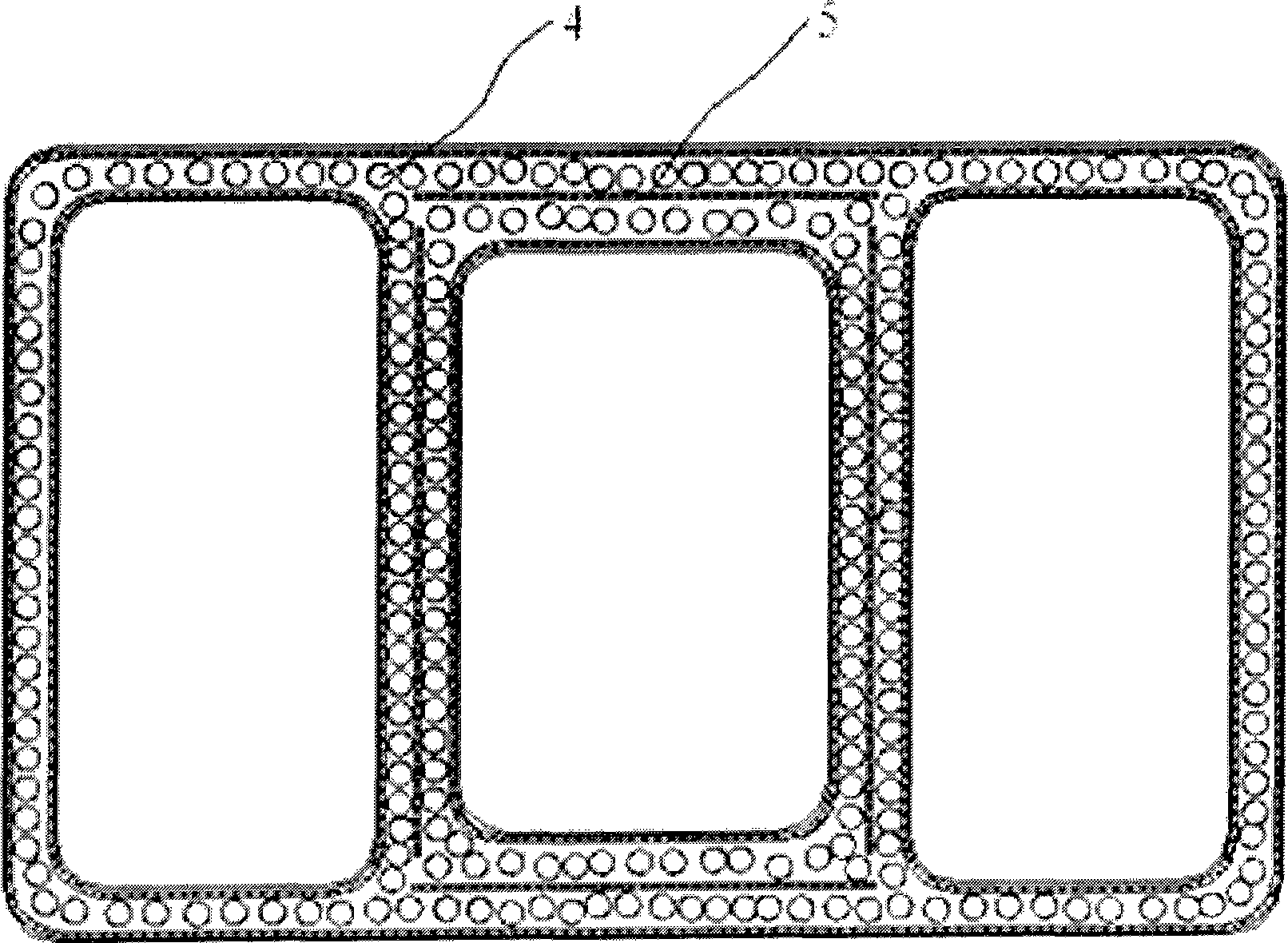

[0038] The reinforced fiber synthetic sleeper 11 proposed by the present invention is as Figure 4 As shown, its section 3 is designed as Figure 5 As shown, it adopts a double-box structure, and the chamfers around reduce the stress concentration at the corners; the thickness of the upper and lower surfaces is the same, which is suitable for the installation of fasteners fixed by 4 anchor bolts; the middle of the section is strengthened by the ribs formed during the production process to resist vertical loads capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com