Annular semiconductor device and producing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of small driving current, large driving current, low power consumption of devices, etc., so as to reduce power consumption and reduce power consumption. The effect of drive current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

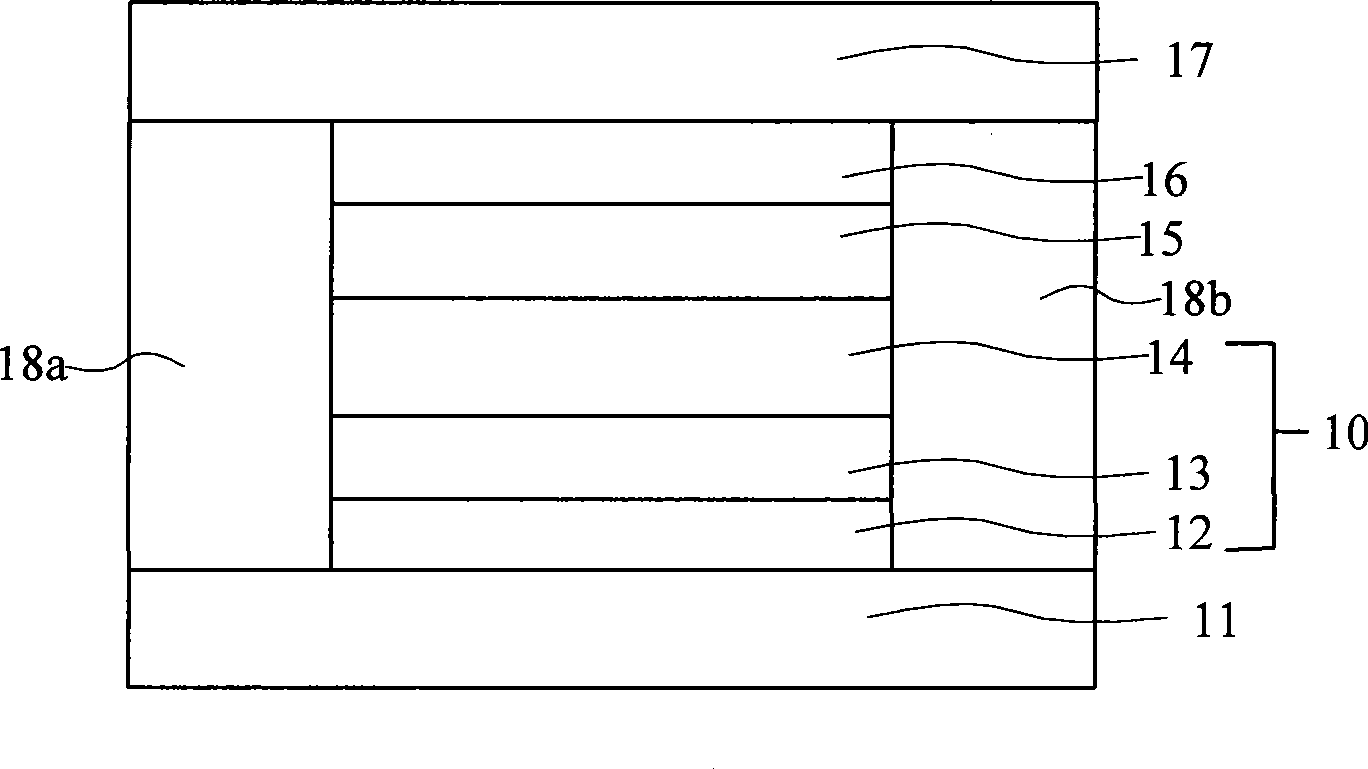

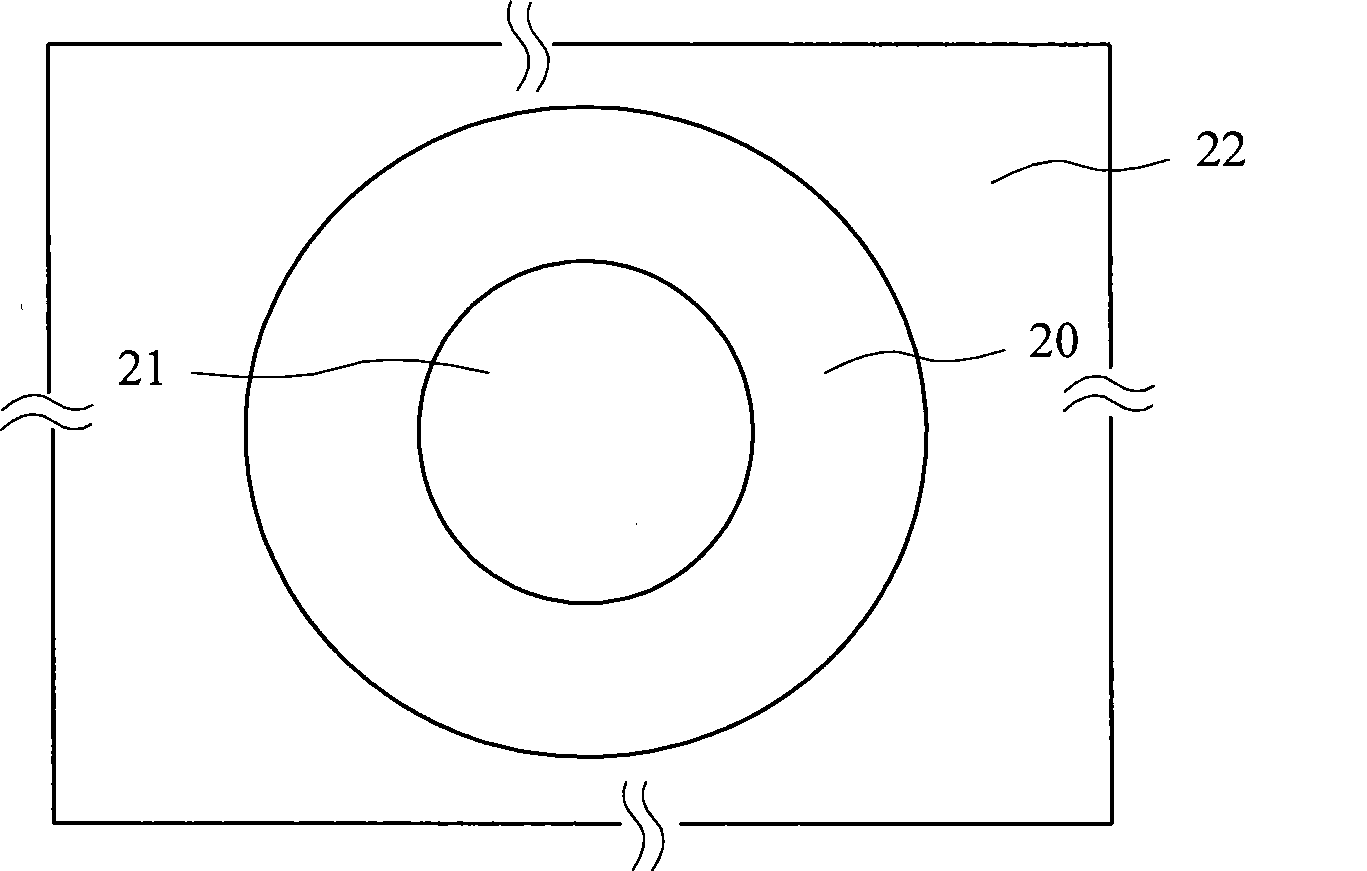

[0044] The present invention provides a ring-shaped semiconductor device and a manufacturing method thereof. The semiconductor device layer within the inner diameter of the ring-shaped semiconductor device is etched first, the first dielectric layer is filled within the inner diameter, and then the part outside the outer diameter of the ring-shaped semiconductor device is removed and the second dielectric layer is deposited. A ring-shaped semiconductor device is formed to achieve the purpose of reducing drive current and reducing power consumption.

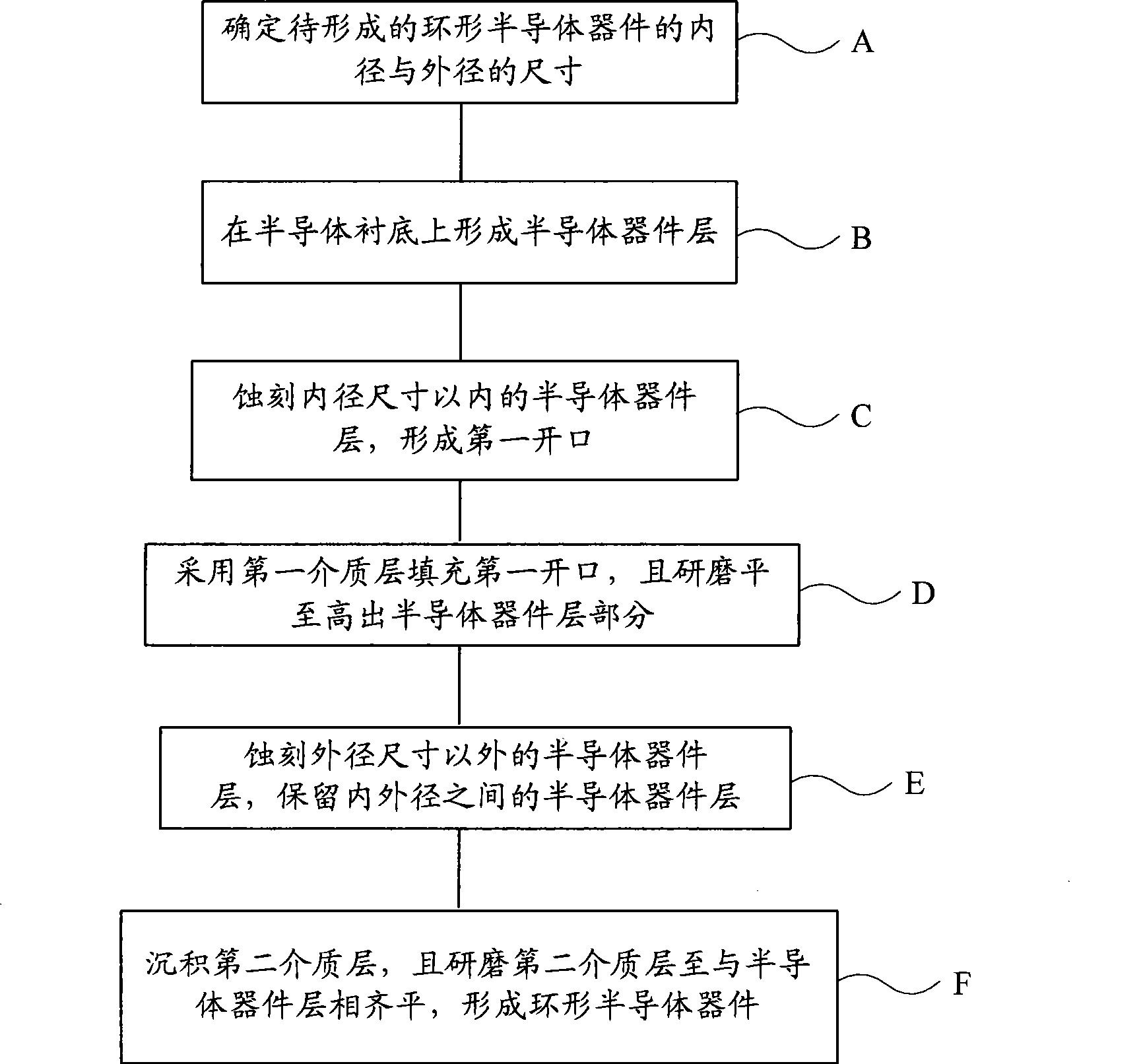

[0045] Refer to figure 2 , A schematic flow diagram of a specific embodiment of forming a ring-shaped semiconductor device of the present invention is given. It includes the following steps: performing step A to determine the inner diameter and outer diameter of the ring-shaped semiconductor device to be formed; performing step B to form a semiconductor device layer on the semiconductor substrate; performing step C to etch the semico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com