Large area melting carbonate fuel cell

A molten carbonate and fuel cell technology, applied in molten electrolyte fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of material waste, cumbersome processing methods, and incomplete utilization of materials, etc., to increase the area, Guarantee the effect of flatness and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

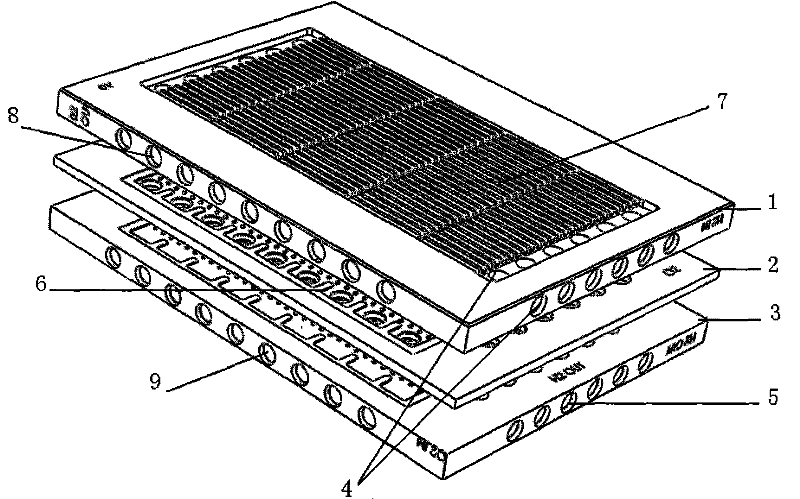

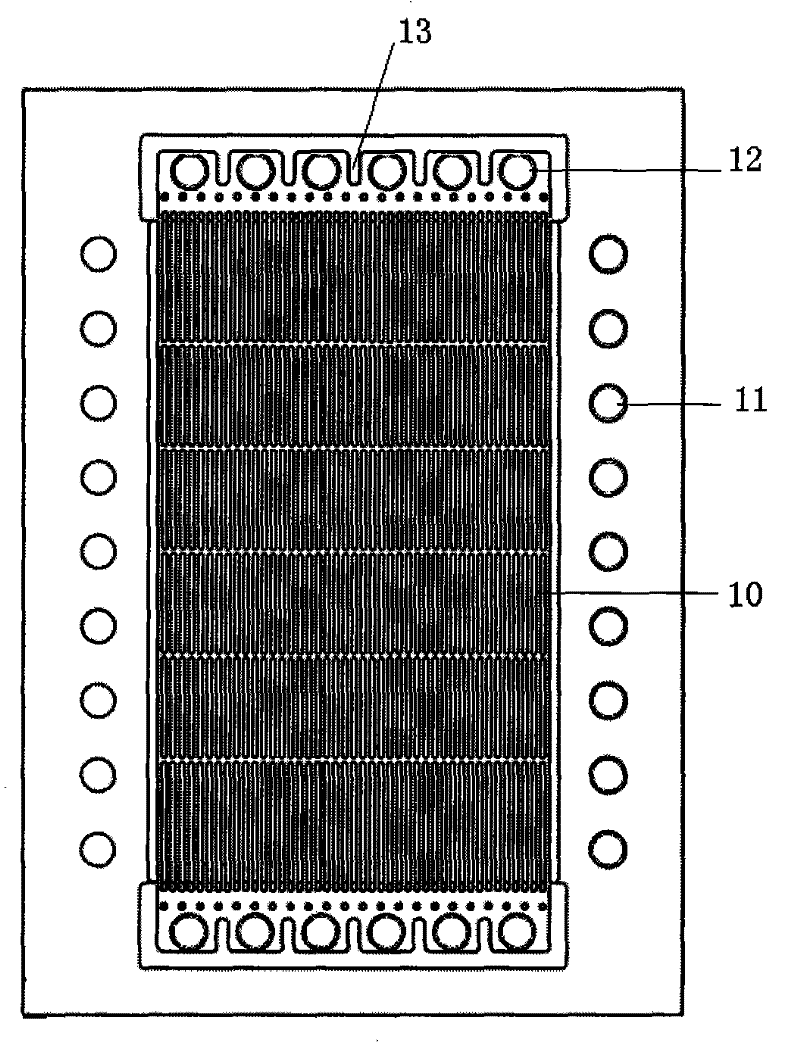

[0017] see figure 1 , 2, 3, the present invention comprises an anode heating end plate 1, a cathode heating end plate 3 and a bipolar plate 2 sealed between the anode heating end plate 1 and the cathode heating end plate 3, and the side of the anode heating end plate 1 is provided with The anode gas inlet 4 and the cathode exhaust gas outlet 8, the anode heating end plate 1 is provided with an anode preheating channel 7 connected with the anode gas inlet 4; the anode heating end plate 1 is a large-area stainless steel plate whose main function is to The anode gas is preheated, the anode gas enters the anode heating end plate from the anode gas inlet 4, and after being preheated by the anode preheating channel 7, it enters the anode gas flow channel 10 of the bipolar plate 2 along the downward direction to undergo an electrochemical reaction on the electrode surface , and finally the anode exhaust gas flows out from the anode exhaust gas outlet 5.

[0018] A cathode gas inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com