Production method of ramie spinned high count yarn and compound yarn

A production method and technology of ramie spinning, applied in textiles, papermaking, yarn and other directions, can solve the problems of strong itching, high hairiness, low yarn count, etc., achieve good evenness, expand application fields, and improve The effect of tight yarn structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

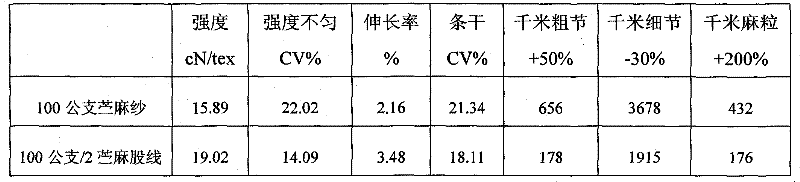

[0021] Adopt the present invention to spin the ramie strand of 100 common branch / 2, main technical process is: the twist coefficient that ramie fiber 30wt% and 30 ℃ water-soluble vinylon fiber 70wt% adopts conventional method to be spun into 13.33tex is 80 The blended single yarn, wherein the mixing method is to mix the ramie roving and the water-soluble vinylon filament on the spinning frame (during the mixing process on the spinning frame, the distance between the ramie roving and the water-soluble vinylon filament before mixing is 8mm, and the mixing method is the same as that in the patent 200810204366.5), and then remove the vinylon in water at 30°C for 4 hours after the single yarn, wash it with water after completely removing the vinylon, and then dry it at 50°C for 6 hours to obtain ramie single yarn with a fineness of 100 metric counts, and then remove the single yarn Carry out plying, obtain the strand that fineness is 100 common branch / 2, because this strand is used ...

Embodiment 2

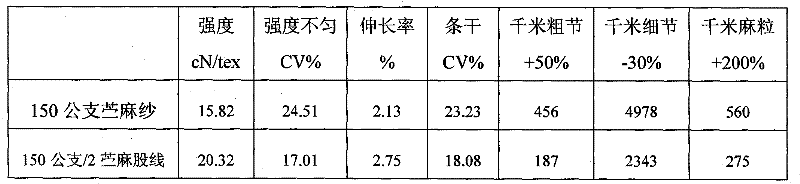

[0024] Adopt the present invention to spin 150 / 2 common ramie strands, its technological process is: adopt conventional method to spin ramie fiber 90wt% and water-soluble vinylon fiber 10wt% into the blended single yarn that the twist coefficient of 11.1tex is 120, Wherein the mixing method is to realize the mixing of ramie roving and water-soluble vinylon filament on the spinning frame (in the mixing process on the spinning frame, the distance between the ramie roving and the water-soluble vinylon filament before mixing is 0mm, and the mixing method is the same as the patent 200810204366.5), and then Put the yarn in water at 100°C to remove vinylon for 2 hours. After the vinylon is completely removed, wash it with water and dry it at 100°C for 1 hour to obtain ramie single yarn with a fineness of 150 mm. In this example, the strands are used as It is used for knitting or weft yarn, so the twist coefficient 120 is the same as that of the single yarn, and the ramie strands with ...

Embodiment 3

[0028] Using the present invention to spin ramie strands with 300 public counts / 2 public counts, the technological process is as follows: 60 wt% of ramie fibers and 40 wt% of water-soluble vinylon fibers are spun into 5.56tex blended single yarns with a twist coefficient of 140 by conventional methods , wherein the mixing method is loose fiber mixing, and then the vinylon is removed at 100°C for 0.5 hours. After the vinylon is completely removed, it is washed with water and dried at 120°C for 0.5 hours to obtain a ramie single yarn with a fineness of 300 public counts. The single yarn can be plyed to obtain ramie strands with a fineness of 150 metric and a twist coefficient of 170.

[0029] In this embodiment, the vinylon that is soluble in water at 95°C is selected, so sodium hydroxide (2.2 g per 5 L of water) and JFC (2.2 g per 5 L of water) are added during the vinylon removal process to speed up the removal of vinylon. The ramie strand quality that present embodiment makes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com