Solvent composition for manufacturing stacked capacitor

A technology of solvent composition and laminated capacitors, which is applied to the parts of fixed capacitors, fixed capacitor dielectrics, inorganic insulators, etc., can solve the problem of not being able to stably inhibit sheet erosion, effectively preventing sheet erosion, mixing ratio or Purity changes and other issues, to achieve the effect of inhibiting and preventing sheet erosion, low toxicity, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

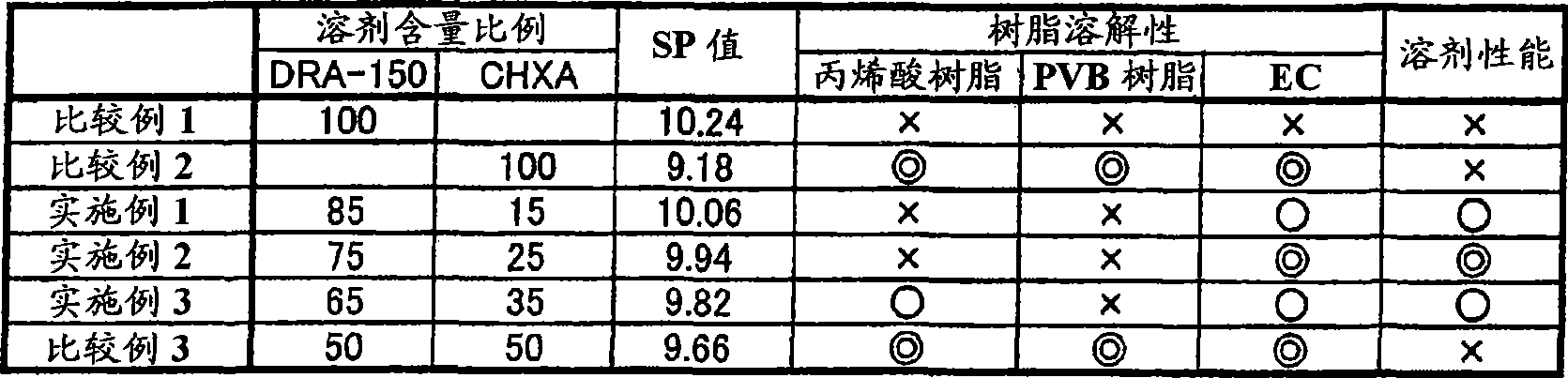

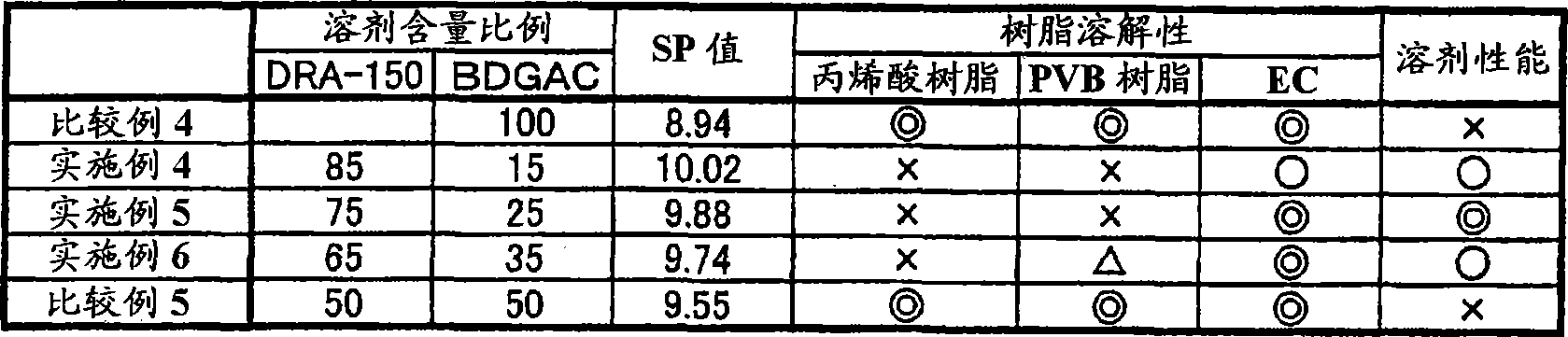

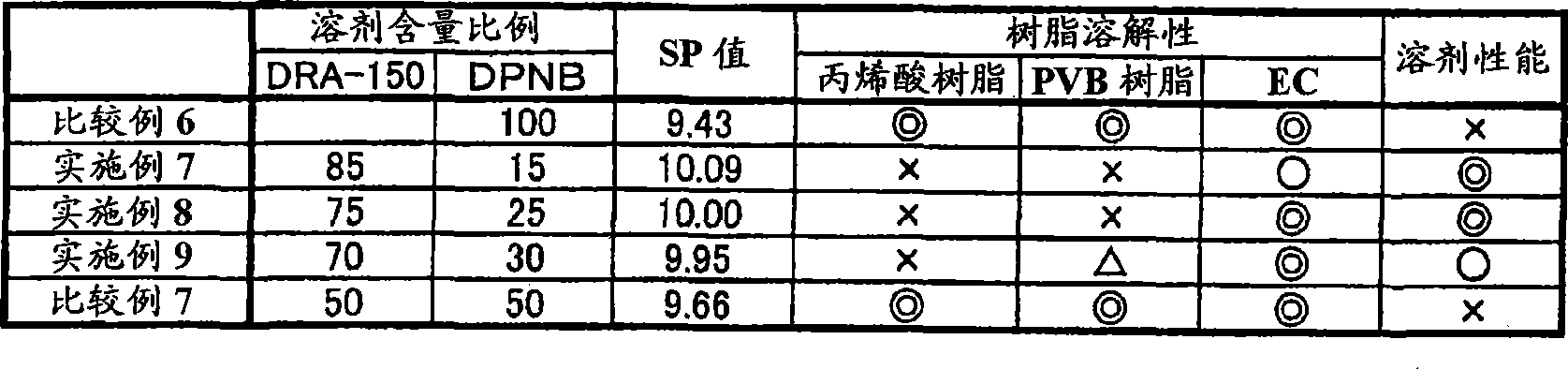

[0046] (Examples 1-15, Comparative Examples 1-10)

[0047] Glyceryl triacetate (DRA-150, manufactured by Daicel Chemical Co., Ltd.) and solvent A were mixed according to the ratios described in Tables 1 to 5 below to prepare a solvent composition. The solvent composition was divided into three parts, and an acrylic resin (trade name "Elvacite (Elvacite) 2045" manufactured by DuPont) was added to the first part of the solvent composition, and a polyacrylate resin was added to the second part of the solvent composition. Vinyl butyral resin (trade name "S-REC (エスレック) BL" manufactured by Sekisui Chemical Co., Ltd.), ethyl cellulose (trade name "ETHOCEL STD (エトセルSTD)" was added to the third solvent composition Dow Chemical Co., Ltd.), each resin concentration was 5% by weight, heated and dissolved at a liquid temperature of 65° C. for 3 hours, and then left to cool.

[0048] (evaluate)

[0049] The solubility of each resin to each solvent composition was visually observed for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com