Photosensitive, aqueous alkaline solution-soluble polyimide resin and photosensitive resin composition containing the same

A technology of polyimide resin and alkali aqueous solution, which is applied in the field of photosensitive resin composition, and can solve problems such as inability to bend excessively, insufficient flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

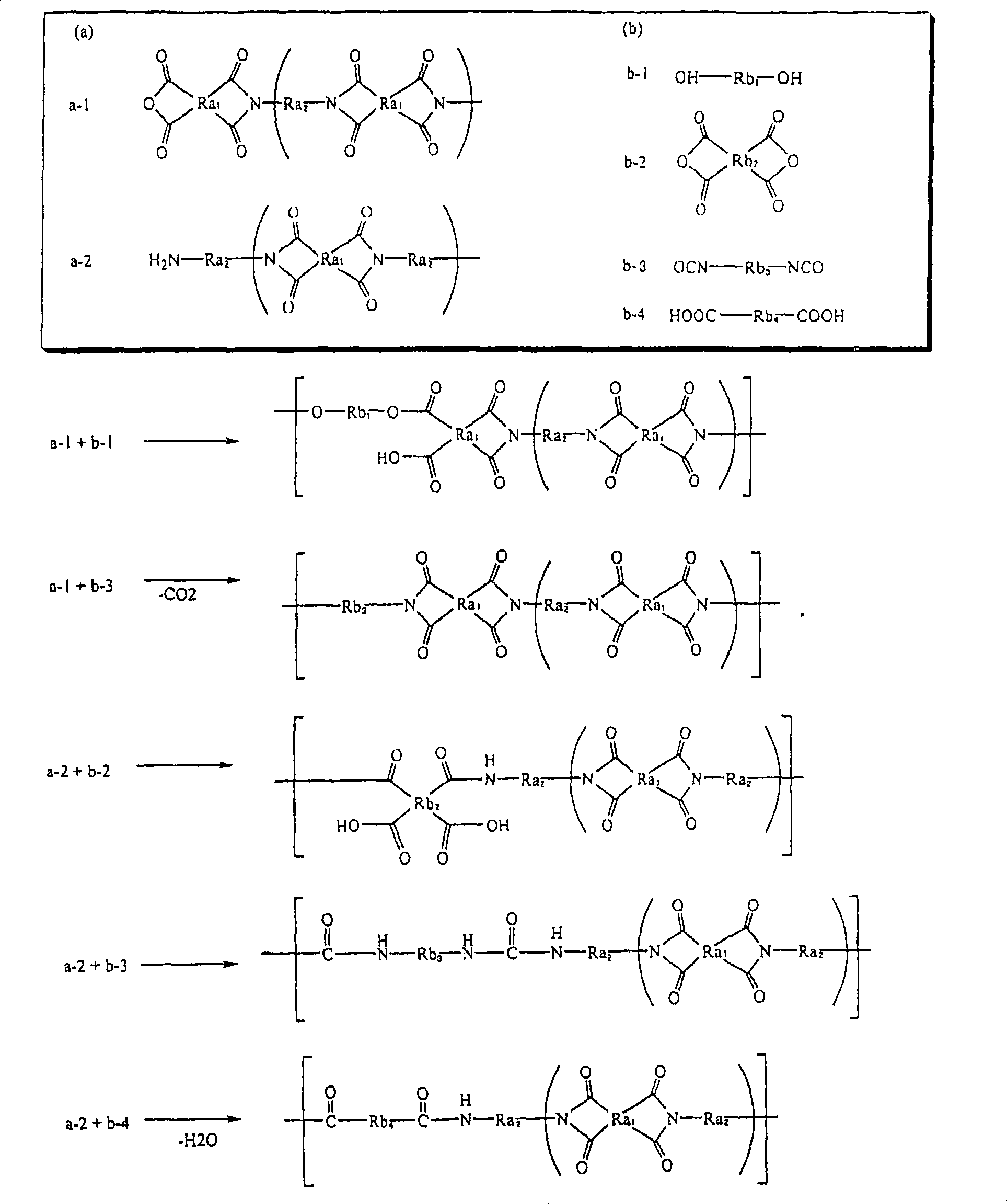

Method used

Image

Examples

Embodiment

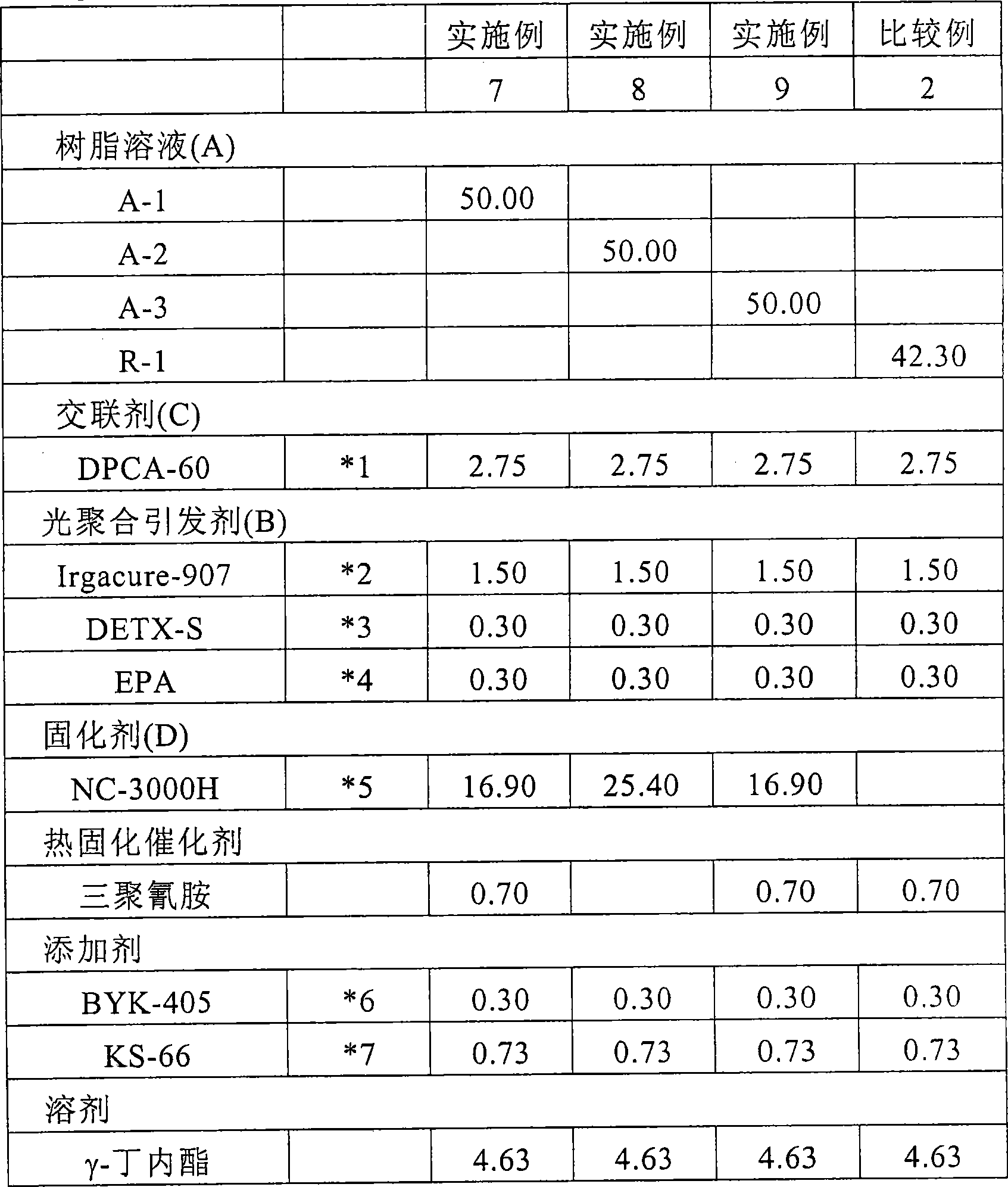

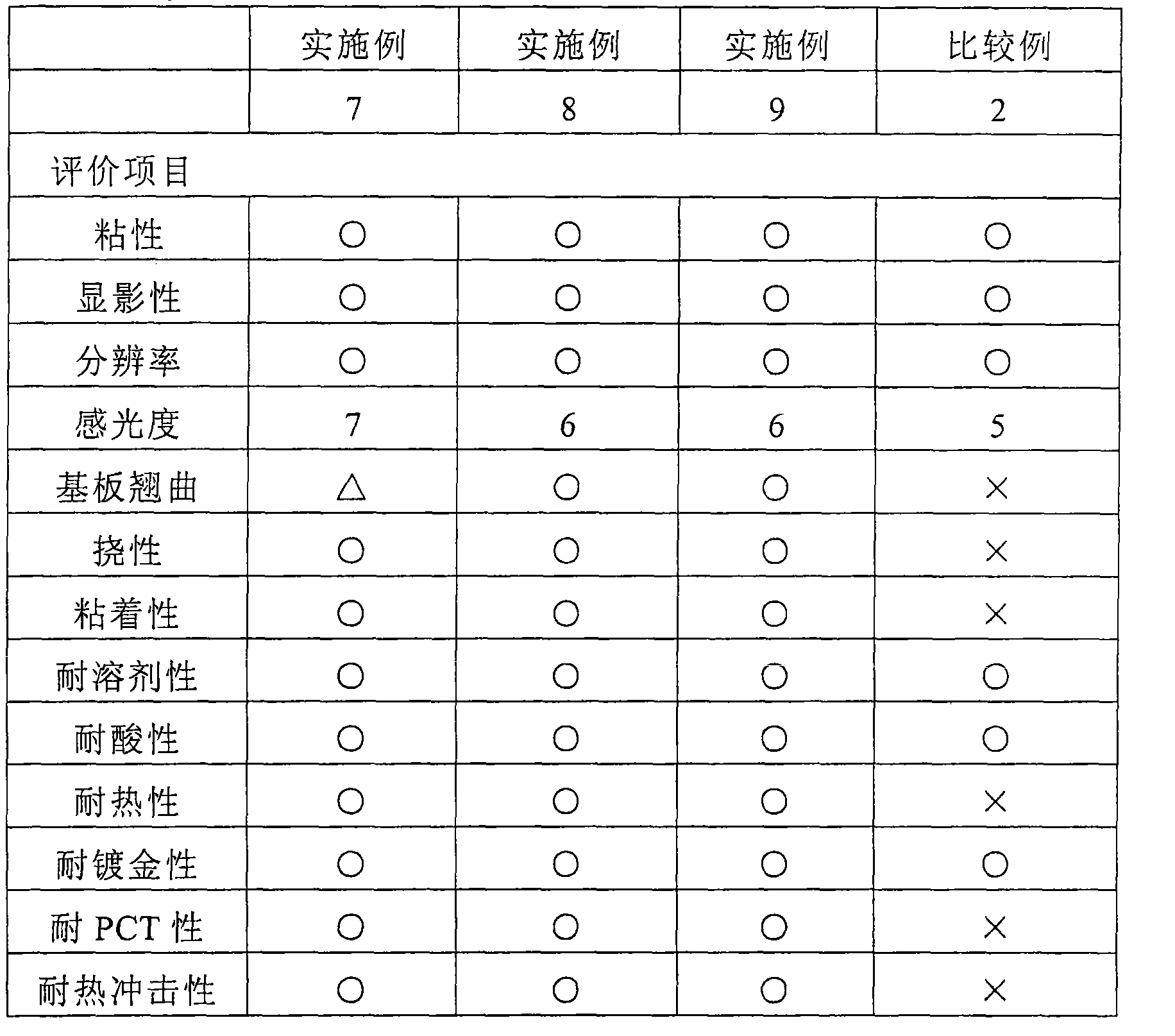

[0120] Hereinafter, the present invention will be described in more detail through examples, but the present invention is not limited to the following examples.

Synthetic example 1

[0122] Synthetic polyimide resin (a-1)

[0123] After nitrogen purging was carried out in the 3L flask with stirring device, reflux pipe, water trap (water trap) and thermometer, add gamma-butyrolactone 1052.3g, PMDA (pyromellitic anhydride, Degussa company manufacture) as solvent , molecular weight 218.1) 87.3 g, ODPA (3,3'4,4'-diphenyl ether tetracarboxylic dianhydride, manufactured by MANAC, molecular weight 310.2) 279.2 g, 3,4'-diaminodiphenyl ether (Mitsui Chemical Co., Ltd., molecular weight 200.2) 200.2g, γ-valerolactone 13.0g, pyridine 20.6g, and toluene 20g as a catalyst, reacted at 180°C for 8 hours, while removing the water generated by the reaction, the dehydrating agent toluene, and the catalyst, While stirring, a resin solution containing 35% of polyimide resin was obtained (this solution is referred to as (a-1)). The weight average molecular weight is 17700.

Synthetic example 2

[0125] Synthetic polyimide resin (a-2)

[0126] After purging nitrogen in the 5L flask with stirring device, reflux pipe, water trap and thermometer, add gamma-butyrolactone 1741.4g, DSDA (3,3'4,4'-diphenylsulfone Tetracarboxylic dianhydride, manufactured by Nippon Chemical Co., Ltd., molecular weight 358.28) 358.3 g, BY16-853U (polysiloxane diamine, manufactured by Toray Dow Corning Co., Ltd., molecular weight 926) 370.4 g, ADPE (3,3 '-Diamino-4,4'-dihydroxydiphenyl ether, manufactured by Nippon Kayaku Co., Ltd., molecular weight 232.24) 209.0 g, γ-valerolactone 10.0 g as a catalyst, pyridine 15.8 g, toluene 20 g, at 180 The mixture was reacted at °C for 8 hours and stirred while removing generated water, dehydrating agent toluene, and catalyst to obtain a resin solution containing 35% of polyimide resin (this solution is referred to as (a-2)). The weight average molecular weight is 23200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Solid content acid value | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com