Foaming chemical grout

A chemical slurry and slurry technology, applied in application, telephone communication, electrical components, etc., can solve the problems of complex repair and reinforcement methods of structures, unable to show the original function of fillers, and poor recovery effect of damaged appearance. Excellent adhesion and operability, firm adhesion, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

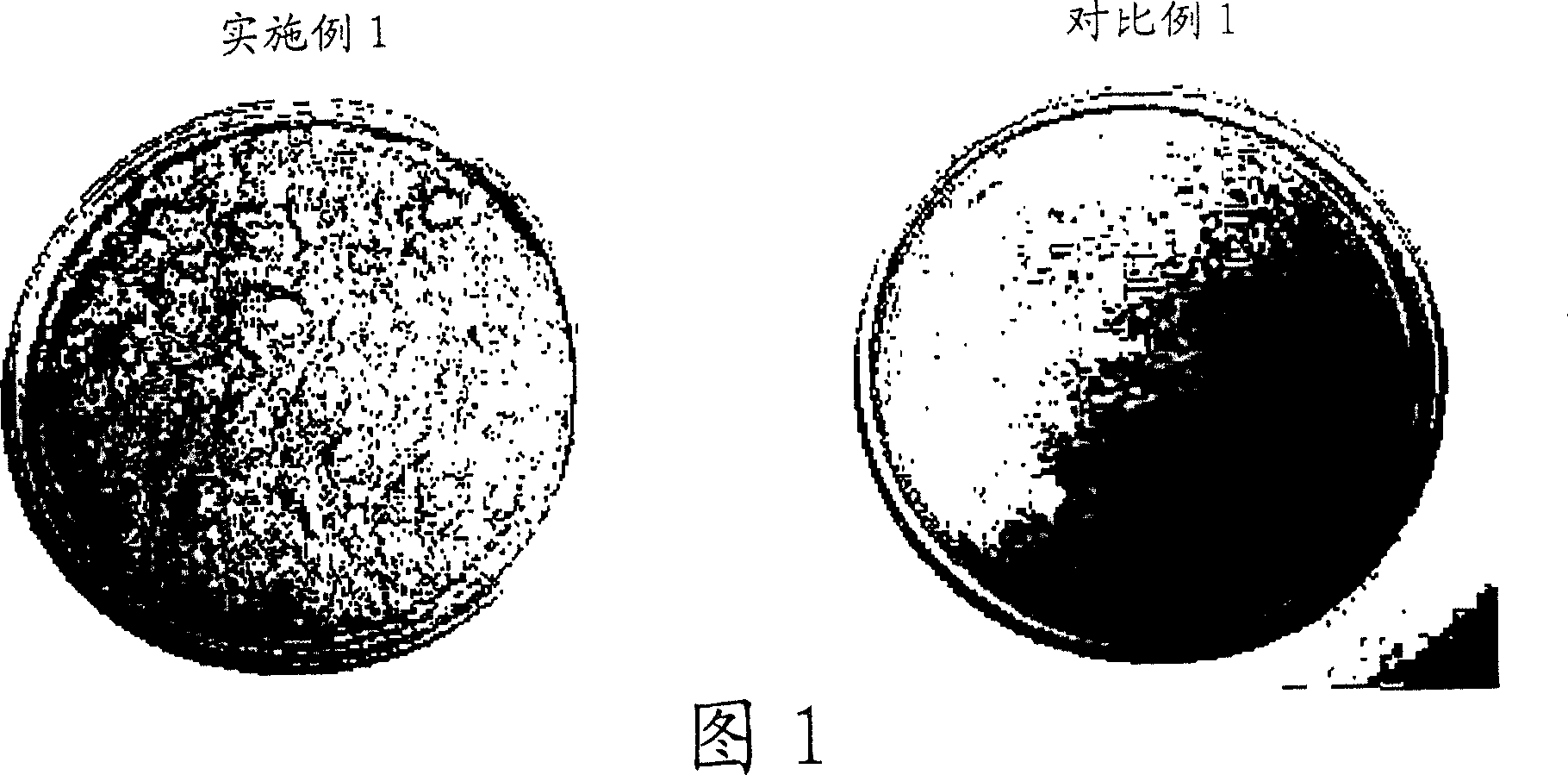

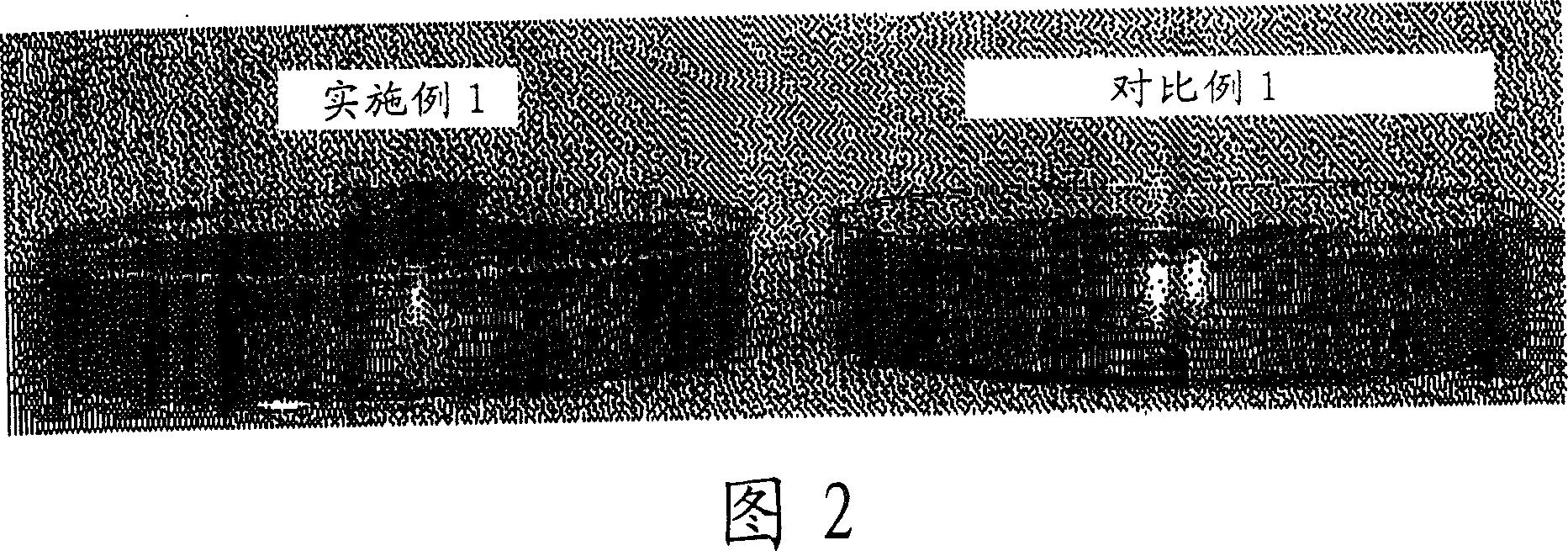

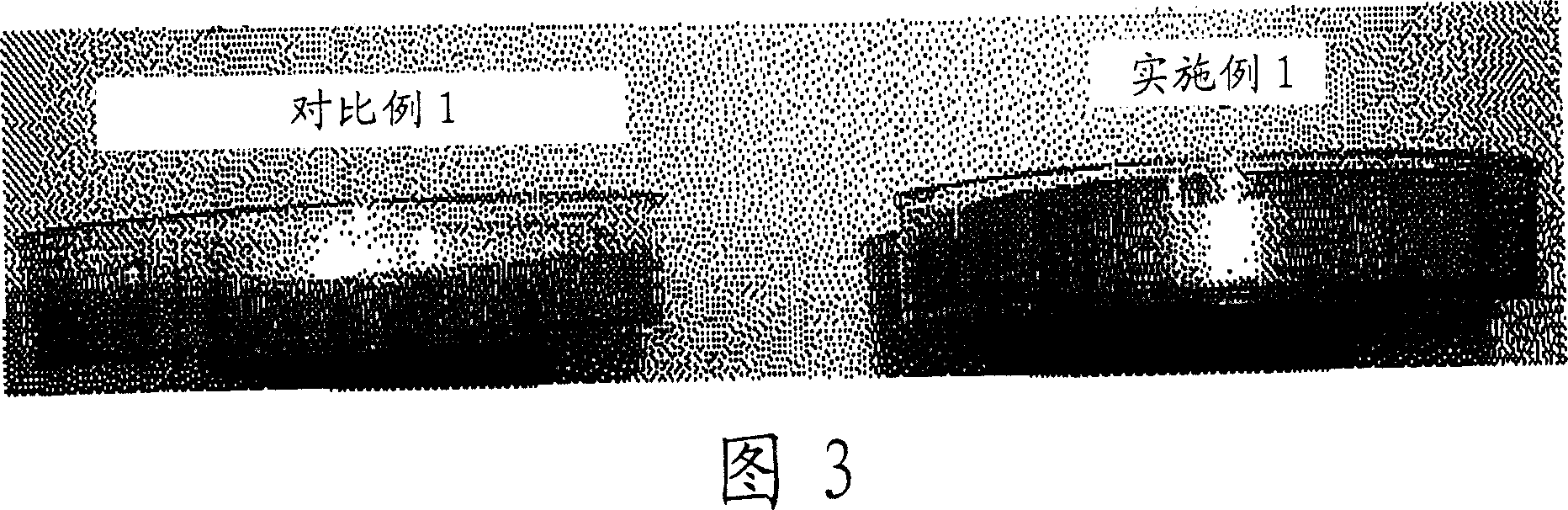

Embodiment 1

[0093] Evenly mix 1 kg of liquid epoxy resin, 1 kg of glass powder having an average diameter of 200 mesh and a specific gravity of 2.54, 300 g of glass beads with an average diameter of 0.1 mm as filler, 50 g of NaCl as an alkali metal compound or alkaline earth metal compound, and 300 g Solvent, from which the main ingredient is prepared.

[0094] Next, 500 g of aluminum powder, 300 g of glass beads having an average diameter of 0.1 mm as a filler, and 400 g of an epoxy hardening agent were uniformly mixed, thereby preparing a hardener.

[0095] The foaming chemical paste is prepared by mixing the above-prepared main ingredients and hardener.

Embodiment 2

[0097] According to the same method as in Example 1, the main component and the hardener were mixed to prepare a foamed chemical slurry, except that 100 g of ground glass fibers having an average fiber diameter of 13.5 μm and an average fiber length of 300 μm were added to Example 1. 1 in the principal component.

Embodiment 3

[0099] According to the same method as Example 1, mix the main component and hardener to prepare foaming chemical slurry, the difference is to use calcium carbonate (CaCO 3 ) to replace the glass beads of Example 1 as filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com