Method for producing plastic lens

A technology of plastic lens and manufacturing method, which is applied in the direction of lens and patterned surface photoplate making process, instruments, etc., and can solve the problems of complex lens forming process and expensive processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

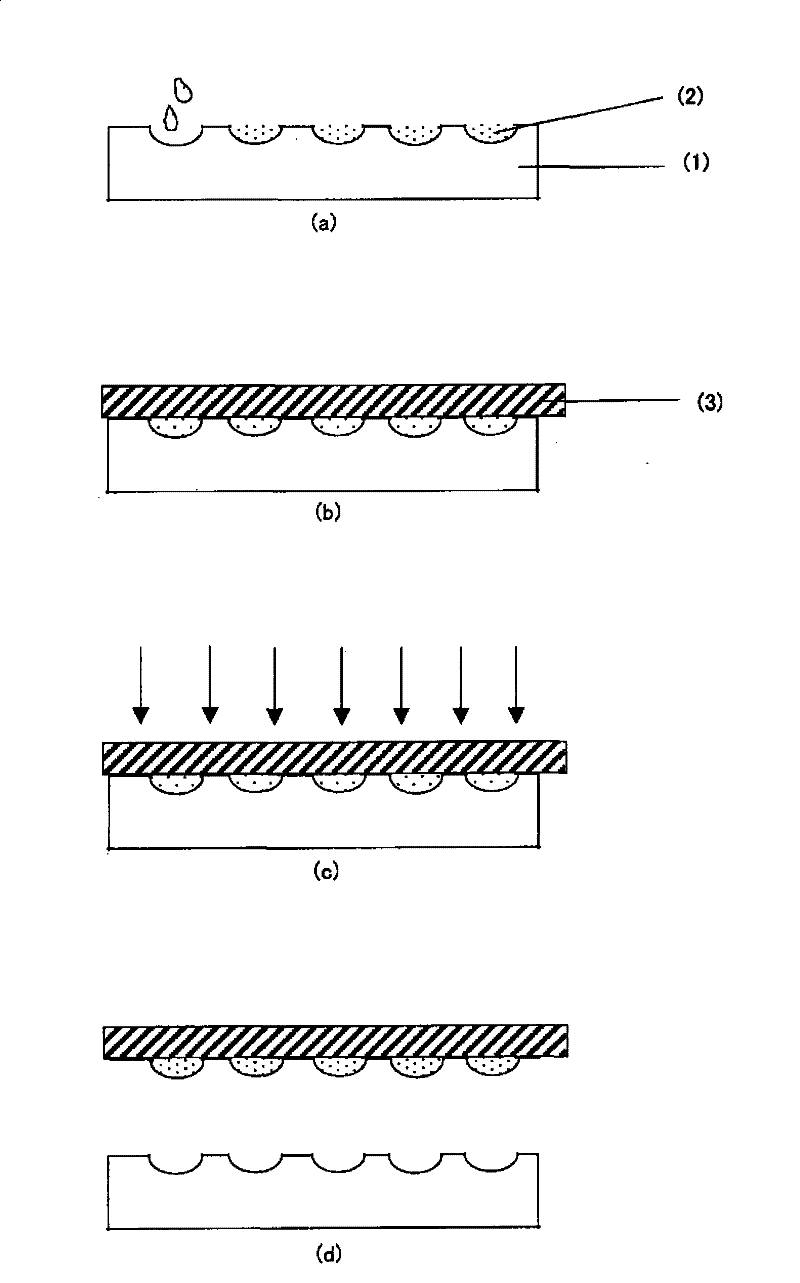

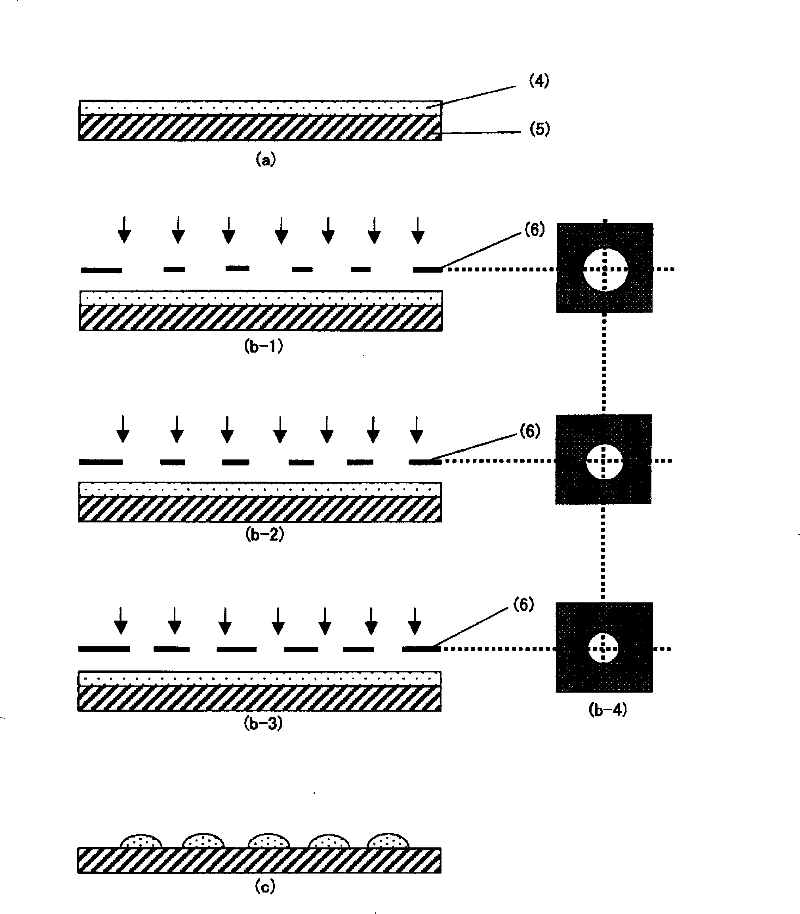

[0127] [Embodiment 1] Manufacturing method of microlens 1 utilizing mold

[0128] Carry out the following steps in sequence to manufacture the microlens.

[0129] Step 1) Using a glass pipette, drop 5 drops of the above photosensitive resin composition 1 into a plastic lens mold made of nickel with a maximum depth of 30 μm, a diameter of 100 μm, and several hundred openings, to combine the photosensitive resin Object 1 fills the mold. An alkali-free glass substrate (10 cm square, 0.7 mm thick) manufactured by Corning was used as a substrate, and the opening of the mold was pressed onto the substrate.

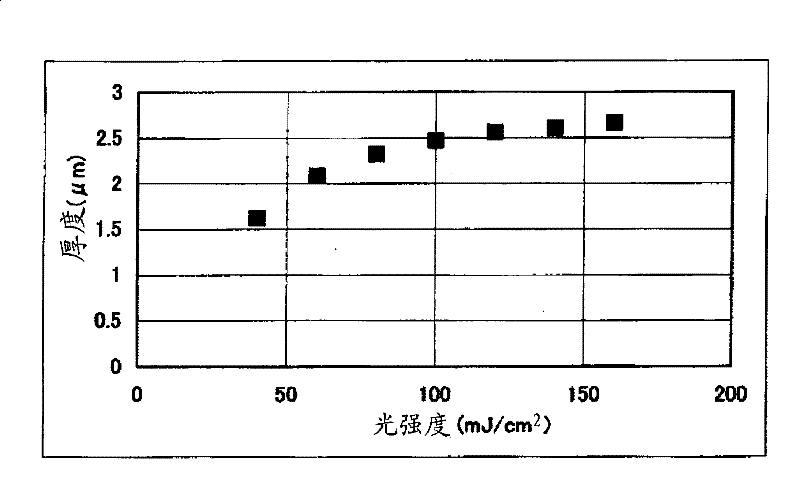

[0130] Step 2) In the state where the photosensitive resin composition is sandwiched between the substrate and the mold, using a proximity exposure device manufactured by CANON, a mirror image projection aligner is used to irradiate the entire surface with ultraviolet rays without a mask from the glass substrate side. The irradiation dose at i-ray wavelength (365nm) is 400mJ / c...

Embodiment 2

[0133] [Embodiment 2] Manufacturing method of microlens 2 utilizing mold

[0134] It carried out similarly to Example 1 except that the 1st step was the following procedure.

[0135] Step 1) Use Corning's alkali-free glass substrate (10cm square, 0.7mm thickness) as the substrate, use MEMO as the silane compound, dilute the MEMO to 5% by weight with NMP solvent, and use it at 1000rpm for 20 seconds Spin coater for coating. The coated glass substrate was heated with the silane compound-attached surface facing upward at 120° C. for 5 minutes on a hot plate, and then cooled. The thickness of the silane compound layer of the obtained silane compound-attached substrate was 0.01 μm or less. Using a glass pipette, 5 drops of the above-mentioned photosensitive resin composition 1 were dropped into a plastic lens mold made of nickel having an opening, so that the mold was filled with the photosensitive resin composition 1 . Next, the opening of the mold is pressed against the silane...

Embodiment 3

[0136] [Embodiment 3] Manufacturing method of microlens 3 utilizing mold

[0137] Except having used the photosensitive resin composition 2 instead of the photosensitive resin composition 1, it carried out similarly to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com