Lactobacillus beverage containing gamma-aminobutyric acid and method for producing the same

A lactic acid bacteria beverage and aminobutyric acid technology, which is applied in the field of dairy product manufacturing, can solve the problem that γ-aminobutyric acid cannot pass through the brain closing door, etc., and achieve the effects of enriching nutrition and relieving physical fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

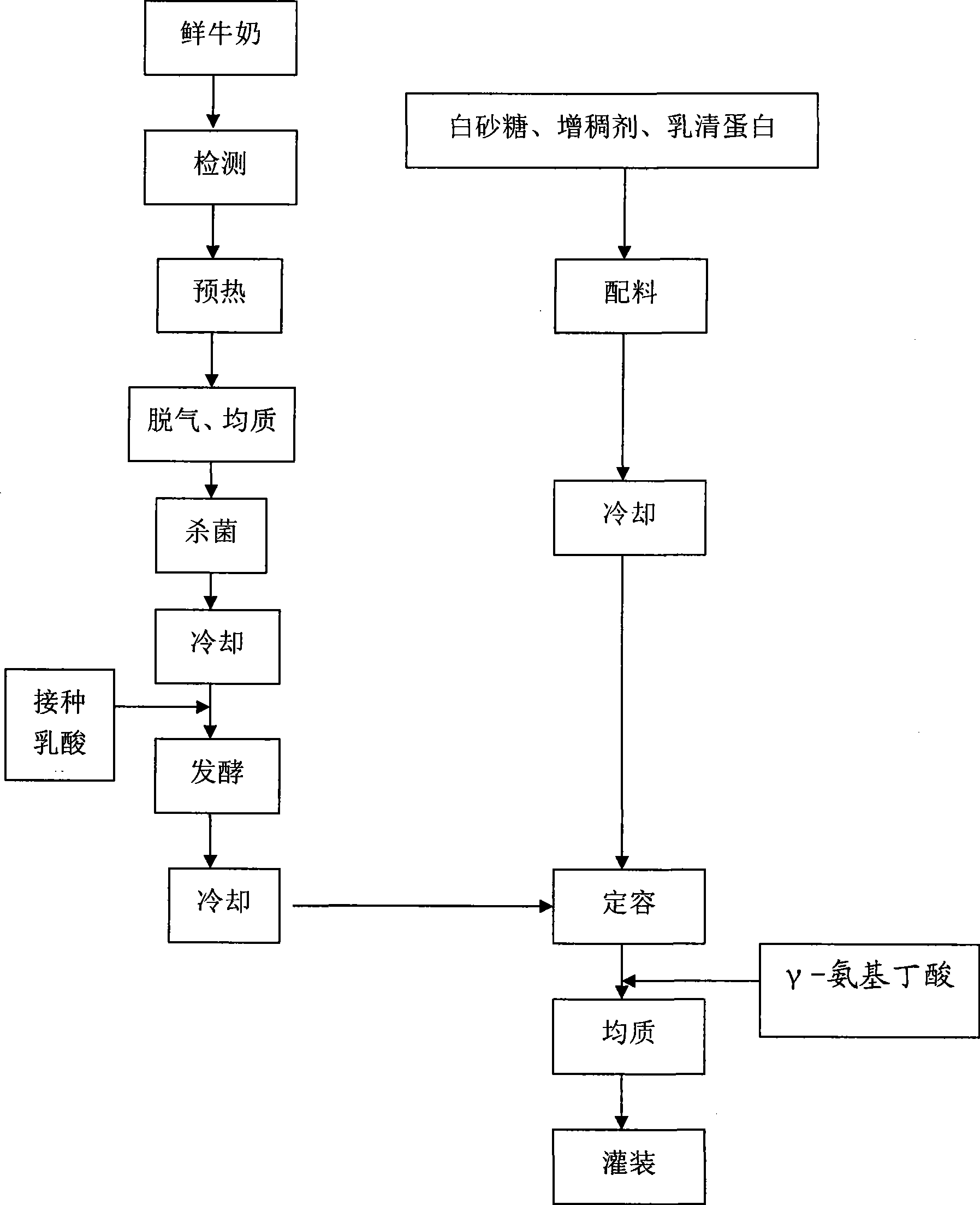

Image

Examples

Embodiment 1

[0037] The product of this embodiment includes lactic acid bacteria beverage and γ-aminobutyric acid, wherein, by weight percentage: γ-aminobutyric acid accounts for 0.1%, and the rest is lactic acid bacteria beverage. The product formula is:

[0038]According to weight percentage, γ-aminobutyric acid accounts for 0.1%, white granulated sugar accounts for 6%, thickener accounts for 0.2%, whey protein accounts for 0.01%, lactic acid bacteria accounts for 0.1%, and the rest is milk. Its production includes the following steps: constant volume of raw milk ingredients, preheating, homogenization, sterilization, cooling, inoculation, fermentation, after cooling, it enters the beverage storage tank and mixes it with a thickening agent, constant volume, flavoring, and γ - After GABA is added to the lactic acid bacteria beverage, homogenize, then enter the storage tank and stir for 15-25 seconds.

[0039] Further instructions are as follows:

[0040] 1. Milk inspection: no antibioti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com