High purification treatment system for dyeing wastewater

A technology for printing and dyeing wastewater and treatment system, which is applied in textile industry wastewater treatment, oxidized water/sewage treatment, biological water/sewage treatment, etc. The effect of increasing the rate, reducing the harm, and improving the biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

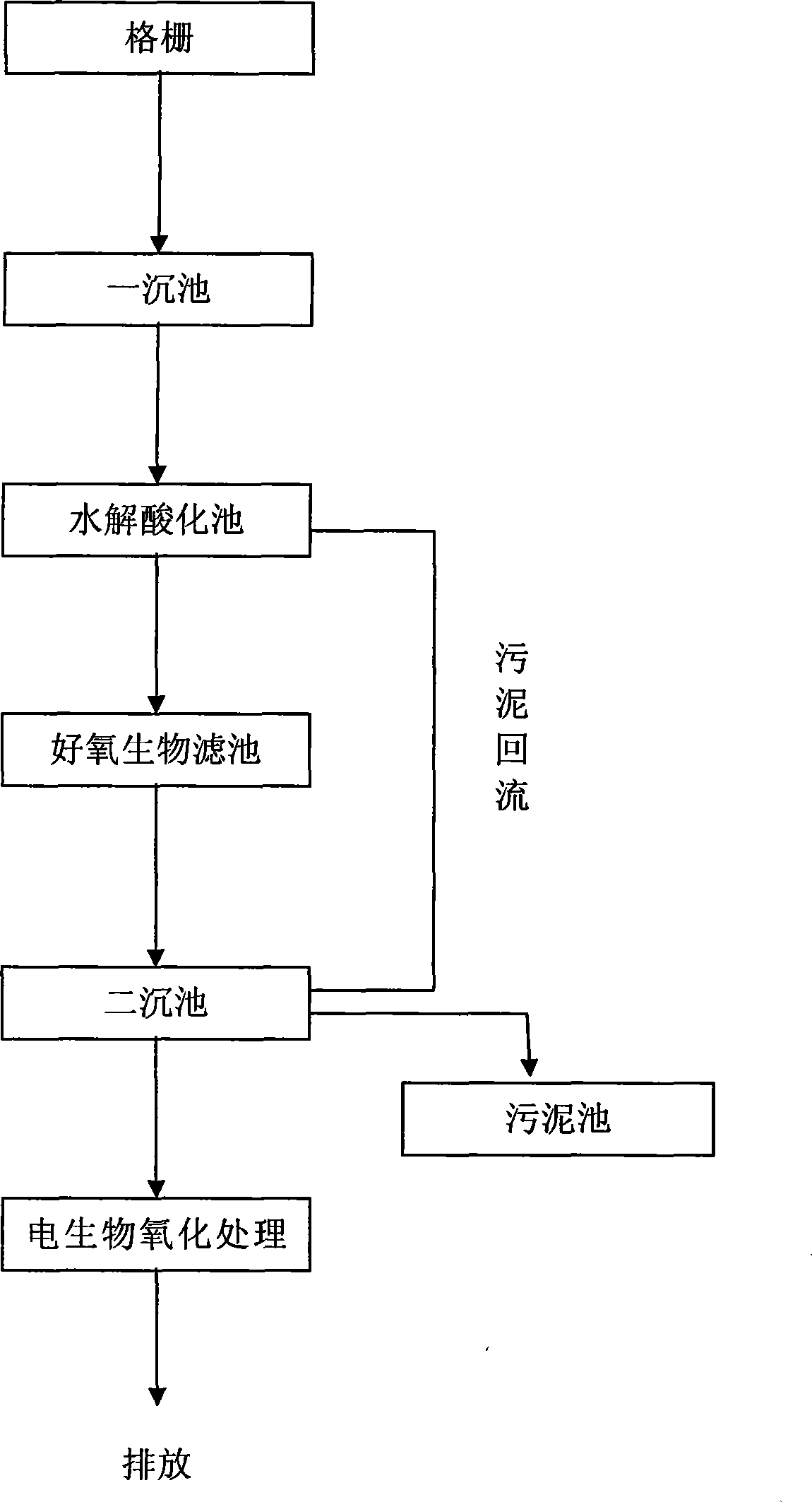

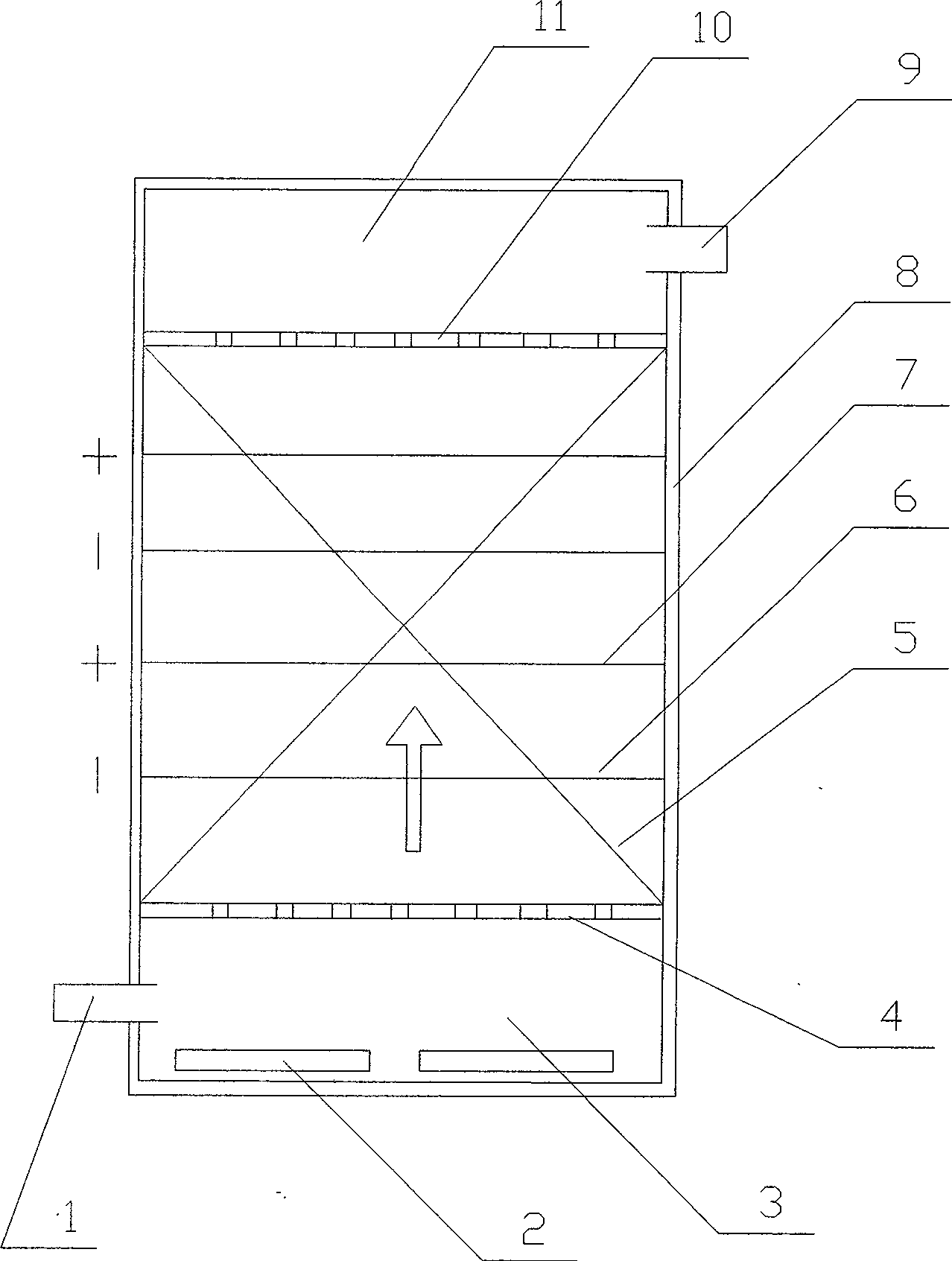

[0008] see figure 1 , the high-purity printing and dyeing wastewater treatment system provided by the present invention is mainly composed of a pre-aeration adjustment tank, a settling tank, a hydrolytic acidification tank, an aerobic biological filter, a second settling tank and photocatalytic oxidation purification equipment. tank, primary sedimentation tank, hydrolytic acidification tank, aerobic biofilter, secondary sedimentation tank, and electrobiological oxidation treatment tank are connected to each other in turn, and the photocatalytic oxidation purification equipment includes a shell, and a space for forming a water flow channel is arranged in the shell , the space forming the water flow channel is provided with biological fillers, and several pairs of electrodes are also provided, and the extension direction of the electrodes is perpendicular to the extension direction of the water flow channel.

[0009] A grille may be arranged in front of the pre-aeration regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com