Wide temperature zone high damping cushion rubber

A shock-absorbing rubber and high-damping technology, which is applied in the production field of shock-absorbing rubber, can solve problems such as reducing the damping effect, and achieve the effect of high electrical insulation and high damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

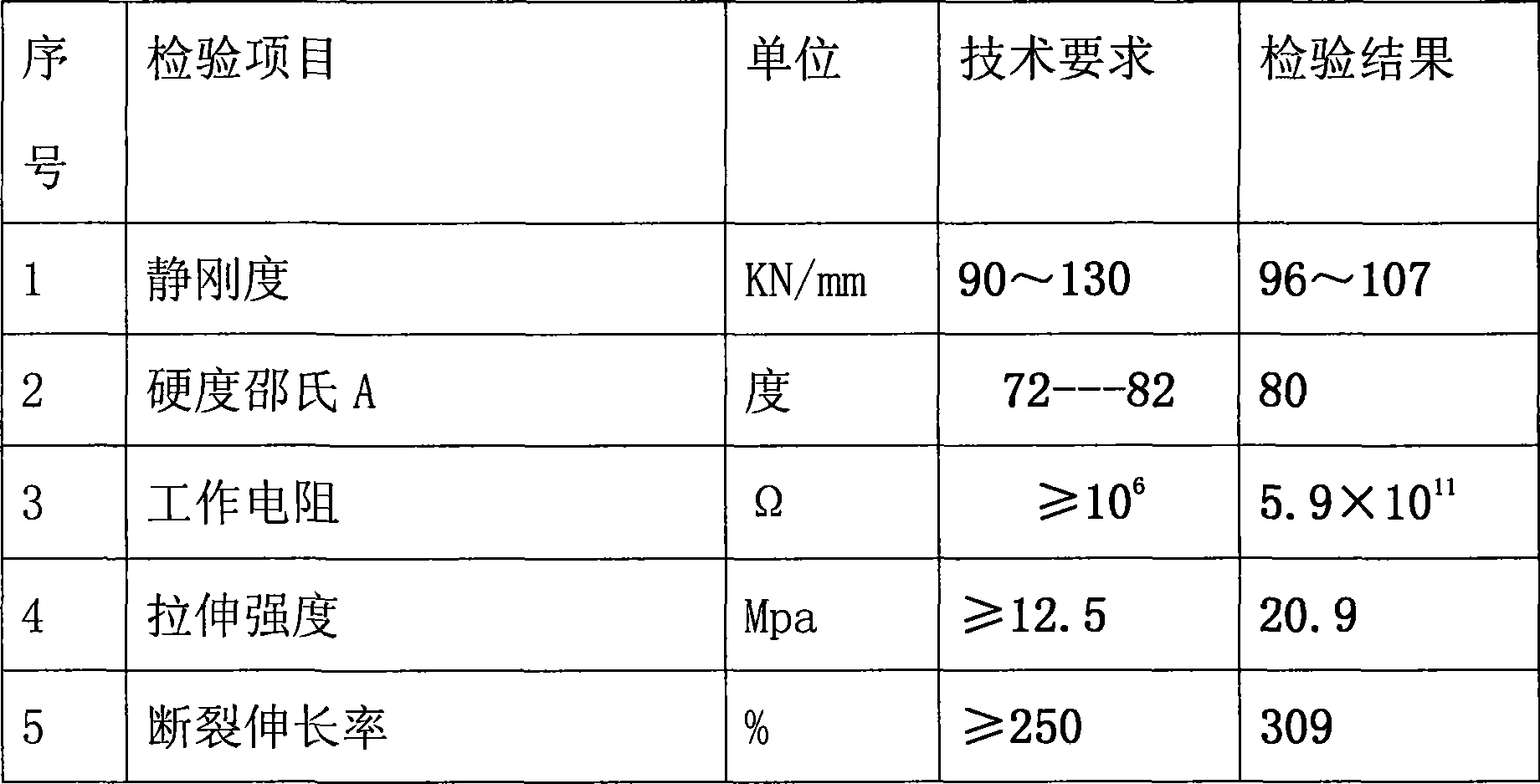

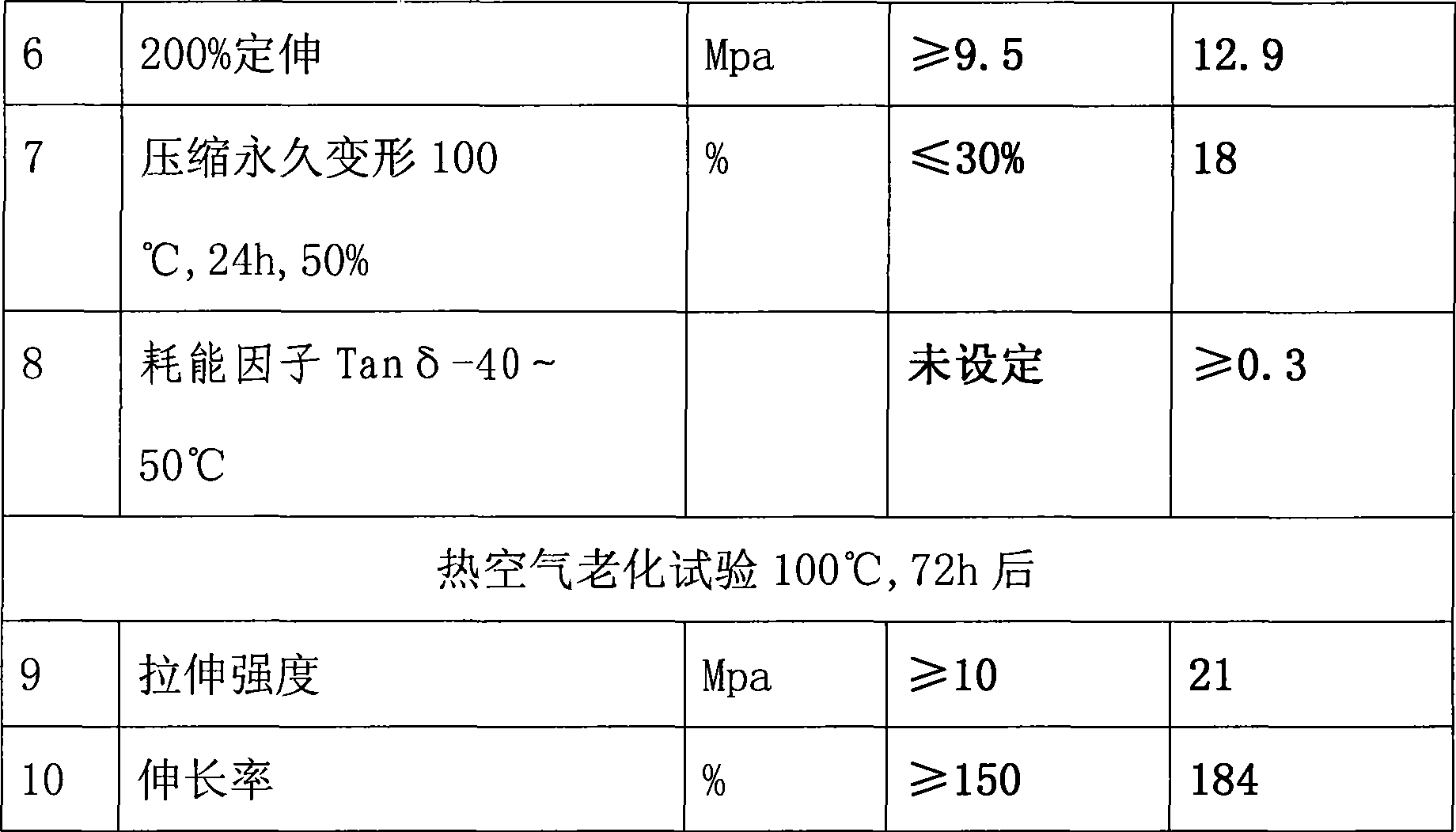

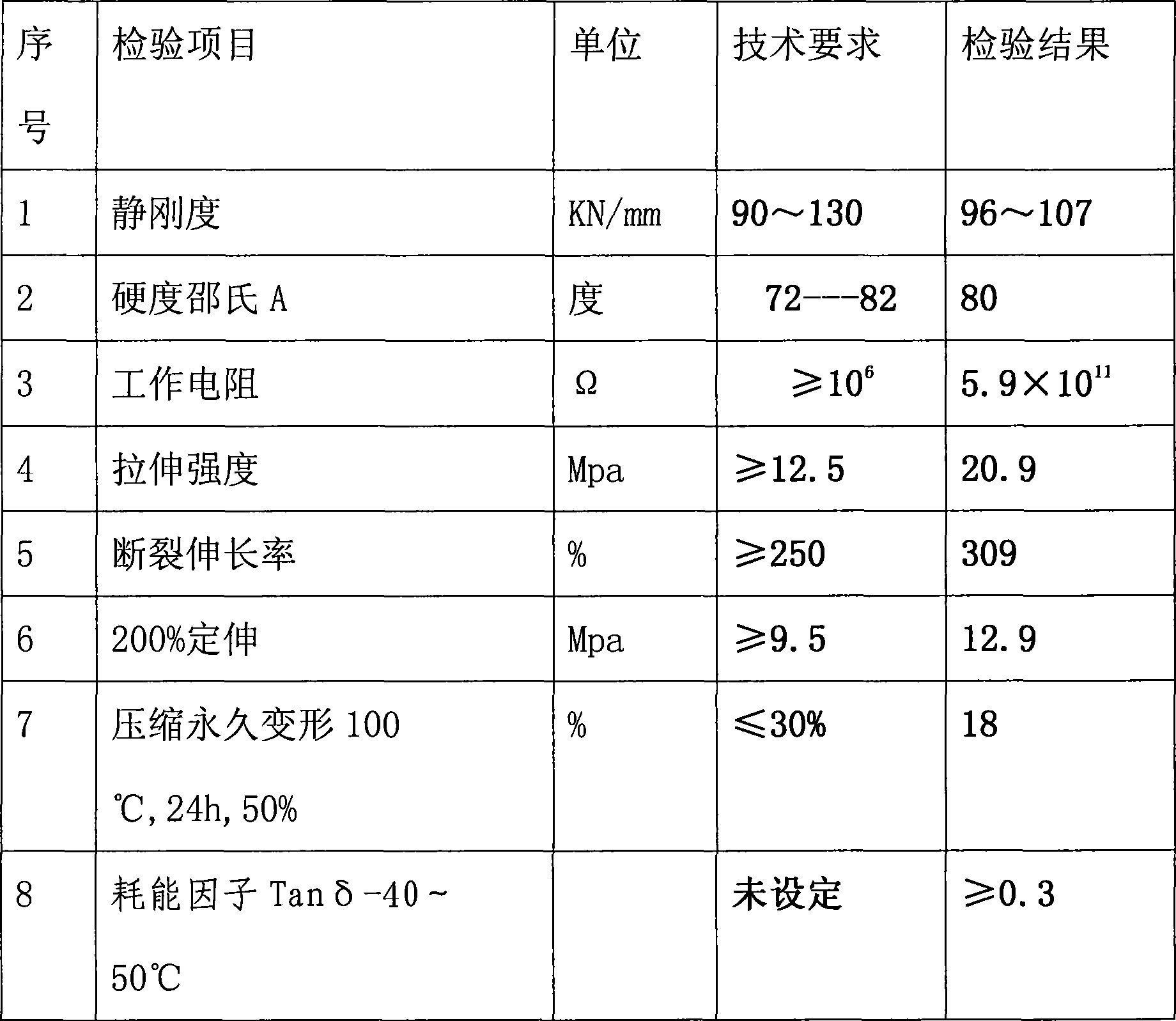

Image

Examples

specific Embodiment 1

[0006] Weigh each material in the formula, and the specific unit is kilogram Natural, styrene-butadiene rubber, styrene polymer: 60, halogenated butyl rubber: 20, regenerated halogenated butyl rubber, regenerated bromobutyl rubber: 20, zinc oxide: 4. Stearic acid: 2, amine antioxidant: 2.0, sulfenamide accelerator: 8, thiazole accelerator: 1.0, thiuram accelerator: 1.0, petroleum resin: 20, carbon black: 40, Silica: 30, silane coupling agent: 3, sulfur: 1.5.

[0007] Compounding: Weigh all kinds of rubber and additives in the formula according to the ratio for use, and the accelerator and sulfur should be weighed more accurately;

[0008] Mixing: The initial temperature of the internal mixer is 100-110 ° C, 60 rpm, first add natural and synthetic rubber, mix for 2 minutes, add chlorinated and brominated butyl reclaimed rubber, and mix for 2 minutes; then add ZnO , white carbon black, silane coupling agent was added, mixed for 3 minutes, finally added sulfenamide accelerator, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com