Phase-change radiating device

A heat-dissipating device and phase-change technology, applied in indirect heat exchangers, lighting and heating equipment, lasers, etc., can solve the problems of low heat dissipation efficiency, large volume, and reduced beam quality, and achieve improved heat dissipation efficiency, improved luminous efficiency, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

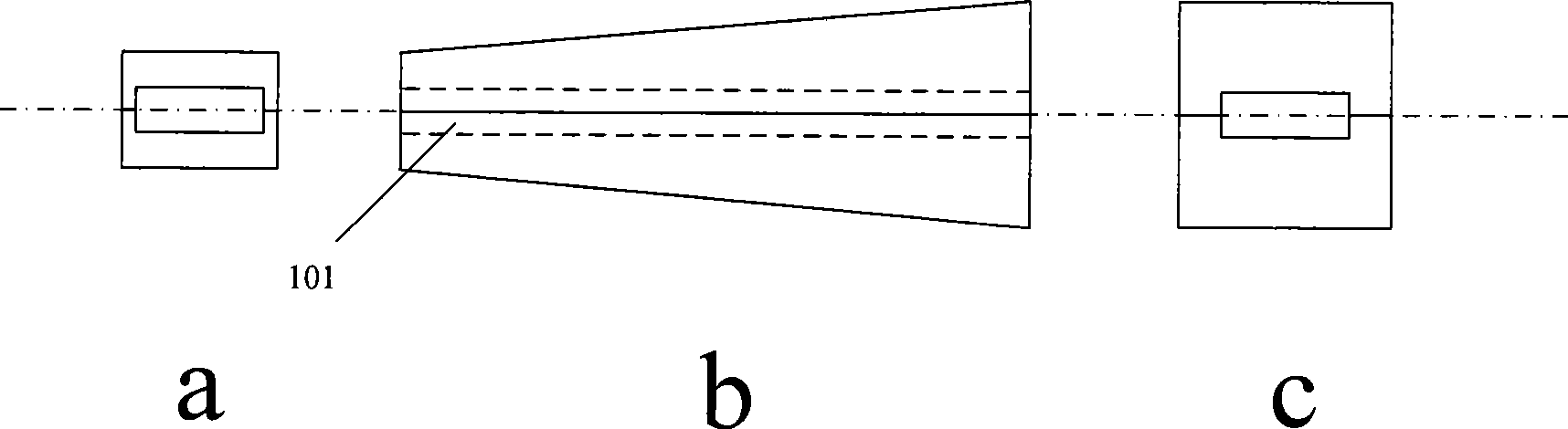

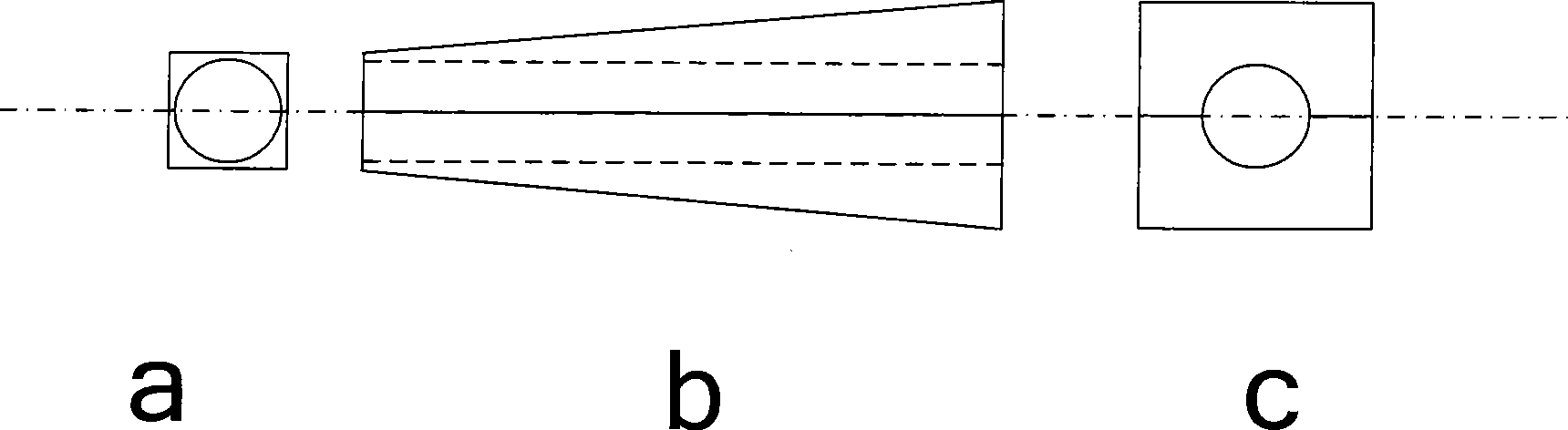

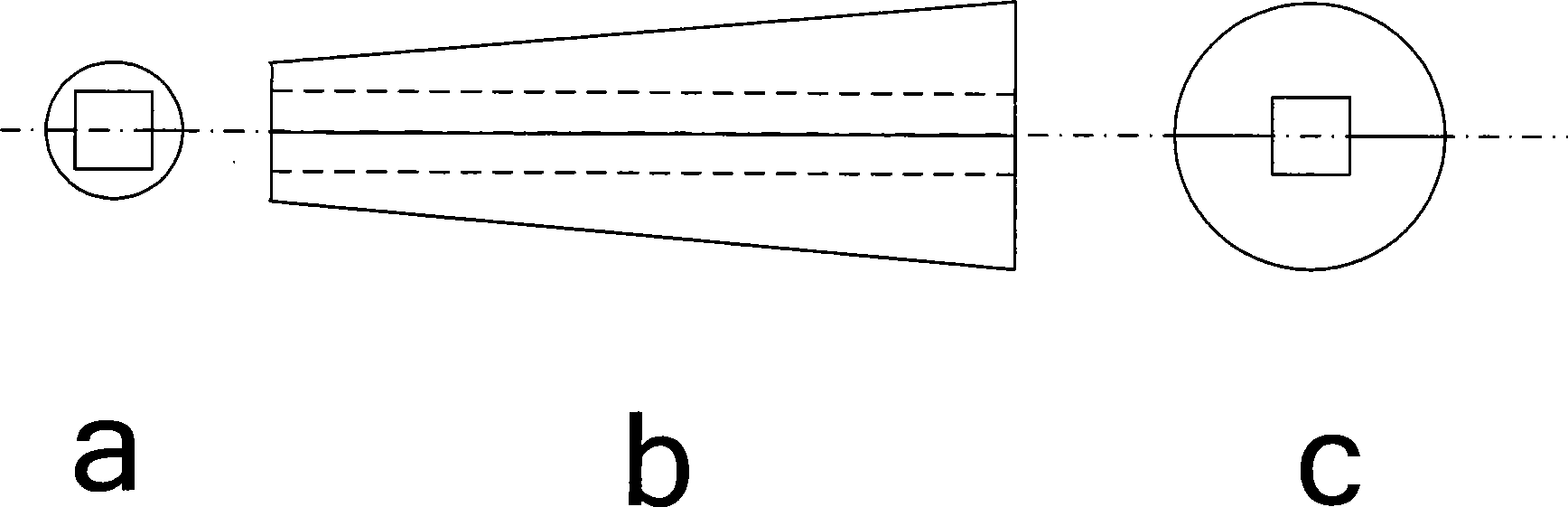

[0028] Figure 1-Figure 4 It is a schematic diagram of four kinds of heat-absorbing component structures in the phase change heat dissipation device.

[0029] Figure 1-Figure 2 It is two kinds of heat-absorbing components of quadrangular truss, whose cross-sections are rectangular and square respectively. image 3 and Figure 4 There are two types of conical heat-absorbing components whose cross-section is circular, such as Figure 1-Figure 4 As shown, the heat-dissipating object 101 is surrounded by heat-absorbing components, which can quickly and effectively conduct the generated heat away, wherein, Figure 1-Figure 3 The objects to be radiated are flakes, rods and blocks, Figure 4 The objects to be dissipated are also block-shaped. Such as figure 1 b- Figure 4 As shown in b, since the side section of the heat-absorbing component is wedge-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com