Water-soluble gel for removing decay on decayed tooth and method for producing the same

A manufacturing method and water-soluble technology, applied in dental preparations, pharmaceutical formulations, pharmaceutical sciences, etc., can solve problems such as time-consuming, inability to cure the root cause, drug resistance, etc., to reduce the risk of pulp penetration, accurate caries removal, and strong dissolution. The effect of the ability of organics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

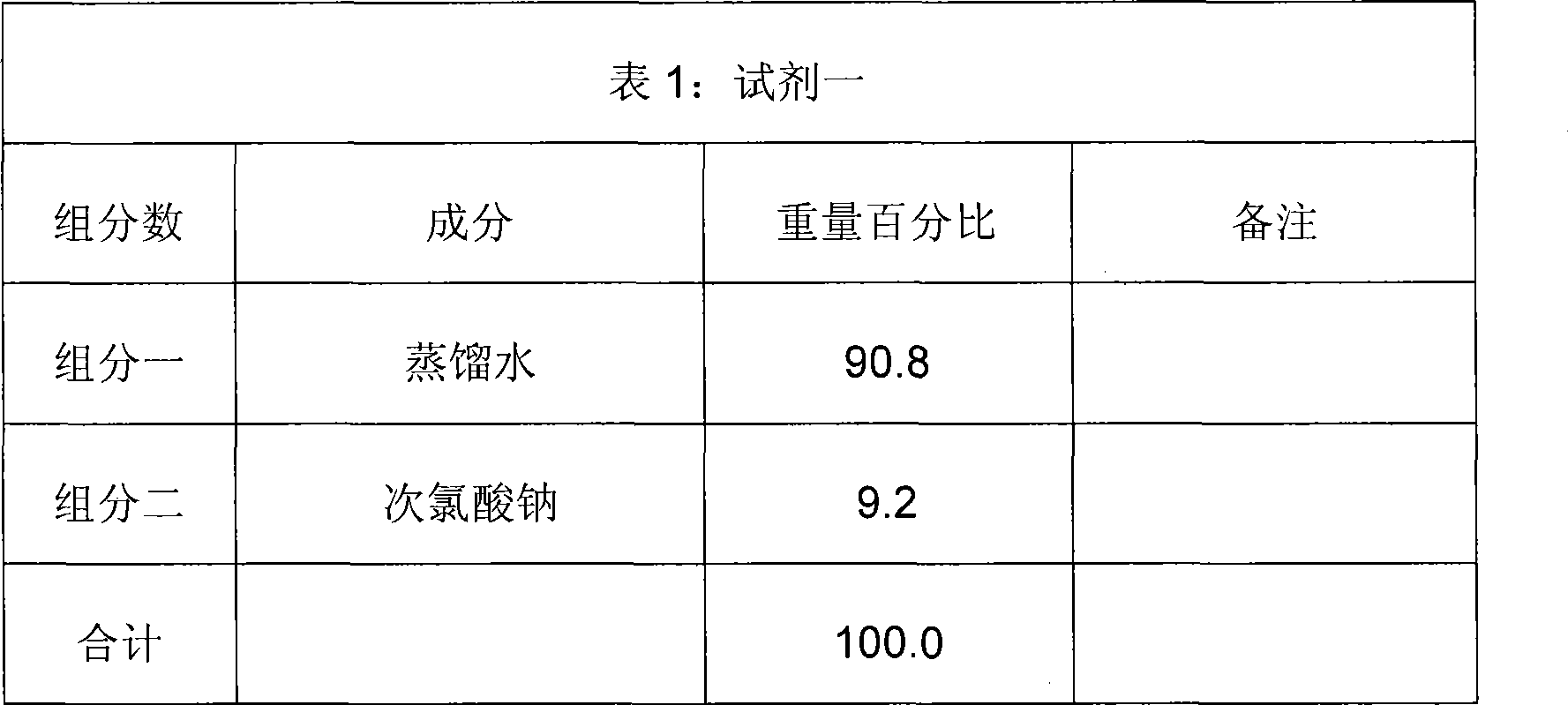

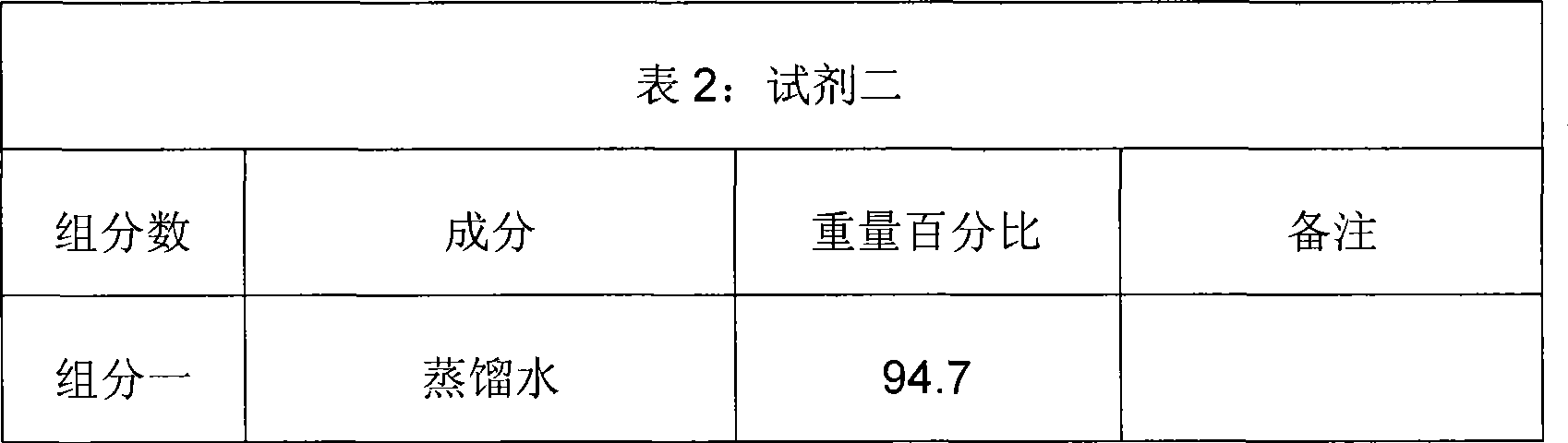

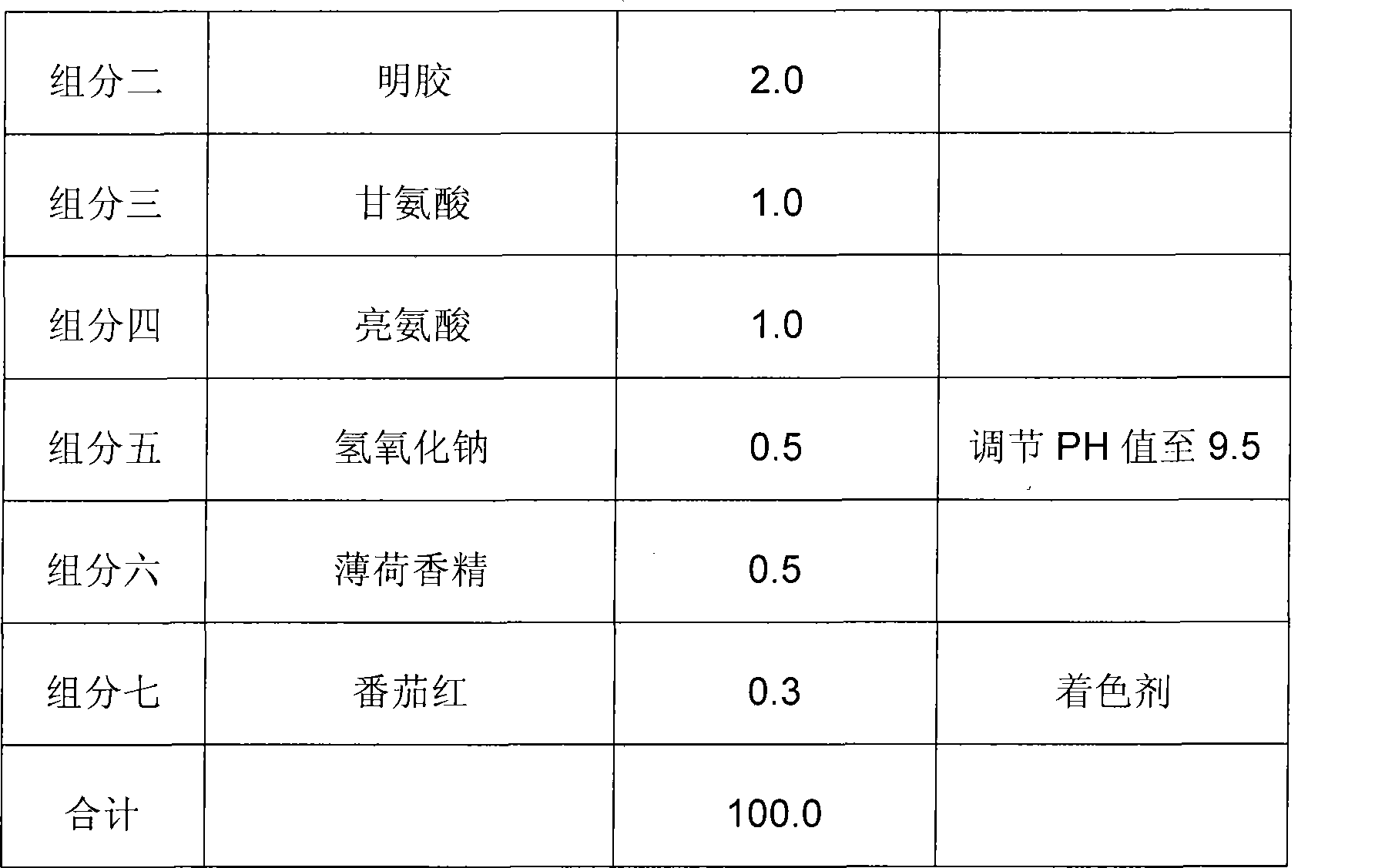

[0037] The formula of reagent one and reagent two of the present invention is as shown in table 1, table 2:

[0038]

[0039]

[0040]

[0041] Its manufacturing method and steps are as follows:

[0042] Preparation of reagent 1: Accurately weigh each raw material in a beaker according to the above formula ratio, and set aside; add distilled water into the stirring pot, and turn on the stirrer; after the stirrer speed stabilizes, add the caries-removing active ingredient into the stirring pot , stir for 30-50 minutes until the solution is clear; pour the above solution into a pre-prepared packaging tube and seal it.

[0043] Preparation of reagent 2: Accurately weigh each raw material in a beaker according to the formula ratio, and set aside; add distilled water into the stirring pot, and turn on the stirrer; 30 minutes until the solution is clear; when the solution is clear, add the viscosifier into the stirring pot in batches and stir for 50-90 minutes. After the s...

Embodiment 2

[0050] The formula of reagent one and reagent two described in this embodiment is as shown in table 3 and table 4:

[0051]

[0052]

[0053]

[0054] The manufacturing method and usage method of this embodiment are the same as that of Embodiment 1.

Embodiment 3

[0056] The formula of reagent one and reagent two described in the present embodiment is as shown in table 5 and table 6:

[0057]

[0058]

[0059]

[0060] The manufacturing method and usage method of this embodiment are the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com